Welding method for welded joints

A welding method and welding direction technology, which is applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of weld shrinkage and other problems, and achieve the effects of improving the forming coefficient, rapid discharge, and reducing time difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In the following, the present invention will be more clearly and completely described by means of preferred embodiments in conjunction with the accompanying drawings, but the present invention is not limited to the scope of the described embodiments.

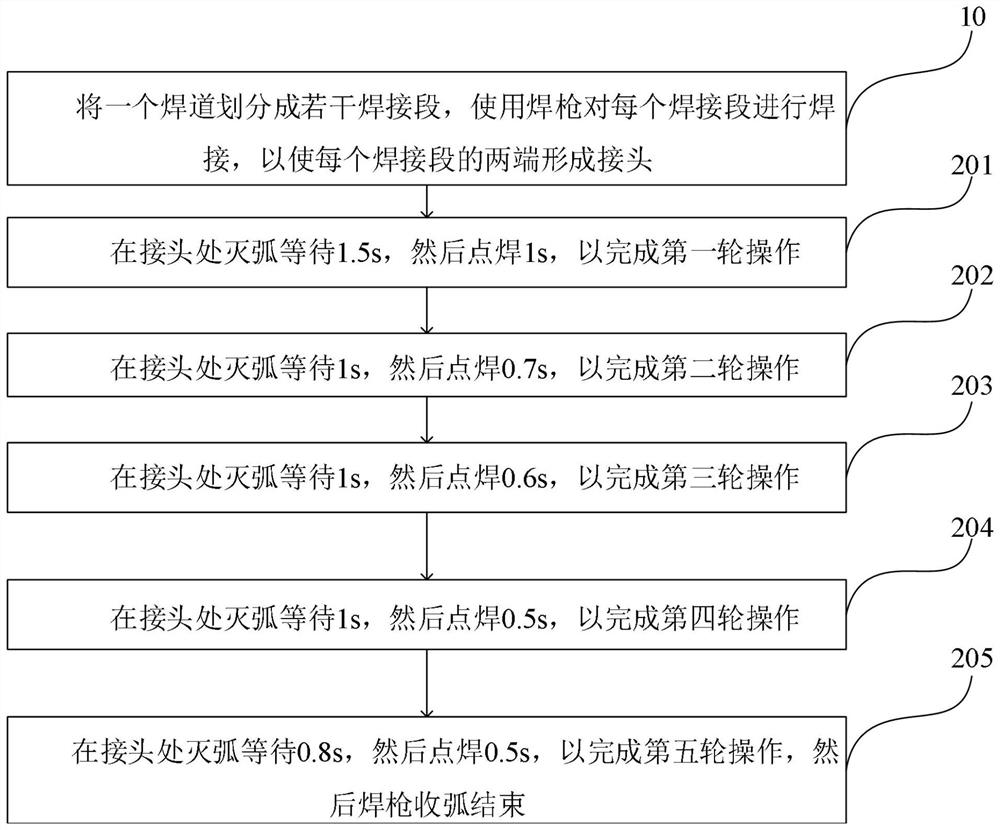

[0032] The invention provides a welding method for a welded joint, which comprises the following steps:

[0033] Step 10, dividing a welding bead into several welding sections, using a welding torch to weld each welding section, so that the two ends of each welding section form a joint;

[0034] Step 20, using a continuous arc extinguishing method at the joint, so that the time difference between the solidification of the surface metal and the underlying metal at the joint is between 0.3s and 0.7s. The continuous arc extinguishing method refers to: when the welding torch is welded to the joint, the arc extinguishing and spot welding operations are performed at intervals at the joint, and the arc extinguishing is completed...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap