Spinning assembly and spinning method thereof

A spinning component and spinning technology, applied in the field of spinning component and its spinning, can solve the problems of spinning breakage, affecting the drawing state, and breaking of filaments, so as to achieve uniform crystallization of filaments, prevent local crystallization, and prevent heat loss. loss of uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

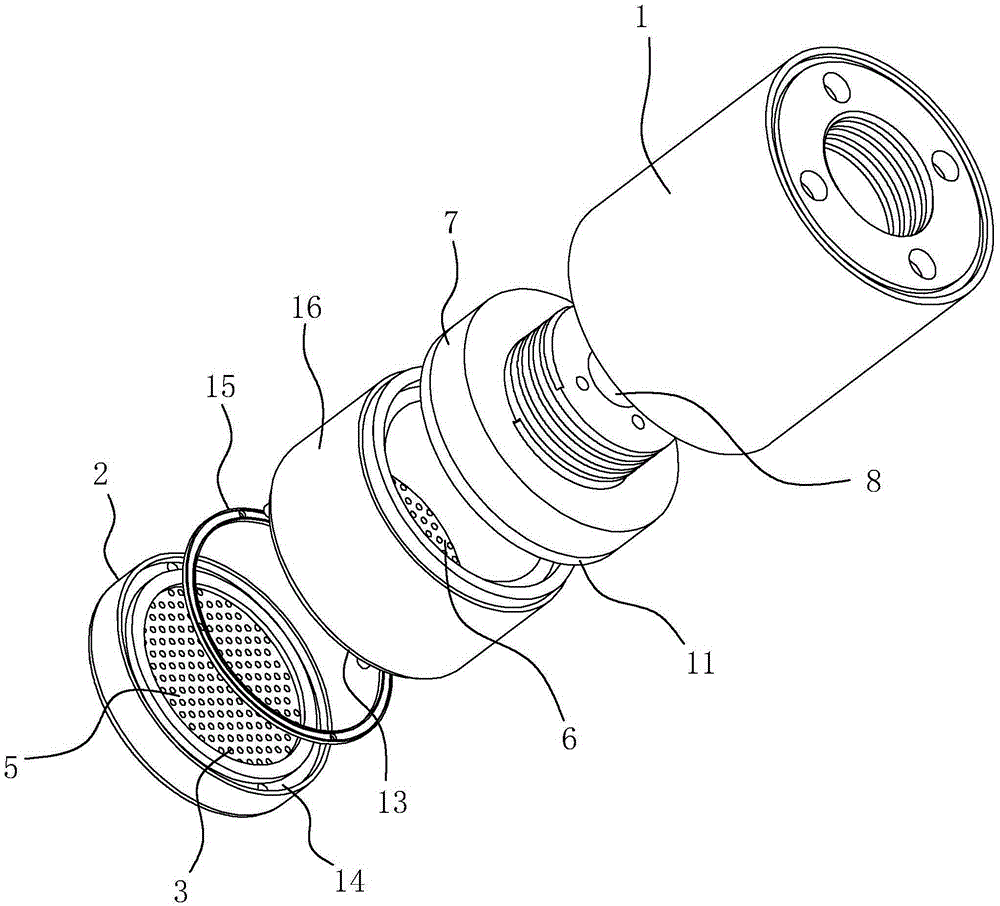

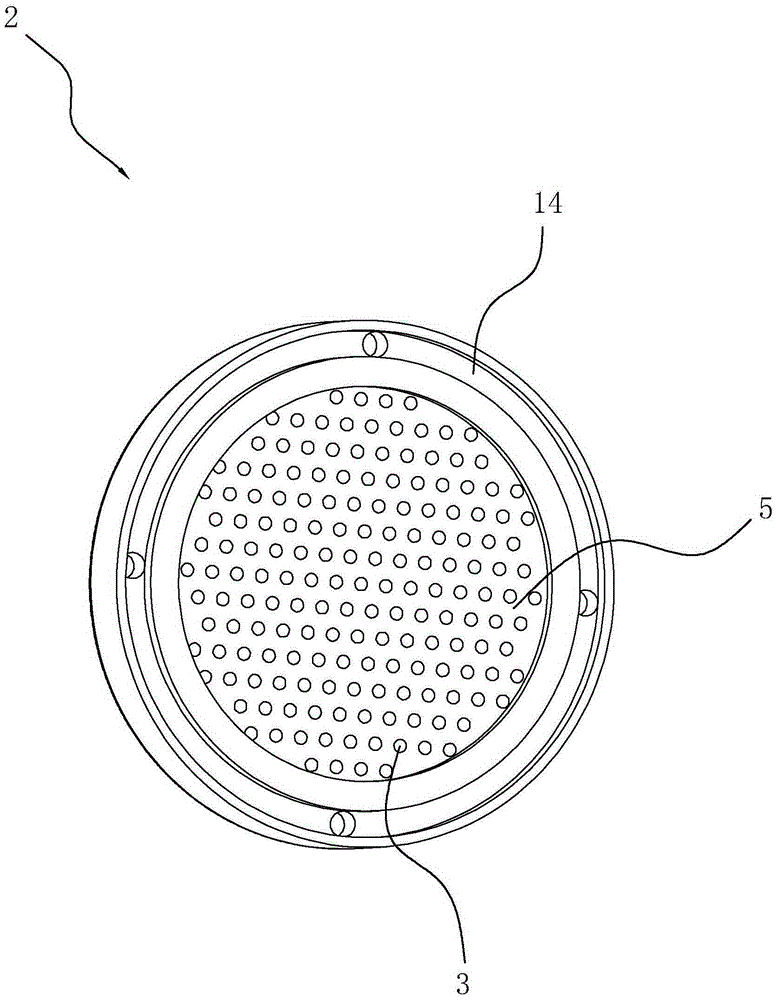

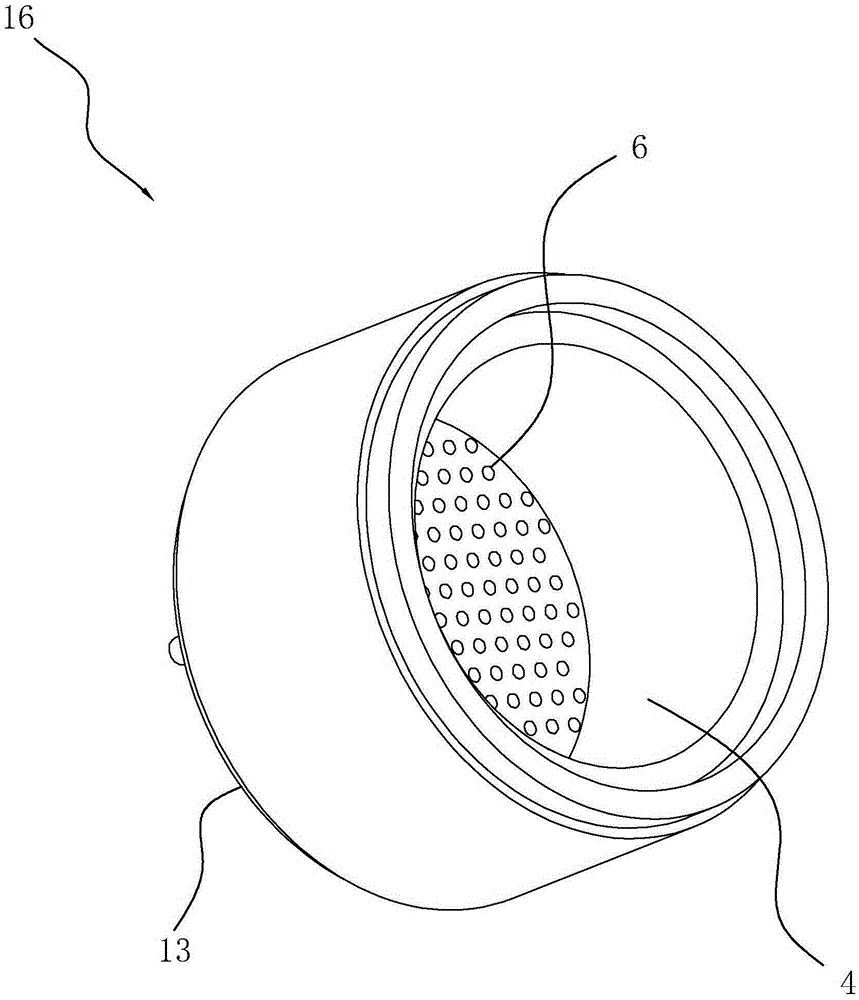

[0035] refer to Figure 1~6 The present invention will be further described.

[0036] Such as Figure 1~5 As shown, a spinning assembly includes a tank 1 and a spinneret 2 arranged at the bottom of the tank 1, the spinneret 2 is provided with at least one spinneret 5 and the spinneret 5 is evenly provided with a plurality of spinnerets The holes 3 and the upper side of the spinneret 2 are sealed and connected with an accommodation chamber for accommodating the fluid. The accommodation chamber is evenly divided into at least one distribution chamber 4. The distribution chamber 4 corresponds to the spinneret area 5 one by one. There is a filter plate 6, and above the accommodating chamber, there is a flow block 7 for the fluid to enter the distribution chamber 4. The flow block 7 is provided with a main flow channel and a plurality of flow channels 8, and the fluid outlets of the flow flow blocks 8 9 corresponds to the distribution chamber 4, the horizontal section of the dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com