Sound screen cloth and mold thereof

A sound and mold technology, applied in the field of textiles, can solve the problems of cumbersome operation and low work efficiency, and achieve the effect of ensuring stable production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

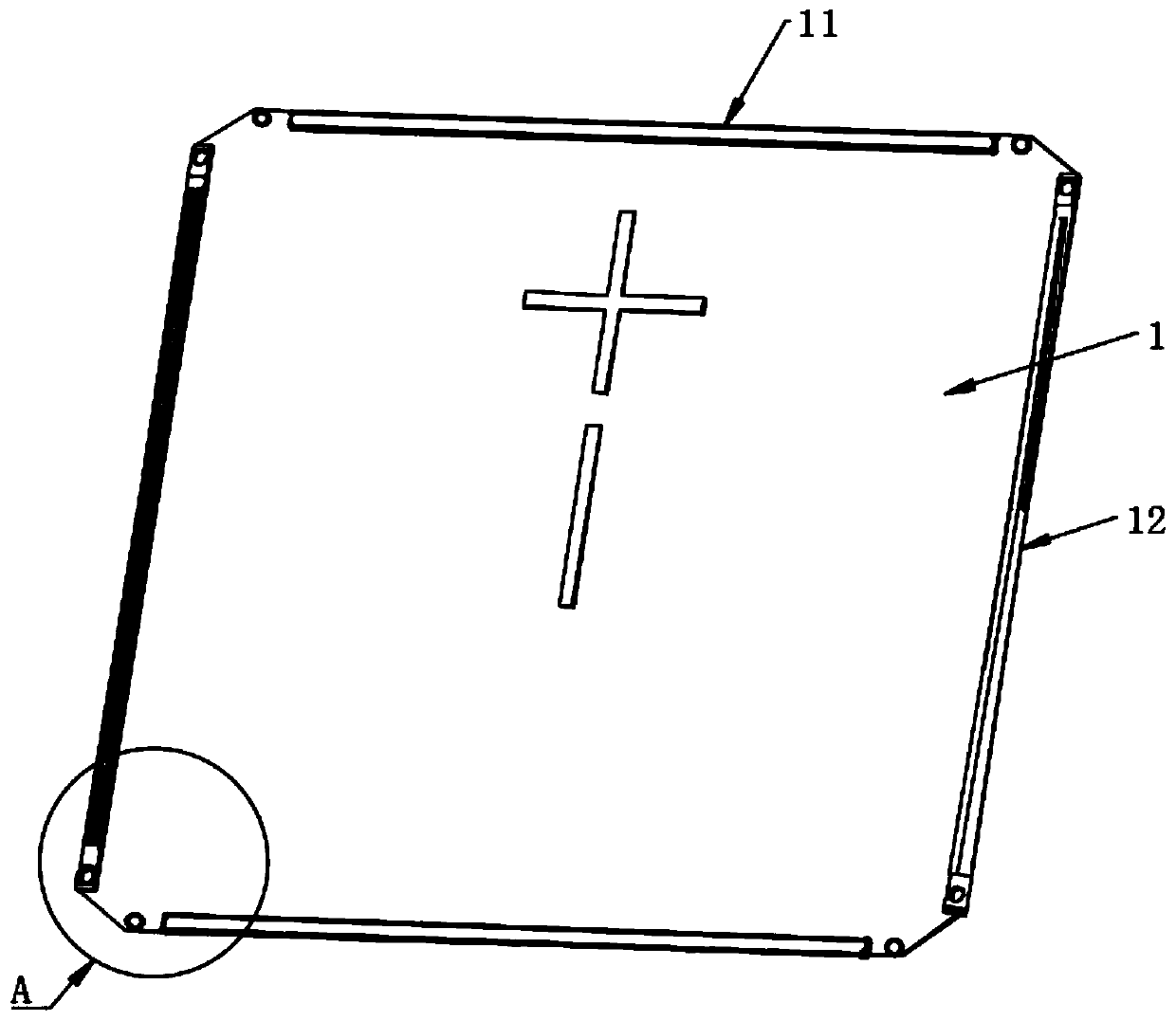

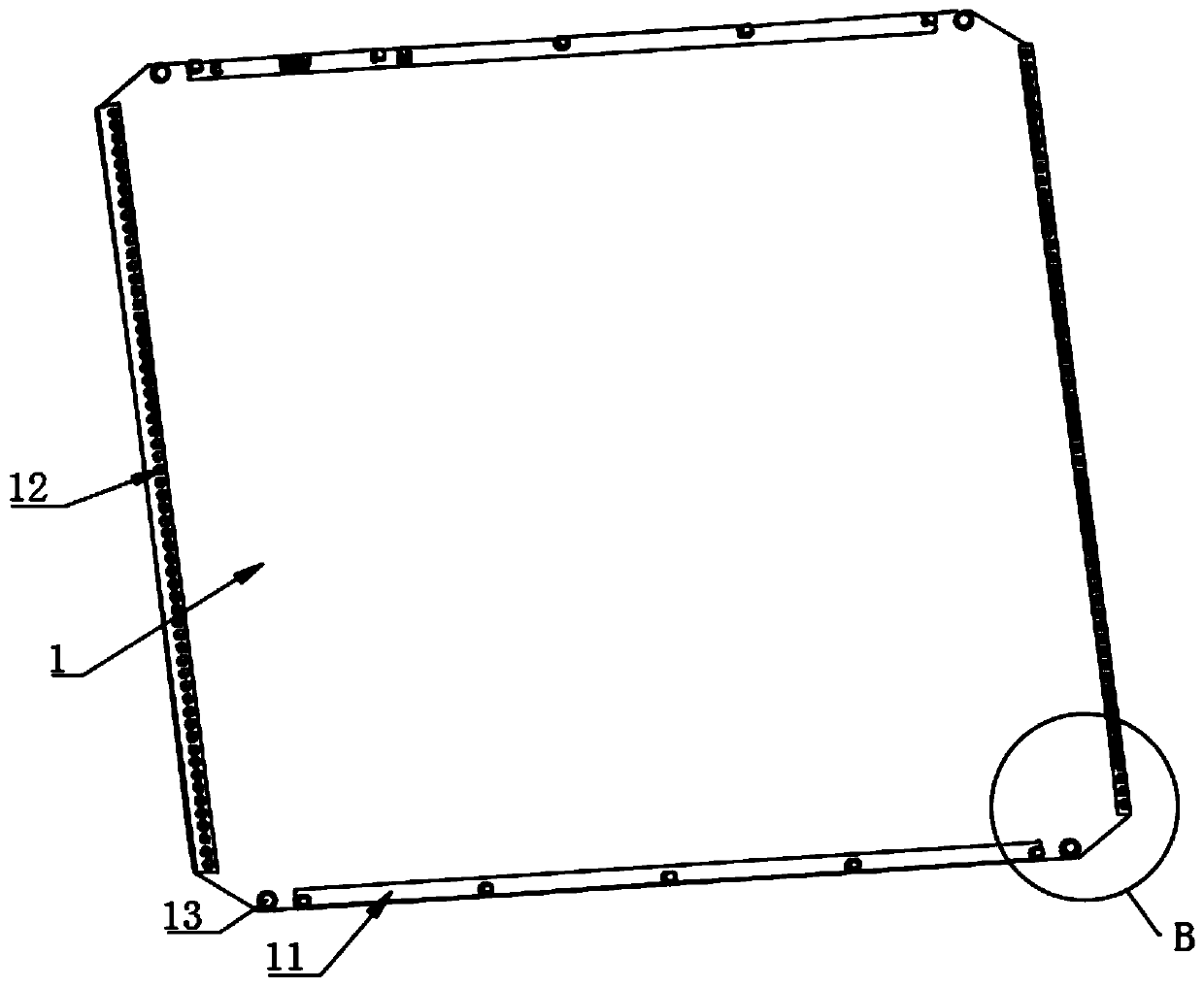

[0035] Embodiment: a kind of acoustic net cloth, as figure 1 As shown, including the cloth body 1, the two long side edges of the cloth body 1 are respectively provided with a fixed strip 11, and the two wide side edges of the cloth body 1 are respectively provided with a fixed strip 2 12, and the distance between the two fixed strips 12 is greater than the length of the first fixing bar 11, and the distance between two fixing bars one 11 is greater than the length of the second fixing bar 12.

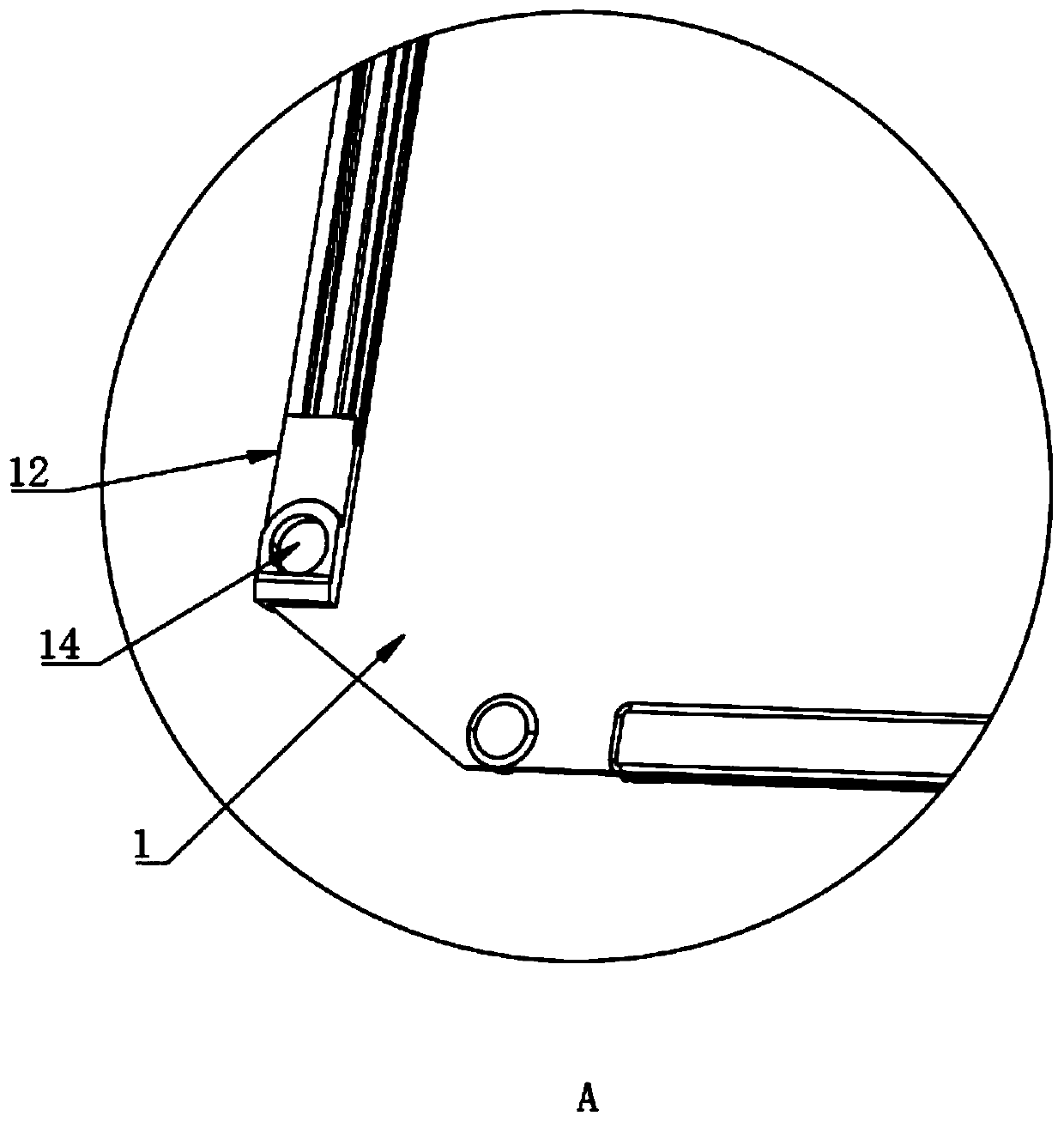

[0036] Such as figure 2 with Figure 4 As shown, a card column 13 is respectively arranged outside the two ends of the length direction of each fixing bar 11, and the two ends of the length direction of each fixing bar 12 are provided with a draw-in groove 14 for the card post 13 to snap into. 11. The second fixing bar 12 and the clamping column 13 are formed by plastic injection molding, and the clamping groove 14 and the clamping column 13 are on the front and back of the cloth bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com