Prestressed steel strand fixing frame and mounting and using method thereof

A technology of prestressed steel strands and fixing frames, which is applied in the field of placing devices before steel strands are unloaded, and in the field of prestressed steel strands fixing frames, and can solve the problem of inability to adjust and properly place steel strand coils and steel strands Unable to ensure the quality of the project, the overall stability of the fixing frame is poor, etc., to achieve the effect of saving materials, simple structure, and speeding up the transmission speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

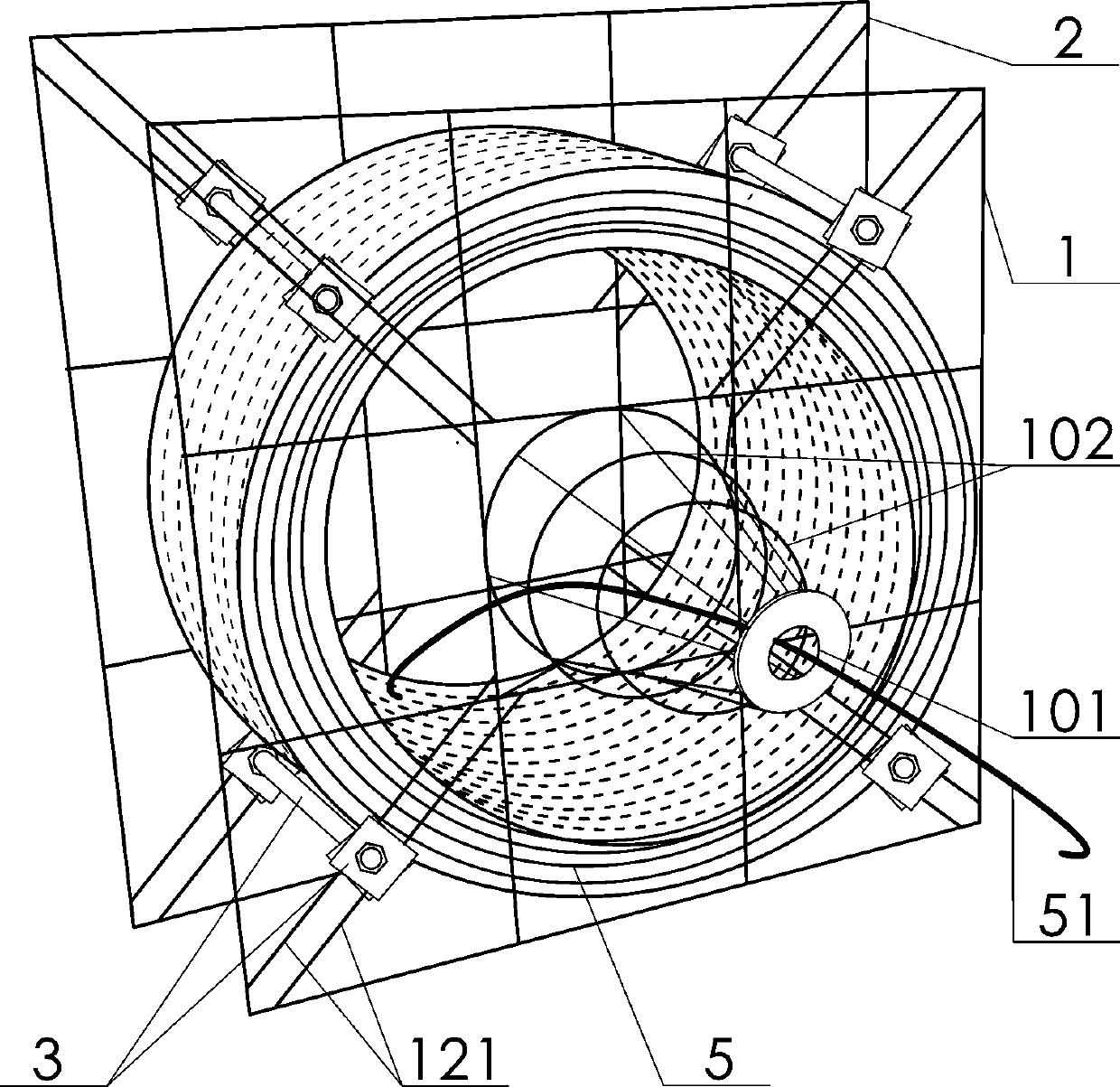

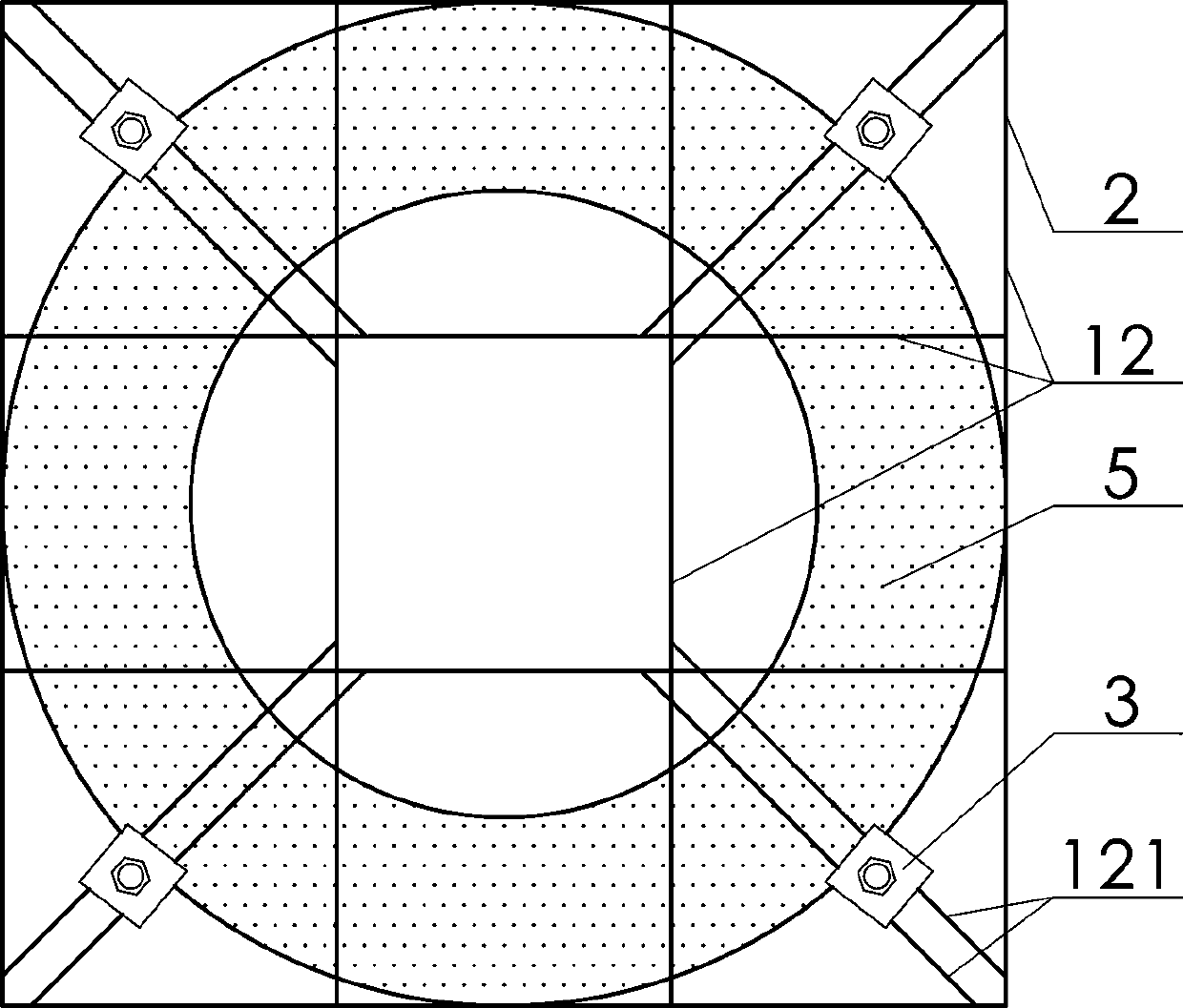

[0038] like figure 1 As shown, a prestressed steel strand fixing frame of the present invention includes a first sheet frame 1, a second sheet frame 2, and a sliding limit fixing assembly 3; the first sheet frame 1 and the second sheet frame 2 are both It is square, with the same four sides, and the faces are parallel to each other. There are a number of limit rails 121 that are installed in conjunction with the sliding limit fixing assembly 3, and are fixed and installed with the sliding limit fixing assembly 3 to form a storage space for the steel strand coil 5. ; The central position of the first sheet frame 1 is provided with a steel strand lead-out hole 101 along the through direction, and the inner diameter of the steel strand lead-out hole 101 is adapted to the wire diameter of the steel strand 51 .

[0039] During use, by adjusting the installation position of each sliding limit fixing assembly 3 on the limit track 121 of the first sheet frame 1 and the second sheet fr...

Embodiment 2

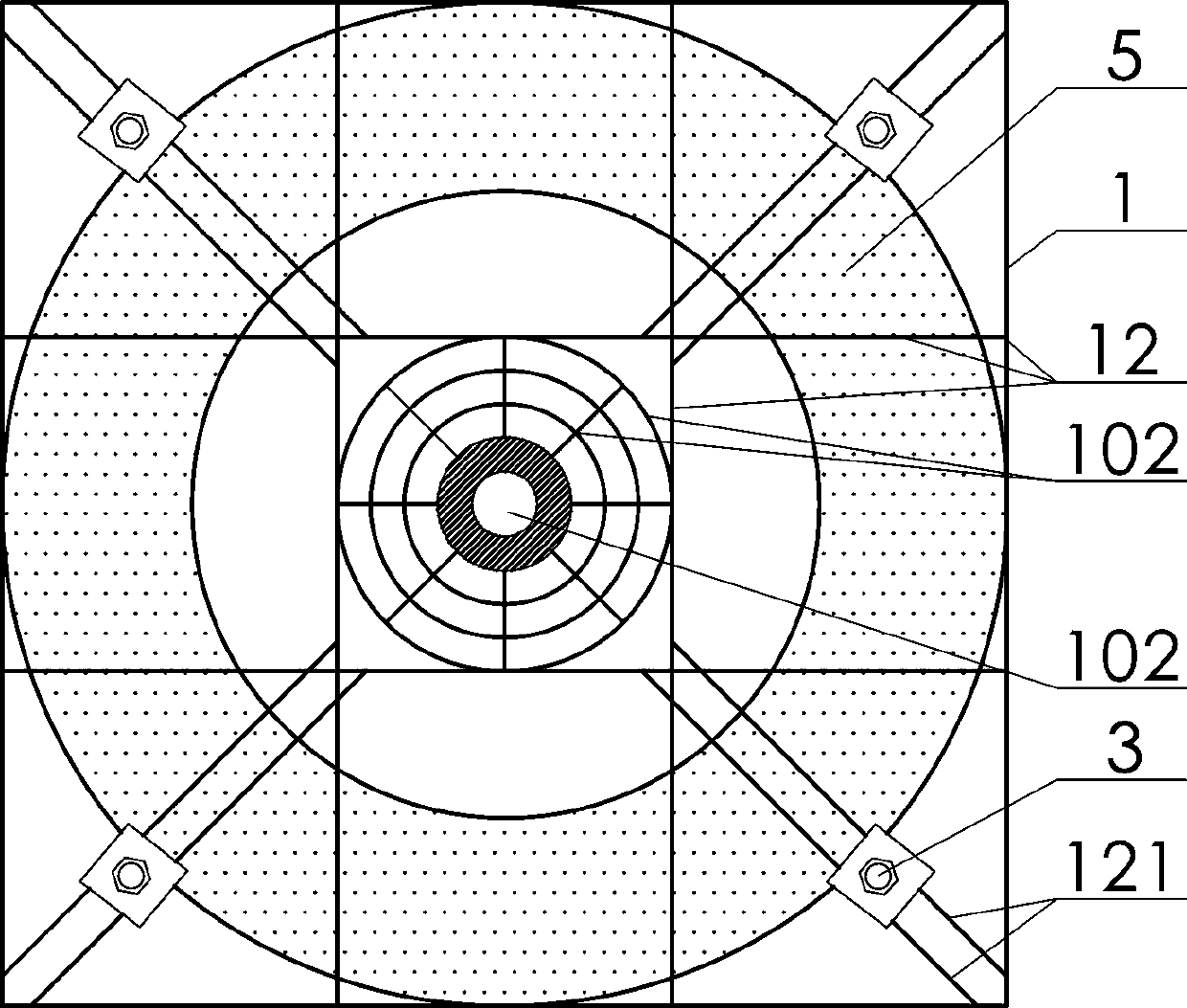

[0048] like Figure 5 , Image 6 As shown, a kind of prestressed steel strand fixing frame of the present invention is on the basis of embodiment 1, and the central position of described first frame 1 is provided with bearing 4 along the through direction, and the axis of described bearing 4 and The axes of the placed steel strand coils 5 coincide, and the core hole of the inner ring of the bearing 4 is the steel strand lead-out hole 101; the bearing 4 is an inseparable angular contact ball bearing with an outer diameter of 50 mm.

[0049] Bearing 4 is set at steel strand lead-out hole 101 places, rotates by bearing 4, can reduce the friction of prestressed steel strand 51 and the reinforcing bar of lead-out hole position, reduce steel strand 51 wearing and tearing, prevent the damage of steel strand 51, ensure Engineering quality; at the same time, the twisting force of the steel strand 51 is reduced by the rotation of the bearing 4 to prevent the bending and breaking of the...

Embodiment 3

[0051] The method for installing and using the prestressed steel strand fixing frame of Embodiment 1 and Embodiment 2 of the present invention is as follows.

[0052] S1. First remove the outer packaging of the prestressed steel strand coil 5, then place the first frame 1 and the second frame 2 on both sides of the steel strand coil 5, and place the sliding limit fixing assembly 3 on the first frame 1. The second frame 2 cooperates with the fixed installation to form a storage space for the steel strand coil 5 .

[0053] S2. By adjusting the installation position of each sliding limit fixing assembly 3 on the limit track 121 of the first sheet frame 1 and the second sheet frame 2, the center of the steel strand lead-out hole 101 is located on the axis of the steel strand coil 5 , the steel strand coil 5 is placed in a suitable position.

[0054] S3. Cut off the iron strip that binds the steel strand coil 5 horizontally, remove the horizontal iron strip, find the inner steel s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com