Pantograph conductor height and stagger value measuring method based on monocular image

A measurement method and pantograph technology, applied in the direction of measuring devices, instruments, optical devices, etc., to achieve the effects of low cost, improved accuracy, and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

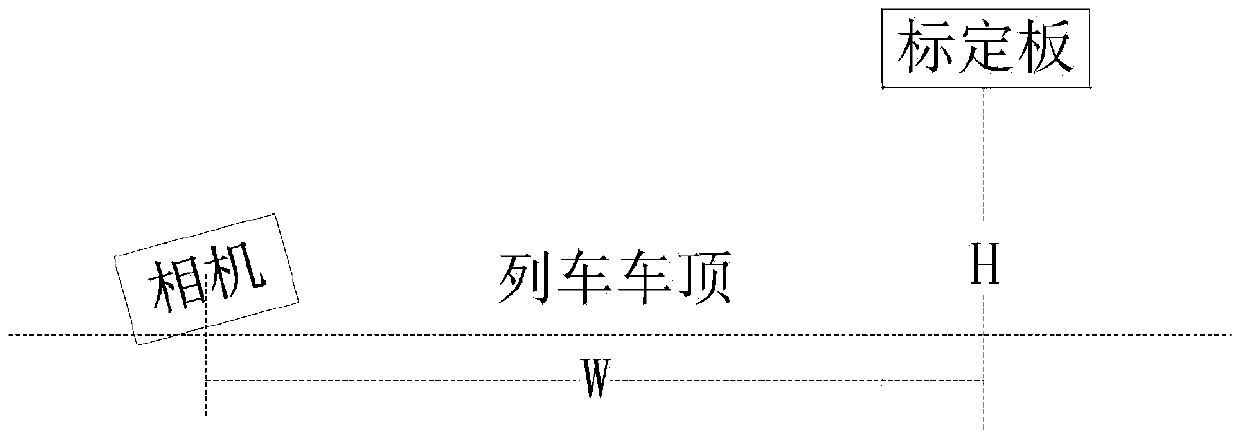

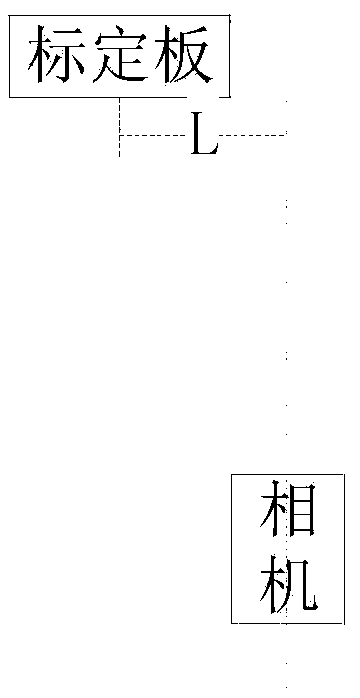

[0059] like Figure 1-16 As shown, a method for measuring pantograph conductance and pull-out value based on monocular images, the method includes the following steps:

[0060] Step 1: Install the roof hardware equipment, which includes industrial cameras, strobe fill lights and control panels; the images of the industrial cameras are transmitted to the vehicle-mounted industrial computer for pull-out value and guide height calculation;

[0061] Step 2: Install the bottom vibration compensation module, the roof vibration compensation module is two laser triangulation ranging modules; the laser triangulation ranging module measures the height of the train chassis from the rail in real time, and transmits the height to the on-board industrial computer;

[0062] Step 3: Calibrate the industrial camera; the specific calibration steps are:

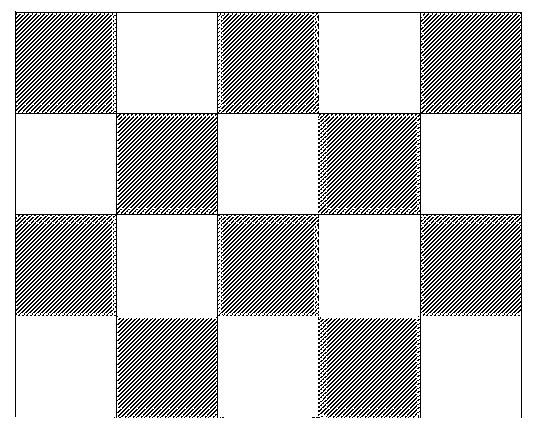

[0063] S1: Select a suitable calibration board to calibrate the industrial camera image;

[0064] S2: Place the calibration chessboard in fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com