A kind of blade defect detection method and maintenance method

A defect detection and blade technology, which is applied in the direction of optical defect/defect test, measuring device, instrument, etc., can solve problems such as false detection, and achieve the effect of high detection accuracy and small error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

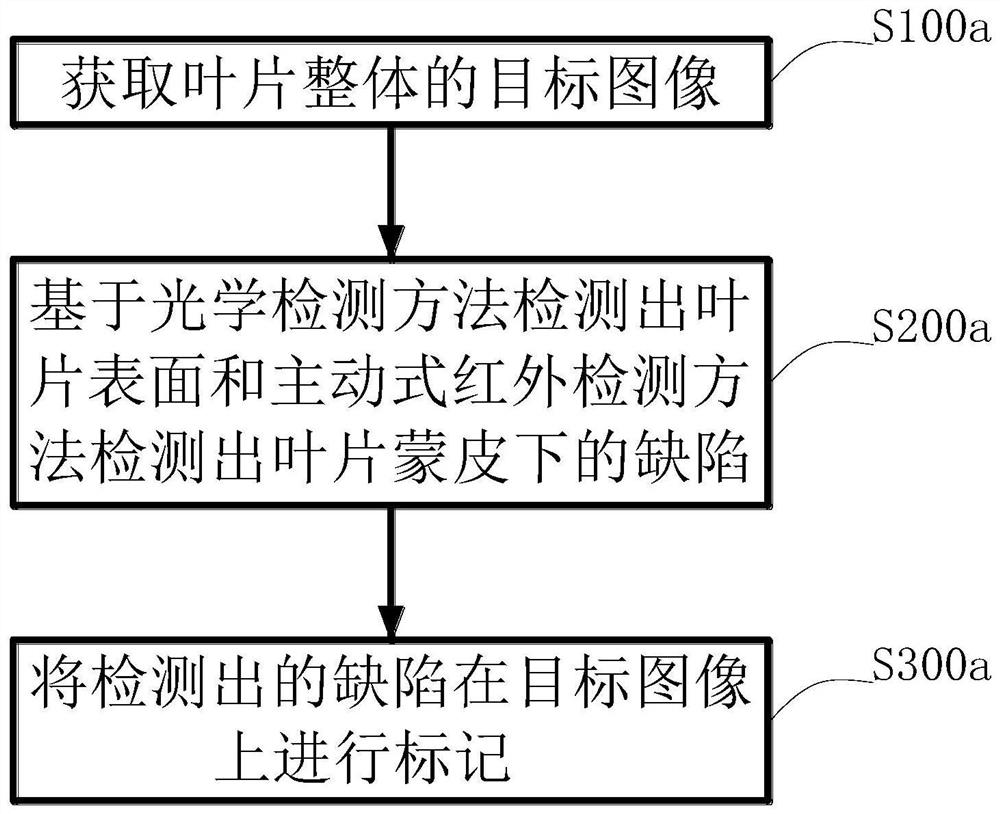

[0031] Such as figure 1 As shown, a blade defect detection method includes the following steps:

[0032] S100a. Acquiring an overall target image of the blade;

[0033] S200a. Detecting the surface of the blade based on an optical detection method and detecting defects under the skin of the blade by an active infrared detection method;

[0034] S300a. Mark the detected defects on the target image.

[0035] If the step S100a cannot be completed at one time when acquiring the target image of the whole blade, multiple images of the blade can be collected, and then these multiple photos are spliced to obtain the target image of the whole blade.

[0036] The step S300a is specifically as follows:

[0037] S310a, ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com