Rising breaking assembly for beverage extraction device

An extraction device and bursting technology, applied in the field of bursting components for beverage extraction devices, can solve the problems of unfavorable sealing silica gel clamping capsules and synchronous backward movement, easy deformation, detachment, etc., to solve the problem of capsule adsorption and difficult detachment, structure Simple and versatile effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

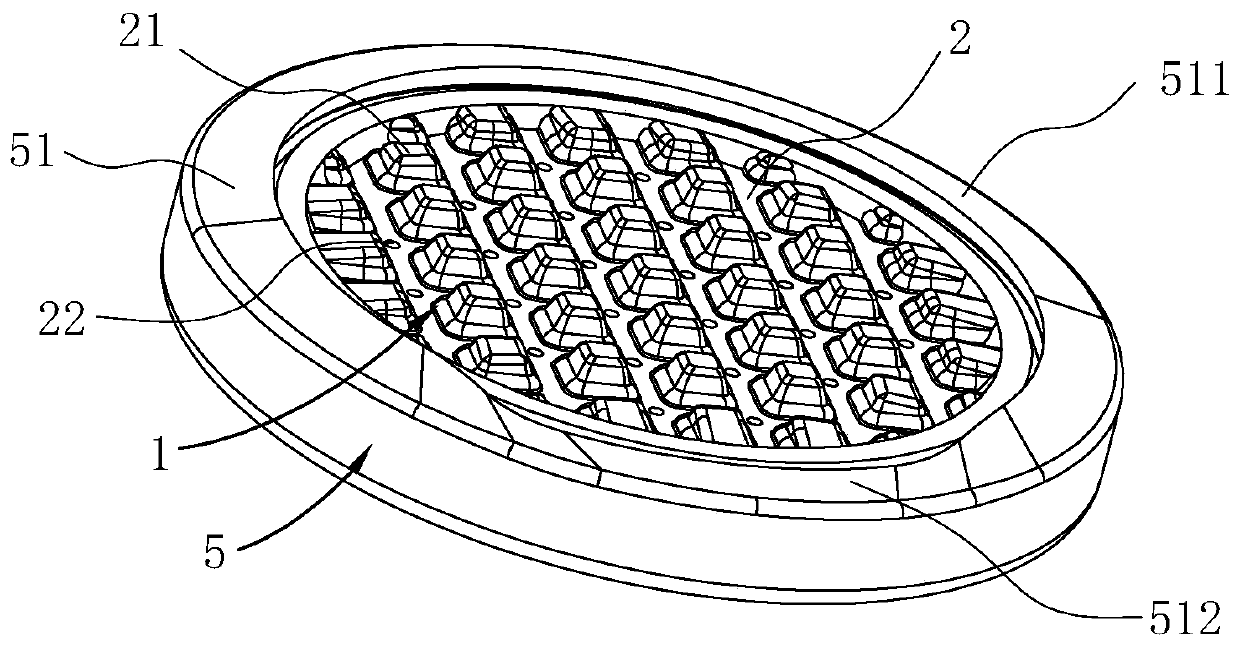

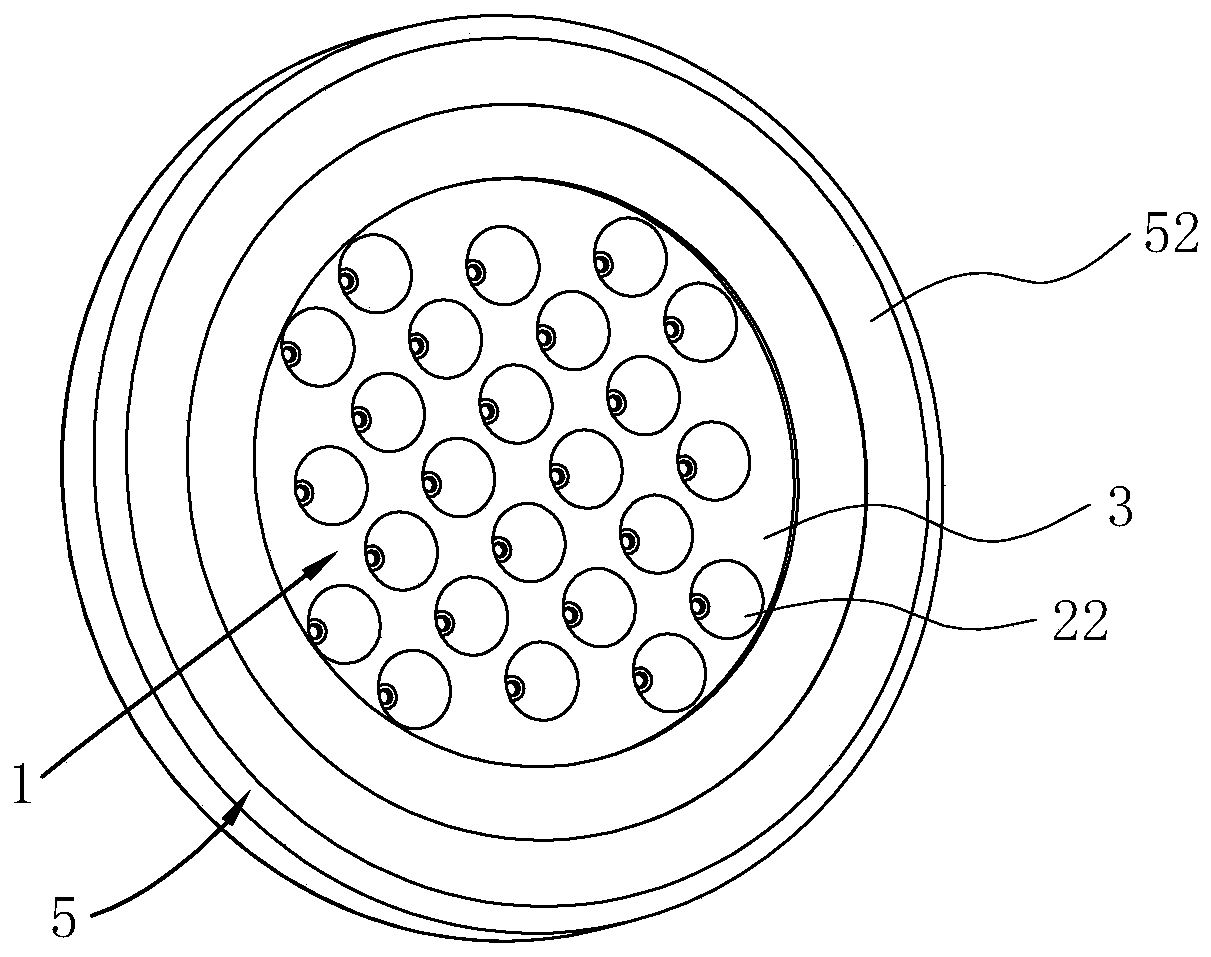

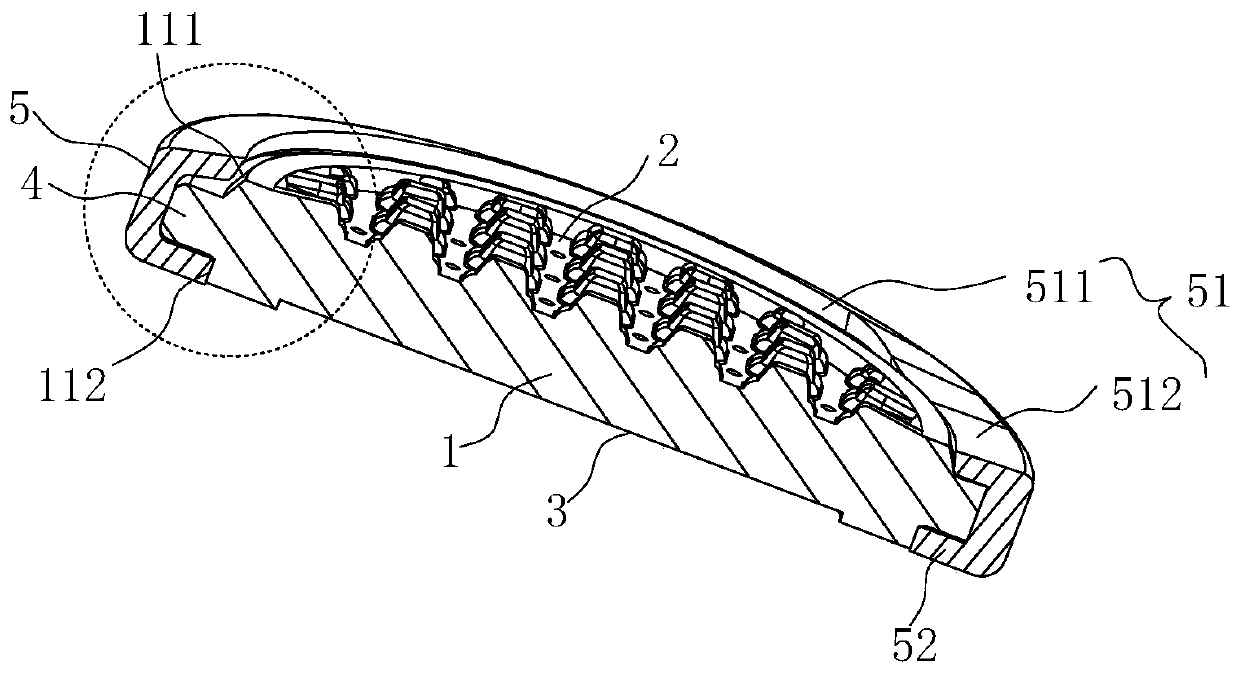

[0029] refer to Figure 1 to Figure 6 As shown, it is a preferred embodiment of the present invention, which provides a burst assembly for a beverage extraction device. see details figure 1 and figure 2 , the bursting assembly includes a bursting plate 1 having a first end face 2 and a second end face 3, the bursting plate 1 is provided with a plurality of bosses 21 and a plurality of liquid outlet holes 22 penetrating through the bursting plate 1, Wherein, the bosses 21 are arranged in an array on the first end face 2, the bottom between two adjacent rows of bosses 21 forms a transverse channel for the beverage to flow, and the bottom between two adjacent rows of bosses 21 forms a flow channel for the beverage to flow. In the vertical channel for the beverage to flow, each liquid outlet hole 22 is respectively arranged at the junction of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com