Uniformly-mixing equipment of coating polyester film coating liquid for enhancing UV printing bonding force

A technology of polyester film and bonding force, applied in the field of mixing device for coating polyester film coating liquid to enhance UV printing bonding force, can solve the problems of unstable UV ink, low manufacturing risk, physical discomfort of staff, etc. The effect of uniform and stable discharging process, prevention of physical discomfort and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following will be combined with Figure 1-8 The present invention is described in detail, and the technical solutions in the embodiments of the present invention are clearly and completely described. Apparently, the described embodiments are only some of the embodiments of the present invention, not all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

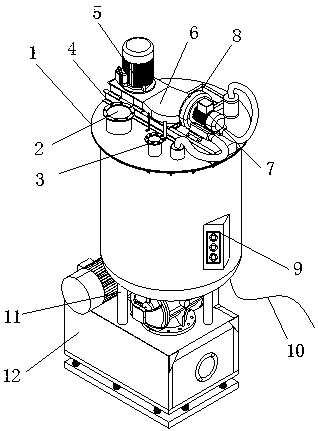

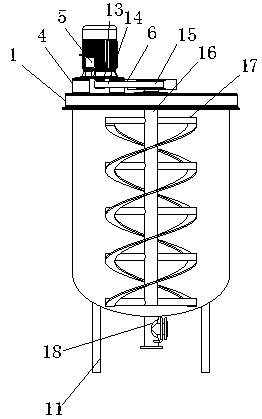

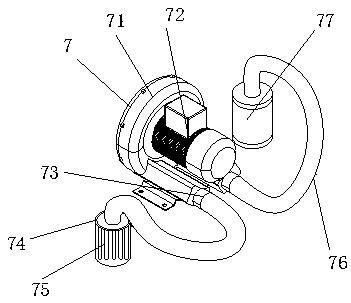

[0028]The present invention provides a kind of enhanced UV printing binding force coating polyester film coating liquid mixing device here through improvement, comprises tank body 1, first feeding pipe 2, second feeding pipe 3, fixed frame 4, the first A motor 5, protective cover 6, feed hopper 8, controller 9, power cord 10, support arm 11, driving pulley 13, belt 14, driven pulley 15, main shaft 16, stirring blade 17, discharge valve 18, circulati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com