A kind of self-assembly of gold nanorods and its preparation method and application

A gold nanorod and self-assembly technology, which is applied in nanotechnology, nanotechnology, metal processing equipment, etc., can solve the problems of cumbersome assembly process and long reaction time, achieve fast switching effect, stable product properties, and wide application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

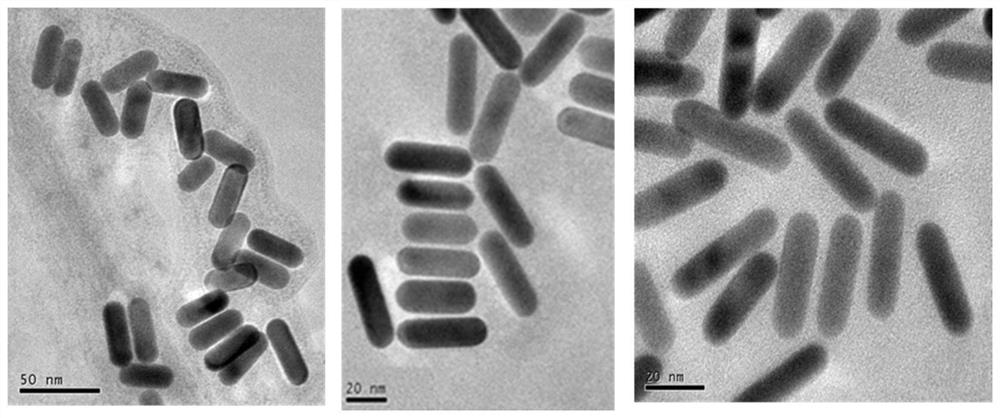

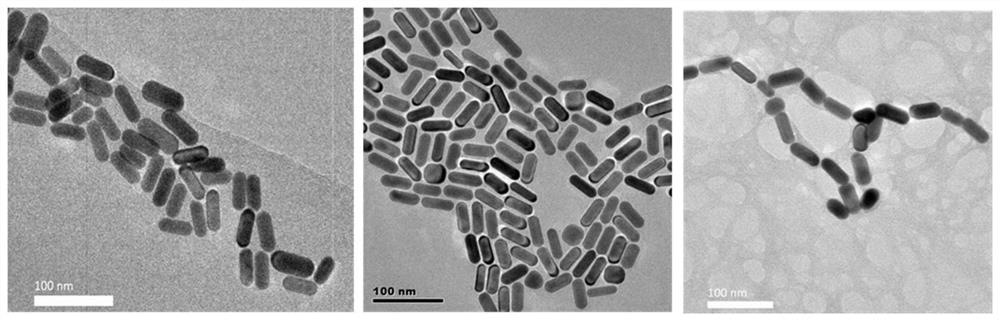

Embodiment 1

[0032] This embodiment provides a self-assembly of gold nanorods in a side-by-side mode, the preparation method of which comprises the following steps:

[0033] (1) Preparation of seed solution: under stirring, 0.25mL of 10mM HAuCl 4 The solution was added to 7.5 mL of 100 mM CTAB solution, followed by a rapid injection of 1.65 mL of deionized water and 0.6 mL of freshly prepared 1 mM NaBH on ice 4 solution, the resulting tan solution was stirred for an additional 1 min and aged at 30 °C for 2 h.

[0034] (2) Preparation of gold nanorod solution: 50 μL of 10 mM AgNO 3 Solution was added to 0.5 mL of 10 mM HAuCl 4Add 0.6 μL of 100 mM ascorbic acid (AA) to 10 mL of 100 mM CTAB mixed solution at 30°C under vigorous stirring (600 rpm) until the color becomes colorless, then quickly inject 12 μL of the seed solution, and the resulting mixed solution is released at 30 C overnight. The obtained Au NRs solution was centrifuged at 10,000 rpm for 10 minutes, and the gold nanorods we...

Embodiment 2

[0037] The present embodiment provides a tail-to-tail mode gold nanorod self-assembly body, and its preparation method comprises the following steps:

[0038] (1) Preparation of seed solution: under stirring, 0.25mL of 10mM HAuCl 4 The solution was added to 7.5 mL of 100 mM CTAB solution, followed by a rapid injection of 1.65 mL of deionized water and 0.6 mL of freshly prepared 1 mM NaBH on ice 4 solution, the resulting tan solution was stirred for an additional 1 min and aged at 30 °C for 2 h.

[0039] (2) Preparation of gold nanorod solution: 50 μL of 10 mMAgNO 3 solution was added to 0.5 mL of 10 mM HAuCl 4 Add 0.6 μL of 100 mM ascorbic acid (AA) to 10 mL of 100 mM CTAB mixed solution at 30°C under vigorous stirring (600 rpm) until the color becomes colorless, then quickly inject 12 μL of the seed solution, and the resulting mixed solution is released at 30 C overnight. The obtained Au NRs solution was centrifuged at 10,000 rpm for 10 minutes, and the gold nanorods were...

Embodiment 3

[0042] This embodiment provides a self-assembly of gold nanorods in a side-by-side mode, the preparation method of which is the same as in Example 1, the difference being that the AgNO 3 The amount of solution added was changed from 50 μL to 60 μL.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com