Asphalt pavement construction method

A technology of asphalt pavement and construction method, applied in the field of asphalt pavement construction, can solve the problems of asphalt becoming viscous, asphalt reuse, affecting repair effect, etc., and achieve the effects of improving stability, reducing usage, and improving repair effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

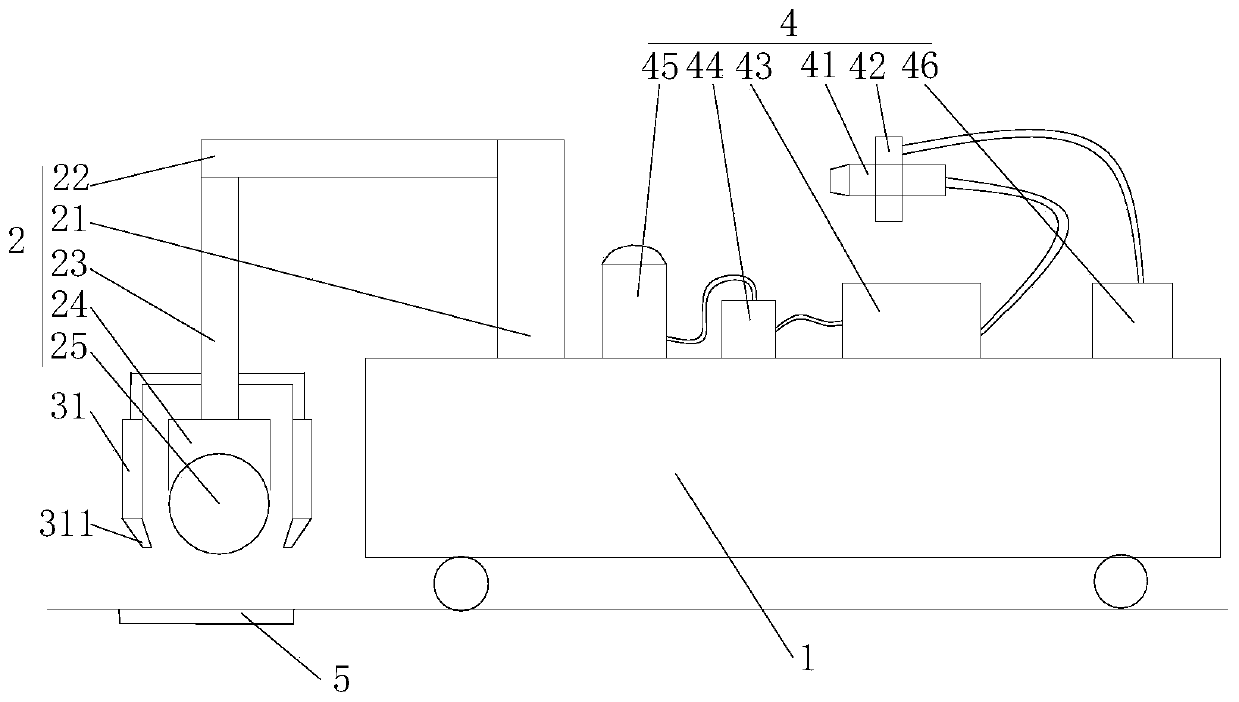

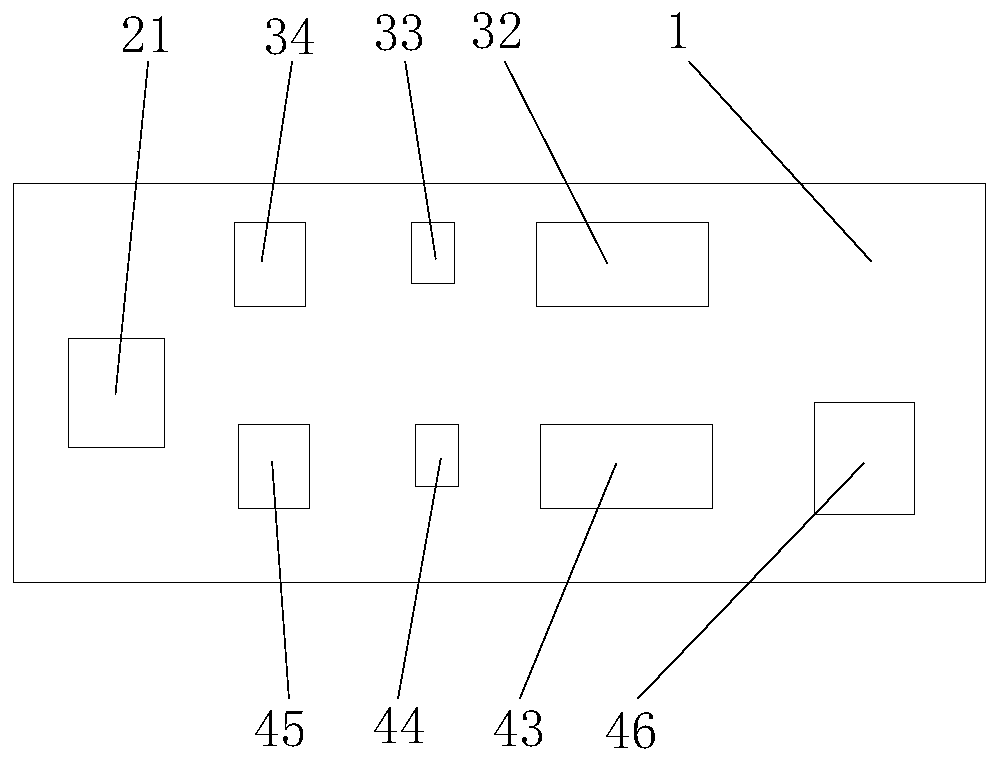

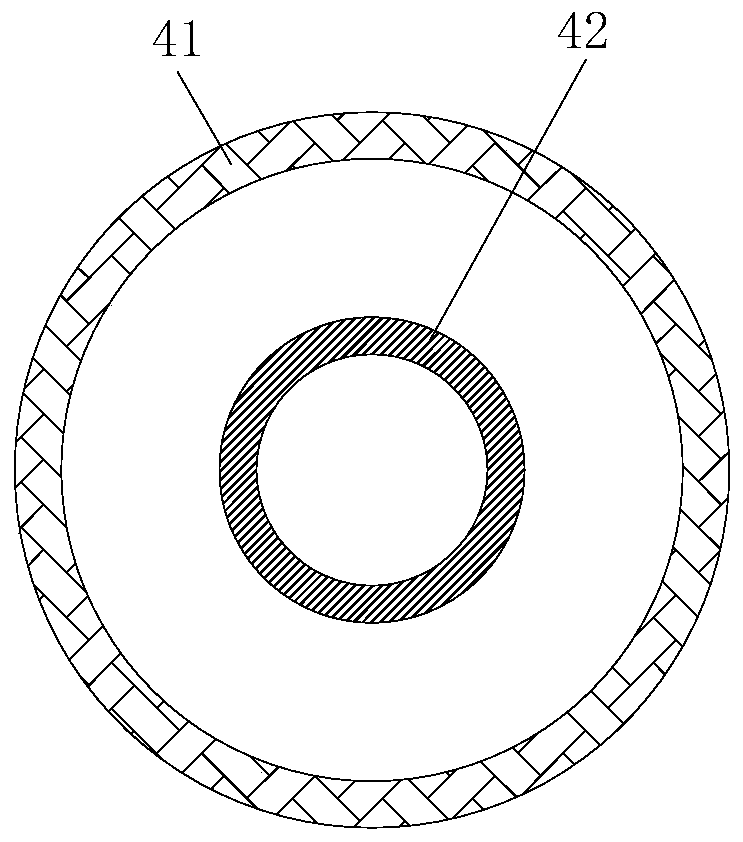

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0028] Such as Figure 1 to Figure 3 As shown, the invention provides a kind of asphalt pavement construction method, comprising:

[0029] Step 1. Clean the gaps in the asphalt pavement to be repaired;

[0030] Step 2. Heating the asphalt pavement to be repaired that has been cleaned in step 1, and then cutting and crushing the gaps on the asphalt pavement to be repaired. While cutting and crushing, add asphalt regeneration agent to the gaps to restore the crushed asphalt to fill the gap;

[0031] Step 3. After the crushing work in step 2 is completed, continue to add asphalt repair agent to the gap, and further fill the gap of the asphalt pavement to be repaired;

[0032] Step 4: After the asphalt repair agent is filled in the gap in step 3, the repaired road surface is r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com