Roller running mechanism

A technology of running mechanism and roller, which is applied in the direction of building structure, door/window accessories, wing leaf parts, etc., can solve the problems of adverse effects on the durability of running performance rollers, permanent deformation of plastic materials, etc., so as to avoid permanent deformation and improve use The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

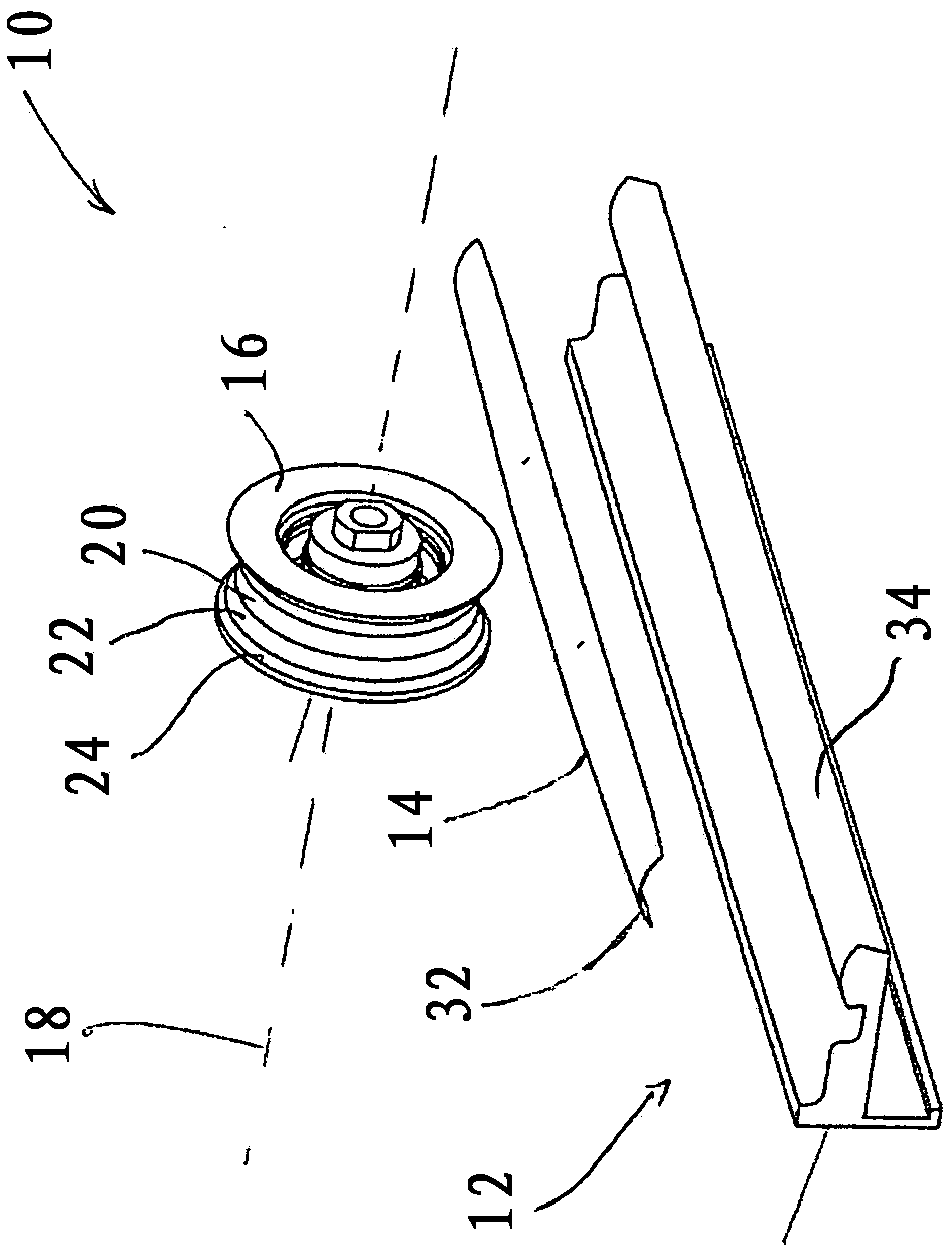

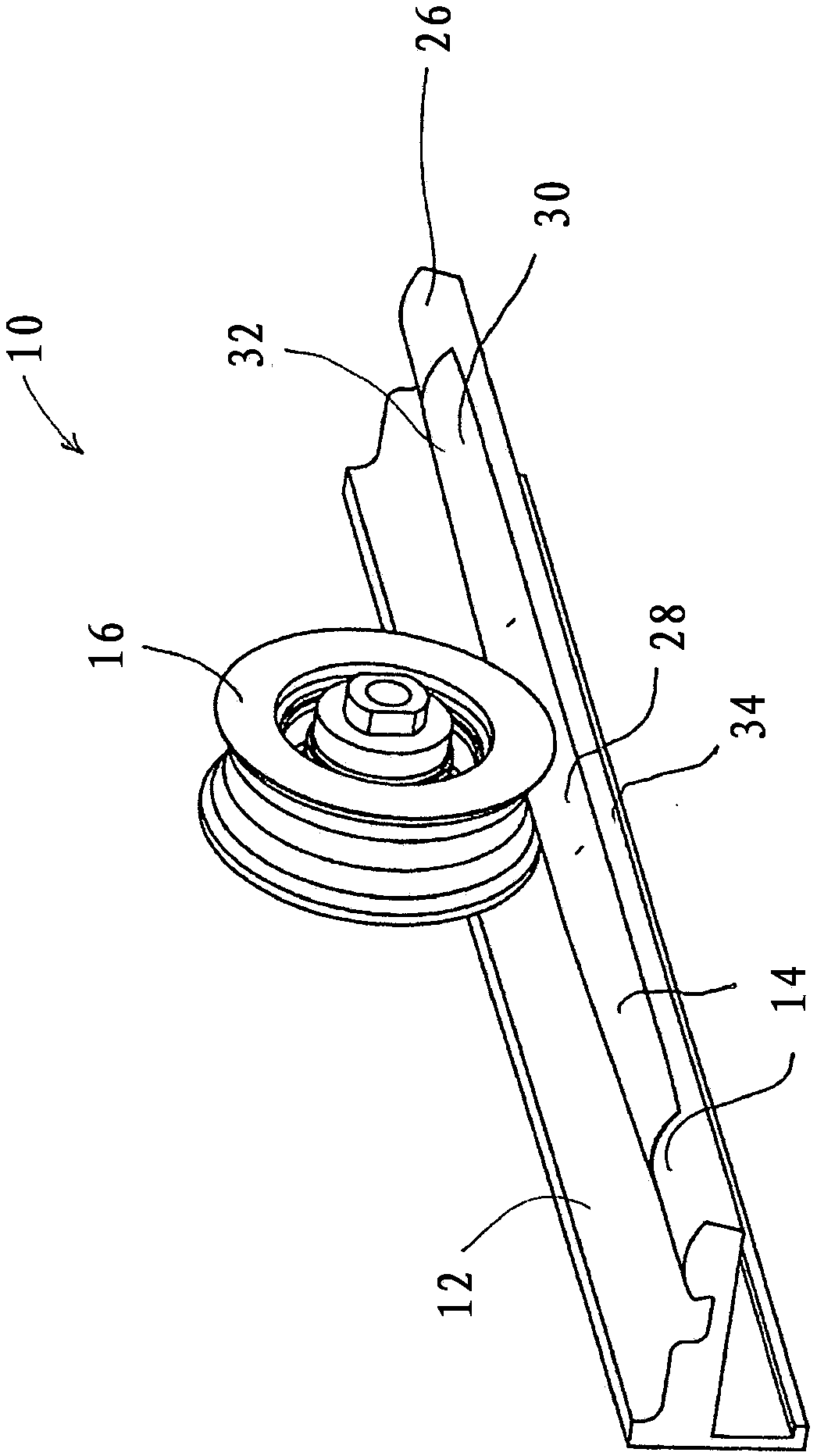

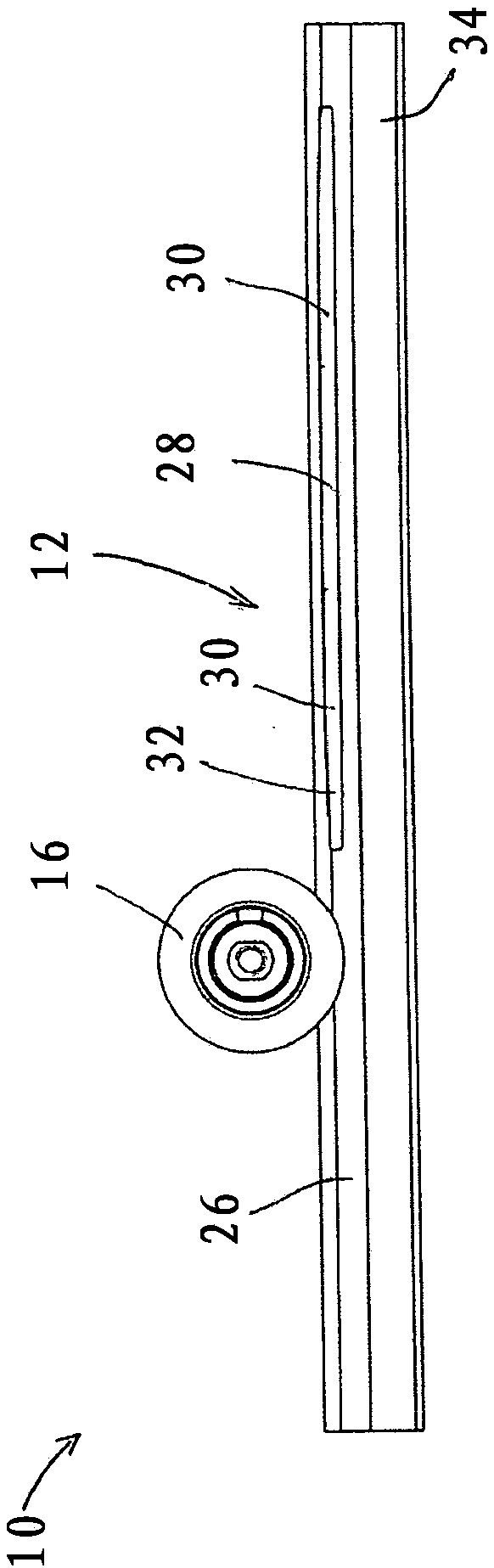

[0038] figure 1 with figure 2 A perspective view of the roller running mechanism 10 according to the invention is shown in an exploded view or in an assembled arrangement. The roller carriage 10 has a carriage 12 and at least one carriage 16 which has a running surface 14 formed thereon and on which the carriage can roll. exist figure 1 with figure 2 Only a part of the operating structure 12 is shown in FIG.

[0039] The roller 16 has at least two roller segments 20 , 22 , 24 of different hardness, which are arranged next to each other along the rolling axis 18 and are designed to be supported on the running surface 14 . The running roller 16 has in particular a roller section 20 which has a relatively low stiffness and is arranged centrally along the rolling axis 18 . The roller segment 20 is arranged between two roller segments 22 of greater hardness. Furthermore, two outer roller sections 24 are provided, between which roller sections 20 and 22 are arranged. The ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com