Anti-pollution fuel tank pressure adjusting device

An adjustment device and anti-pollution technology, which is applied in the direction of oil supply tank device, fluid pressure actuation device, accumulator device, etc., can solve the problem of oil contamination of the oil tank, etc., and achieves easy maintenance, convenient portability, and reduced time costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0019] After the pressurized fuel tank is filled, it is necessary to release air and oil to adjust the pressure of the pressurized fuel tank. The vent hole is set at the highest point of the fuel tank. Contaminate the surface of the fuel tank, especially some sensors, electrical connectors, and valves on the surface of the fuel tank, causing the illusion of oil leakage. In order to solve the problem of air release and oil discharge in the pressurized fuel tank, an anti-pollution fuel tank pressure adjustment device is designed.

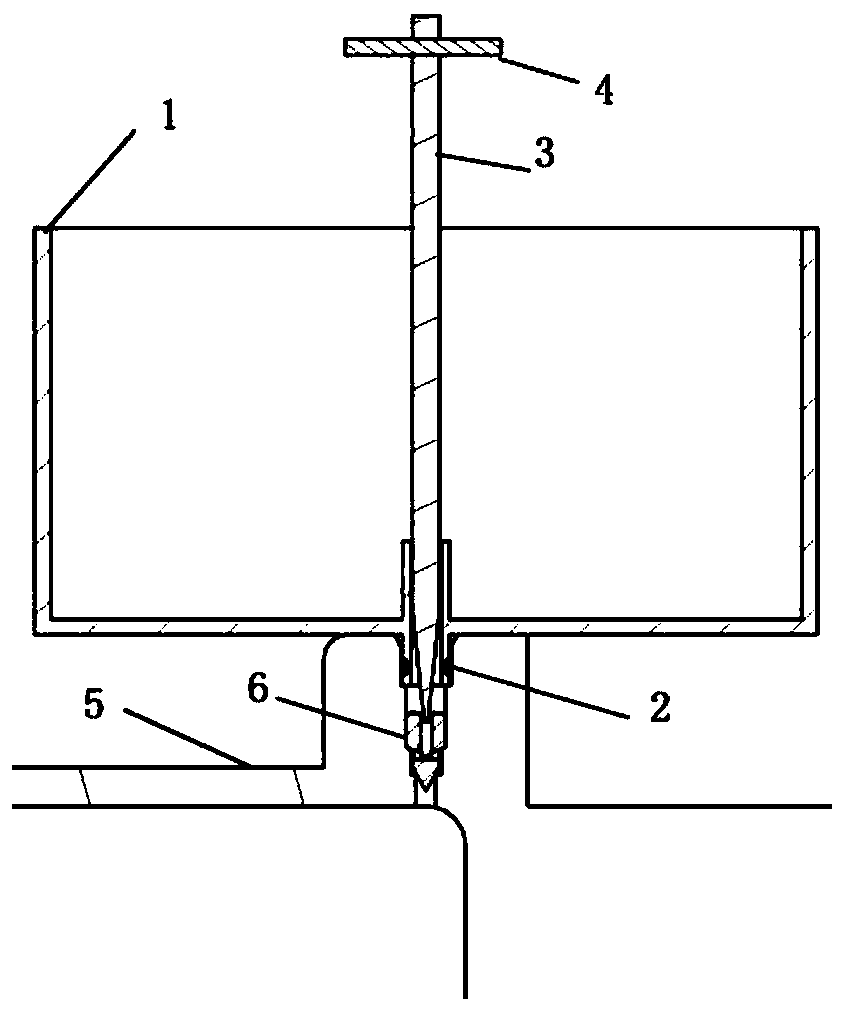

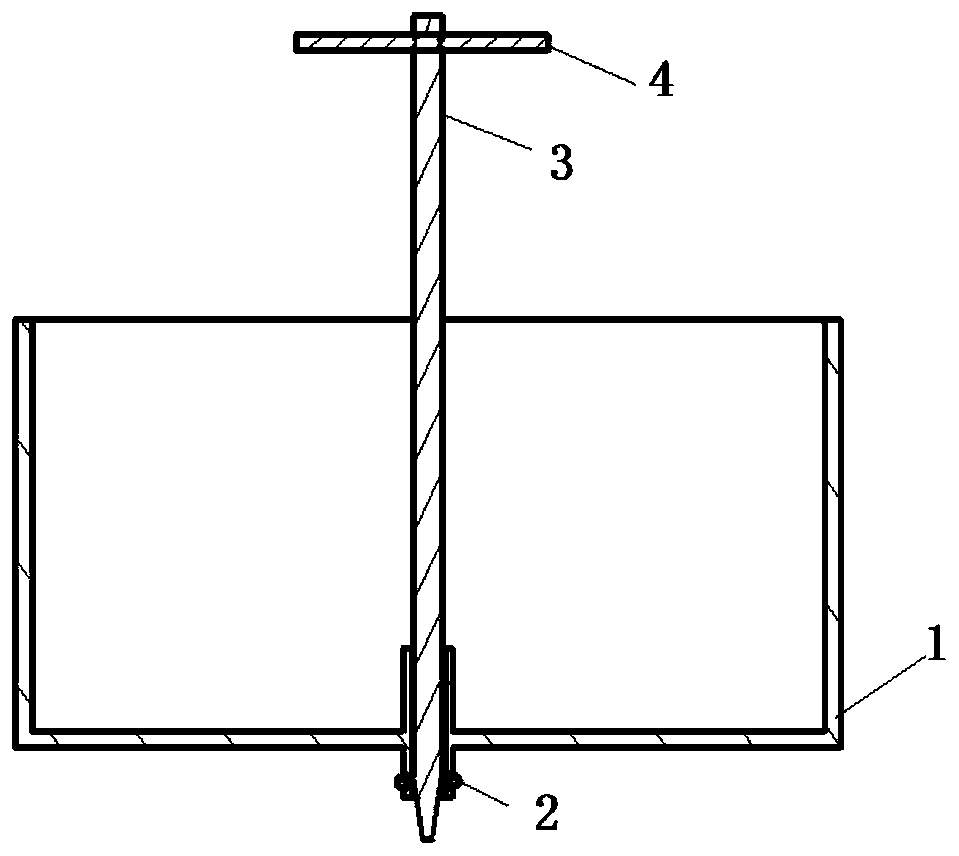

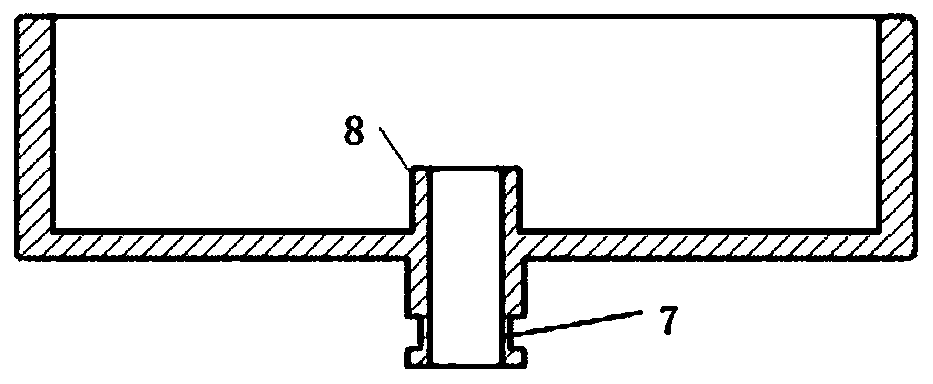

[0020] Such as figure 1 As shown, the oil tank pressure adjustment device includes the oil receiving pan 1, the adjusting rod 3, the force rod 4 and the air release valve 6; the outer circle of the oil receiving pan 1 is designed with a sealing groove 7, and an O-ring is installed on the sealing groove 7 2. The O-ring 2 cooperates with the inner wall of the fuel tank to form a sealing structure to ensure that the air and oil released from the pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com