Energy-saving test bench for multi-stage gear pump

A technology for gear pumps and test benches, applied in the field of test benches, which can solve the problems of inapplicability, rated pressure and flow rate of coupled pumps, and unsatisfactory energy-saving effects, etc., to achieve strong practicability, good power recovery effect, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following is a specific embodiment of the present invention, and the present invention will be further described in conjunction with the accompanying drawings.

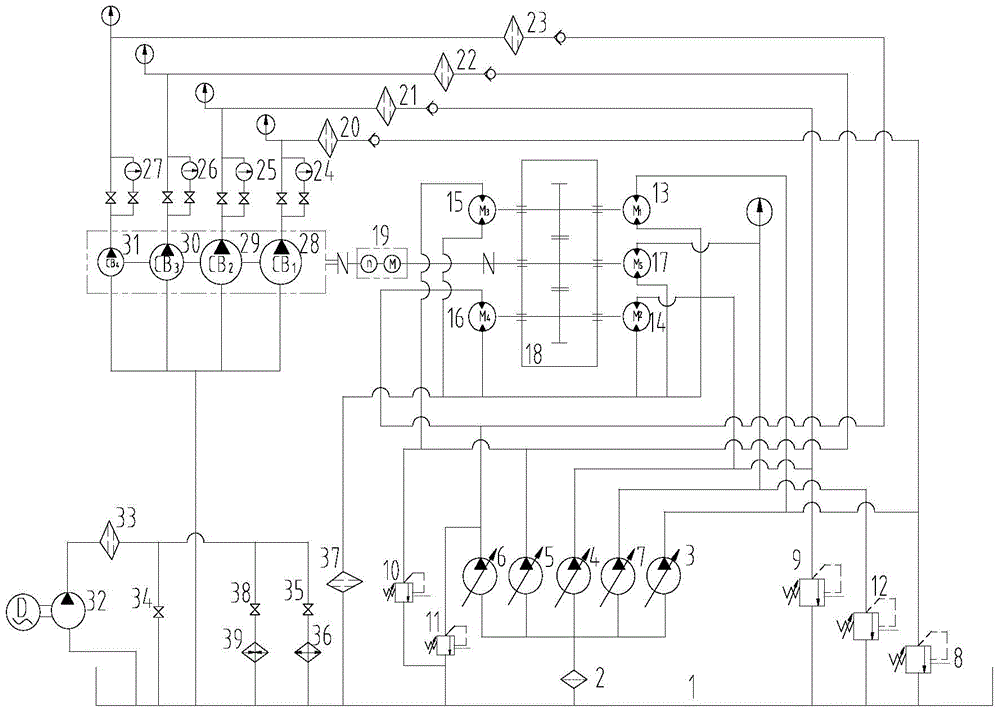

[0025] Such as figure 1 As shown, the multi-connected gear pump energy-saving test bench includes the tested multi-connected gear pump, a loading element, a synchronous gearbox 18, a power compensation element, a detection element, a self-circulating filter cooling device and an oil tank 1. The loading components include I loading hydraulic motor 13 , II loading hydraulic motor 14 , III loading hydraulic motor 15 and IV loading hydraulic motor 16 . Synchronous gearbox 18 is made up of casing, gear, four power input shafts and a power output shaft. The power compensation element includes a mechanical compensation hydraulic motor 17 and five volume compensation pumps 3 , 4 , 5 , 6 , 7 .

[0026] The tested multiple gear pump is a quadruple gear pump composed of I tested pump 28 , II tested pump 29 , III tes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com