Novel margarine production system and process

A margarine and production system technology, applied in the production/processing of edible oil/fat, etc., can solve the problems of neglecting the control of product quality, and achieve the effect of ensuring quality, solving rough process and ensuring cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further explained below in conjunction with specific embodiments.

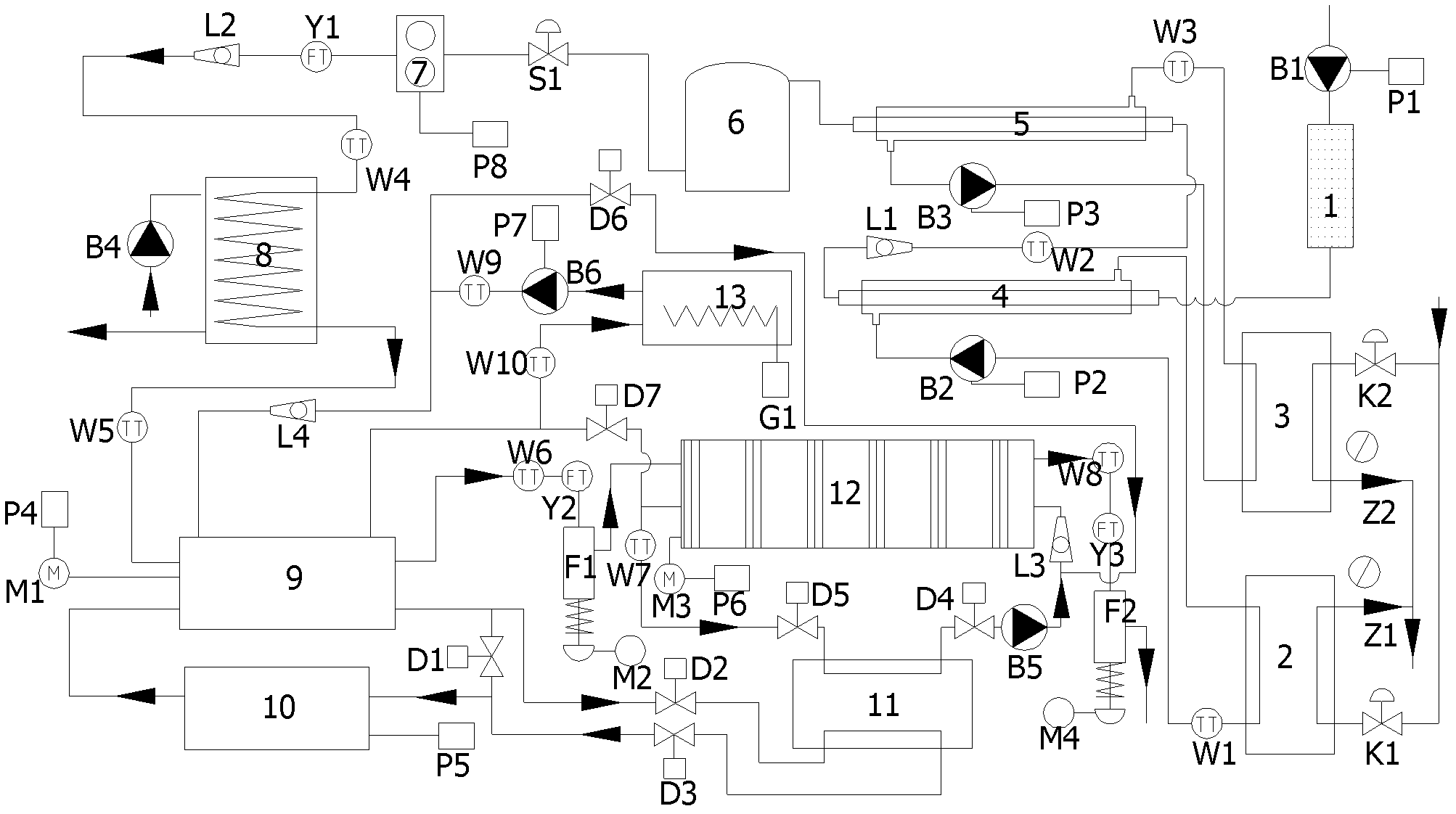

[0035] Such as figure 1 As shown, the new margarine production system of the present invention includes filter sterilization device, pre-cooling device, quenching device, refrigeration supply device, kneading device and hot water supply device:

[0036] The filter sterilization device includes a bag filter 1, a first plate-fin heat exchanger 2, a second plate-fin heat exchanger 3, a first tube-in-tube heat exchanger 4 and a second tube-in-tube heat exchanger 5, The cream transfer pump B1 is connected to the bag filter 1 through the cream output pipeline. The cream transfer pump B1 is equipped with a frequency converter P1 that adjusts the speed of the cream transfer pump B1; the steam input pipeline is respectively opened through the adjustable opening steam valve K1 and adjustable opening The degree of steam valve K2 is connected to the steam input ends of the first plate-fin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com