Cascade bent tail plate with hole groove structure for suction type transonic velocity plane cascade turbine test bed

A transonic and tailgate technology, which is applied in the direction of gas turbine engine testing, machine/structural component testing, mechanical component testing, etc., can solve problems such as no obvious improvement, over-expansion, and increased demand for turbine test benches, and achieve easy The effect of simple implementation and structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

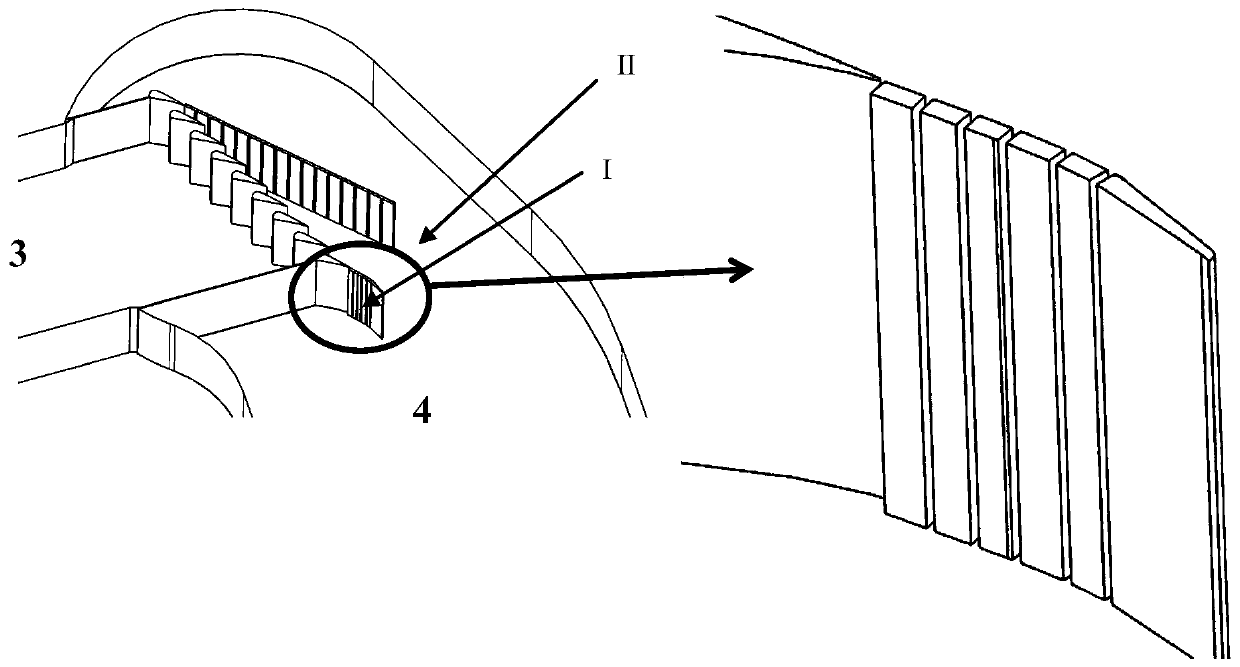

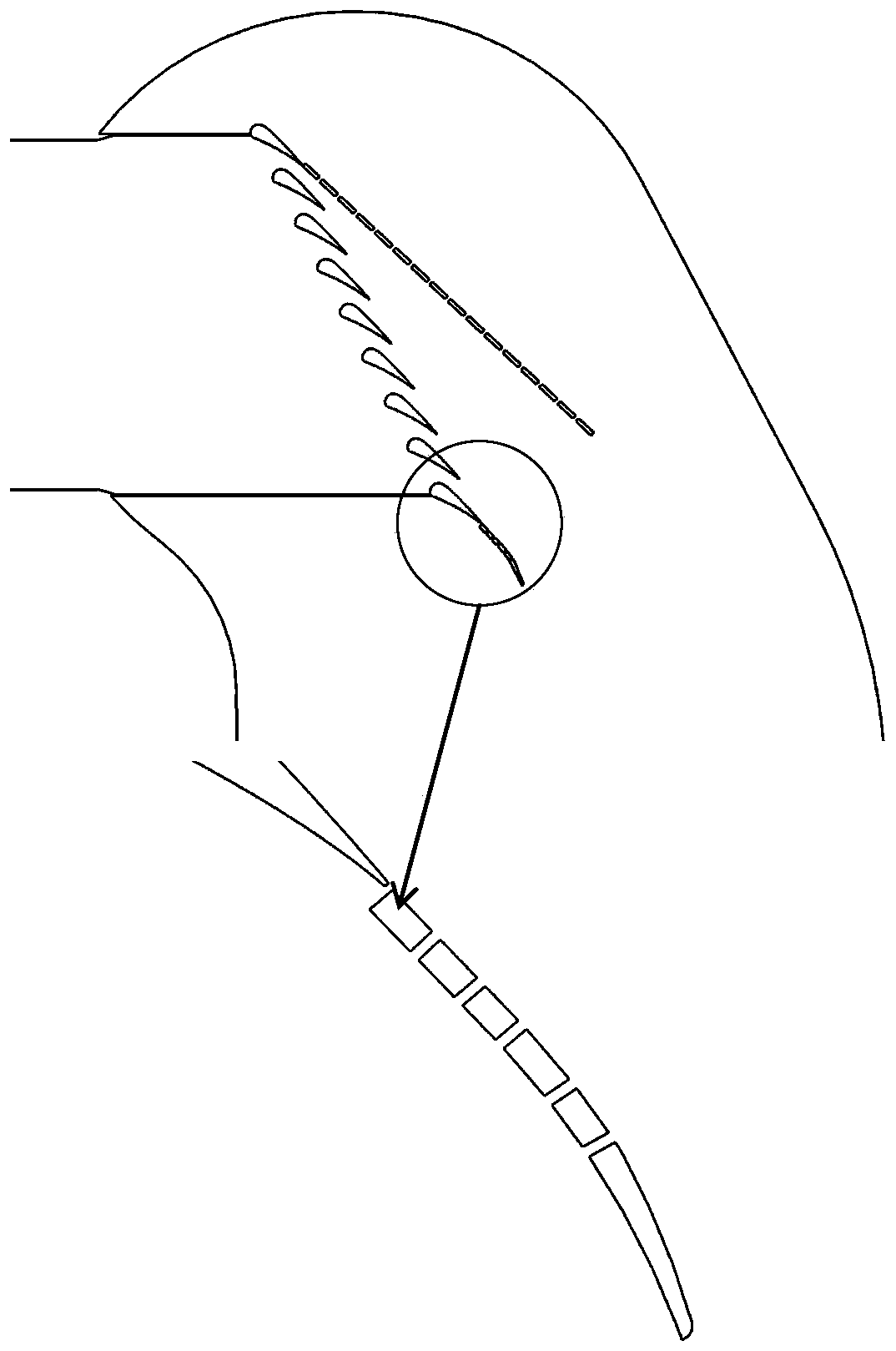

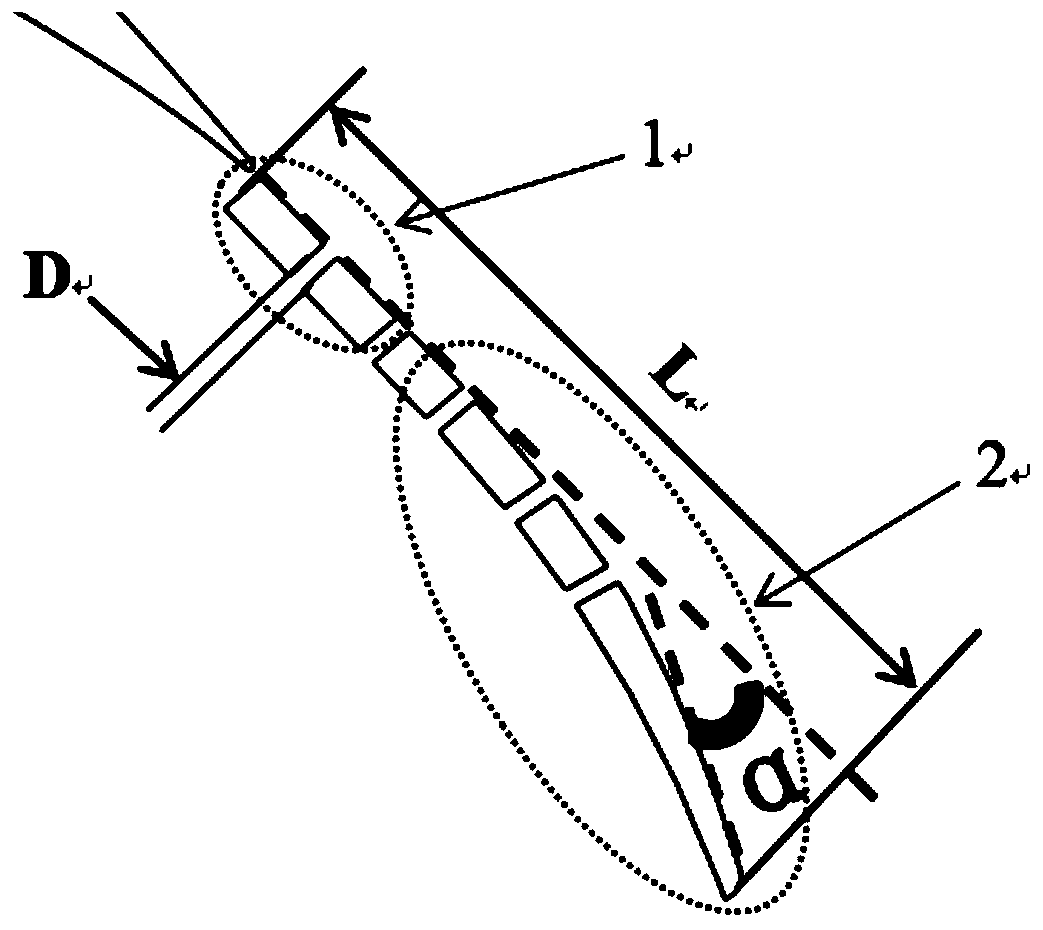

[0025] The invention discloses a suction-type transonic plane blade cascade turbine test stand with a hole-slot structure, and a blade cascade curved tail plate. figure 1 It is a partial three-dimensional schematic diagram of the test section of the suction turbine cascade test bench and the curved tail plate. figure 2 The two-dimensional plan view of the test section of the suction turbine cascade test bench and the curved tail plate, image 3 It is a schematic diagram of the two-dimensional structure of the curved tail plate, Figure 4 It is a schematic diagram of the comparison of the wake pressure contour line between the curved tailgate and the traditional straight tailgate under the conditions of Ma2.0 and -25° attack angle.

[0026] The curved tail plate with a hole-slot structure for improving the wake flow field of the cascade wake of the suction-type transonic plane cascade test bench is composed of an inner curved tail plate and a hole-shaped or groove-shaped holl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com