Lunar-based fidelity coring multistage large-depth drilling system and method

A technology with large depth and fidelity, applied in the field of lunar exploration applications, can solve problems such as increasing the amount of lunar soil coring and sampling, and achieve the effect of increasing the amount of sampling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

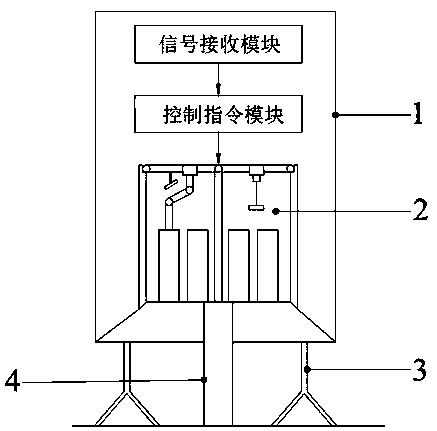

[0039] like figure 1 as shown, figure 1 It is a schematic structural diagram of the log-in device 1 in this embodiment.

[0040] In this embodiment, when the lander 1 lands on the surface of the moon, the lander 1 is supported by the bracket base 3 at the bottom; The coring channel 4 detects; the logger 1 is provided with a signal receiving module and a control instruction module, and the signal receiving module is used to receive the signal sent by the launching base, and convert the signal into a digital control program; In the subsequent digital control program, the control command module outputs control commands to control the moon-based fidelity coring multi-stage deep drilling system 2 inside the logger 1 to work.

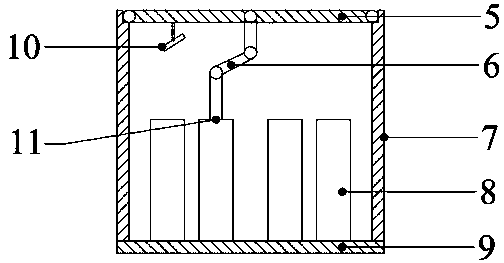

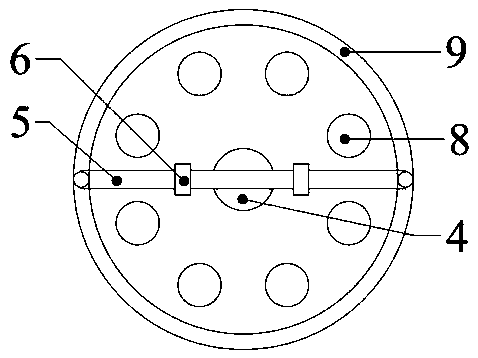

[0041] like figure 2 and image 3 As shown, the lunar-based fidelity coring multi-stage large-depth drilling system 2 provided in this embodiment includes a turntable 9 , fidelity coring tools 8 , a space support 7 , a working platform 5 , a robotic arm ...

Embodiment 2

[0071] This embodiment provides a moon-based fidelity coring multi-stage large-depth drilling method, the method includes the following steps:

[0072] Step 100, when the logger receives the drilling signal sent by the launch base, control the robotic arm to grab the fidelity coring tool from the turntable, and place the fidelity coring tool on the surface of the moon; the details are as described above.

[0073] Step 200, when the robotic arm places the fidelity coring tool on the surface of the moon, obtain the signal output by the hardness sensor, and judge whether the hardness of the soil on the surface of the moon meets the sampling standard according to the signal; specifically as above.

[0074] Step 300, when the hardness of the soil on the lunar surface meets the sampling standard, control the motor drive mechanism in the fidelity coring tool to run, and use the motor drive mechanism to drive an external drilling mechanism to carry out the soil on the lunar surface D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com