Method and device for rapidly obtaining maximum respiration rate of active sludge

A respiration rate and activated sludge technology, which is applied in the field of quickly obtaining the maximum respiration rate of activated sludge, can solve the problems that the system cannot be measured, the error of the electrode system, and the absolute toxicity of water samples cannot be evaluated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

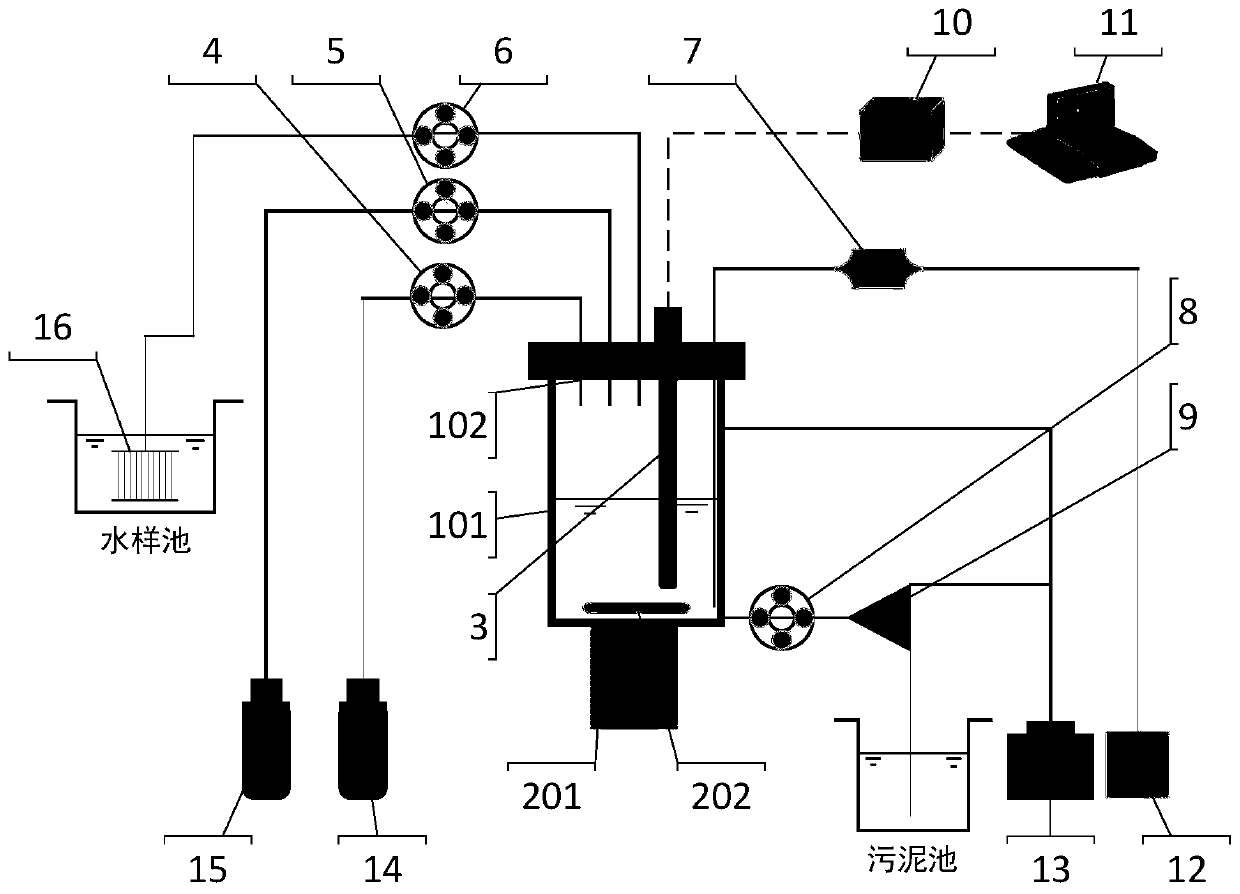

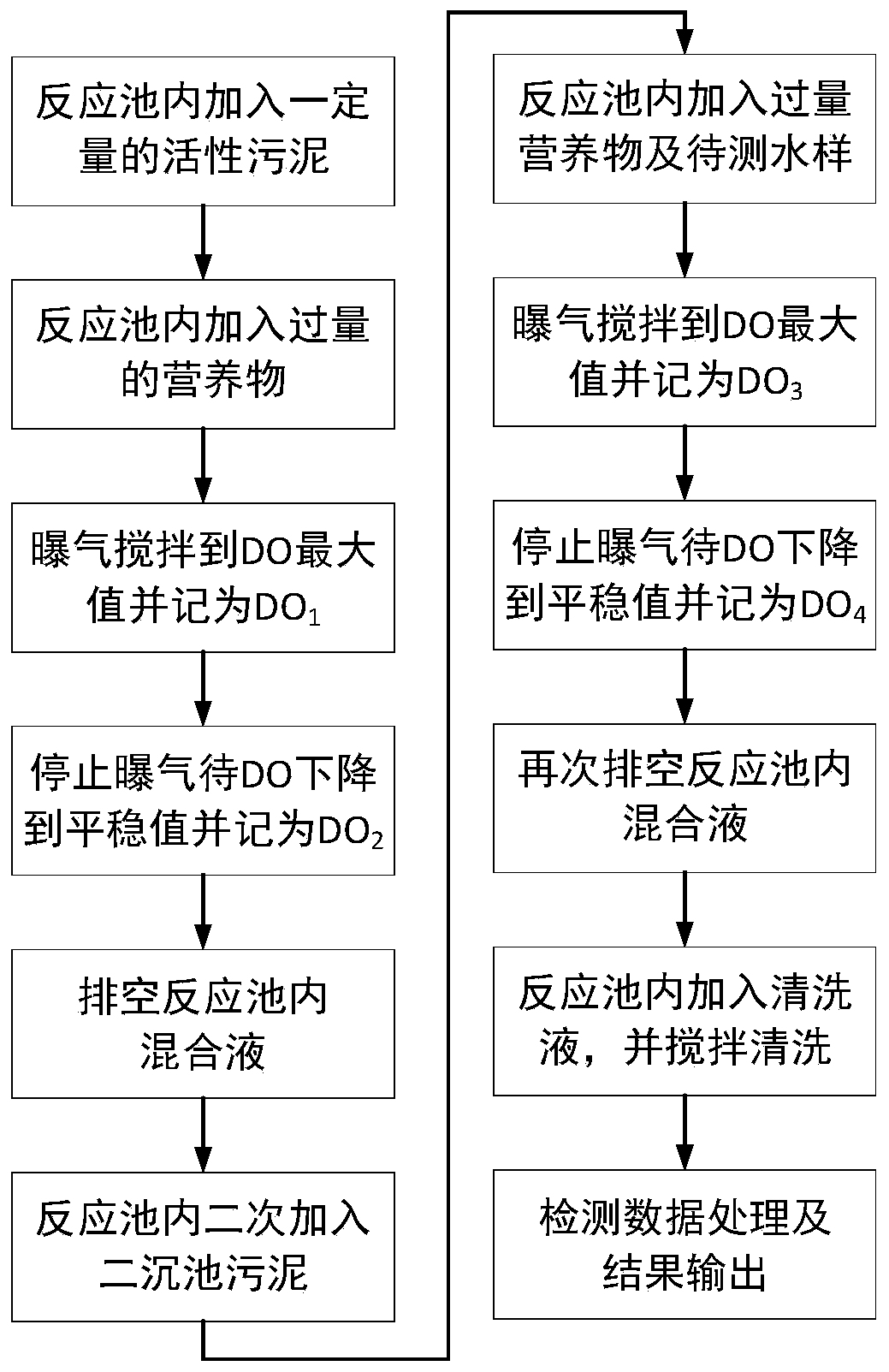

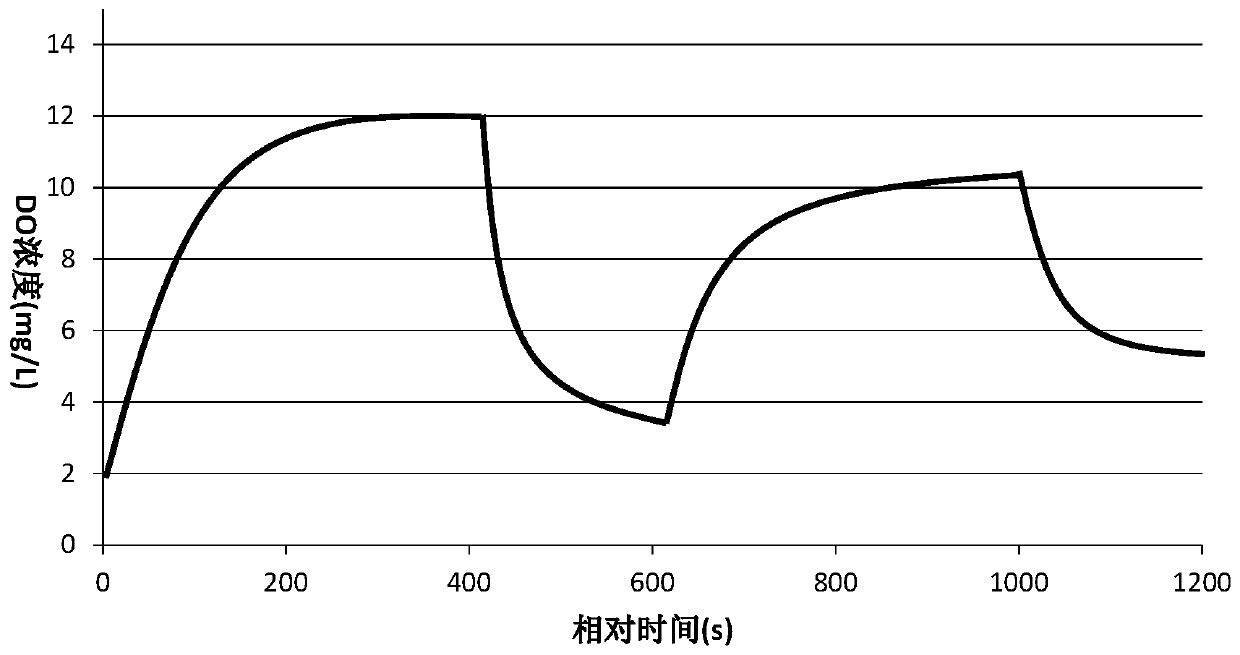

[0032] This example provides a method for measuring the maximum respiration rate OUR of the activated sludge and the toxicity I of the influent water sample by the detection device involved in the present invention. The first step is to start the sludge / empty peristaltic pump 8, switch the three-way solenoid valve 9 to the pipeline where the sludge tank is located, pump about 15mL of sludge into the reaction tank 1, and then start the nutrient solution peristaltic pump 4, Pump about 5mL of nutrient solution into the reaction tank 1, start the magnetic stirring 2 and the micro air pump 7, and collect the signal of the DO electrode 3 at the same time; after about 400 seconds after starting the aeration, record the current dissolved oxygen value as DO 1 , and stop the aeration at the same time, after stopping the aeration for about 200 seconds, record the current dissolved oxygen value as DO 2 ; start the sludge / empty peristaltic pump 8, and switch the three-way solenoid valve 9 ...

Embodiment 2

[0035] A device for measuring the maximum respiration rate of activated sludge in a sewage treatment plant. The detection device includes a reaction tank body 101, a reaction tank cover 102, and a dissolved oxygen DO electrode 3. The reaction tank cover 102 is buckled above the reaction tank 101, and the dissolved oxygen DO electrode 3 Through the reaction tank cover 102 and inserted into the reaction tank 101, the sludge / emptying peristaltic pump 8 is connected to the reaction tank 101 and the three-way solenoid valve 9 through pipelines, and the other two paths of the three-way solenoid valve are connected to the sludge tank and the three-way solenoid valve respectively. Waste liquid tank 13, water sample peristaltic pump 6 is connected with reaction tank 101 and water sample tank through pipeline, micro air pump 7 is connected with reaction tank 101 and air filter 12 through pipeline, nutrient solution peristaltic pump 4, cleaning liquid peristaltic pump 5 are respectively c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com