A kind of pcb plate etching device and using method thereof

A technology for a PCB board and an etching device, applied in the field of PCB board etching devices, can solve the problems of difficulty in adjusting the distance between a spray pipe and a PCB board according to needs, the PCB board cannot achieve the etching effect, and the vibration is strong, so as to avoid the etching effect. The effect of lowering, good shockproof effect and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

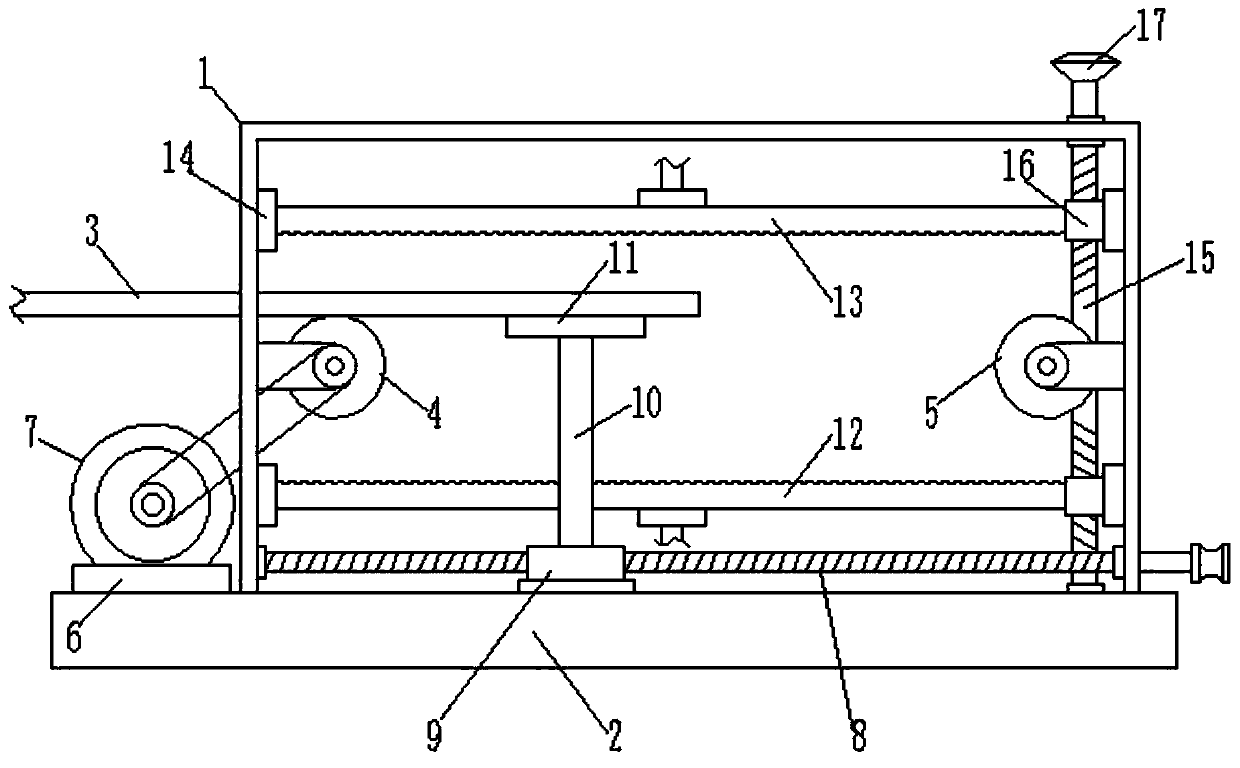

[0032] Such as figure 1 As shown, a PCB board etching device includes a device housing 1 and a shock-absorbing base 2, the left end of the surface of the shock-absorbing base 1 is fixedly welded with a motor holder 6, and a drive motor 7 is fixedly installed on the motor holder 6. The left and right sides of the device housing 1 are provided with openings for the PCB board 3 to enter. The left and right inner walls of the device housing 1 are equipped with a driving wheel 4 and a driven wheel 5, and the rotating shaft of the driving wheel 4 passes through the transmission belt. It is connected with the power output end of the driving motor 7, and the PCB board 3 abuts against the surface of the driving wheel 4 after entering the device housing 1, and the driving motor 7 works to drive the driving wheel 4 to rotate through the belt, thereby driving the PCB board 3 to enter the device housing 1 internal.

[0033] The inner bottom of the device housing 1 is provided with a rotat...

Embodiment 2

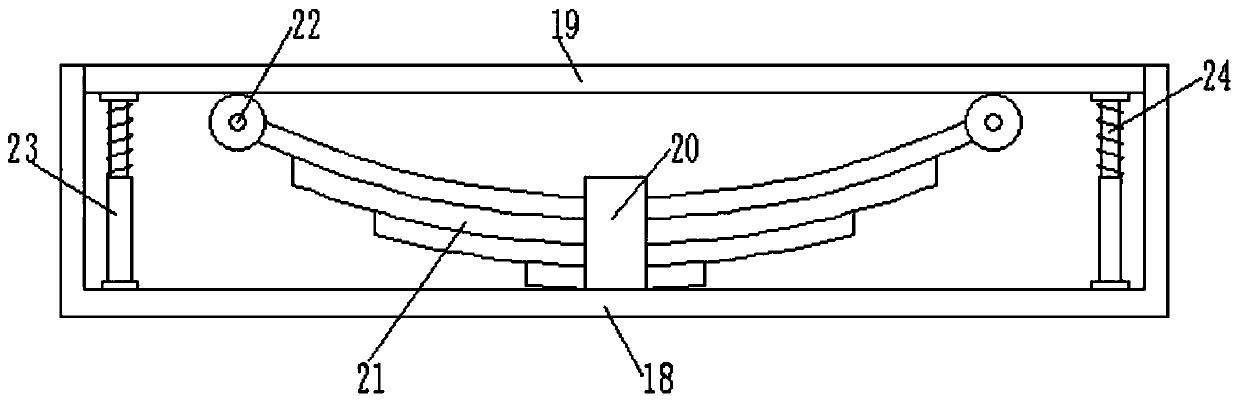

[0042] Such as figure 1 with figure 2 Shown, a kind of PCB board etching device, on the basis of embodiment 1, described shock-absorbing base 2 is made up of fixed frame 18 and anti-vibration mounting plate 19, and anti-vibration mounting plate 19 is slidably connected with described fixed frame 18, And the U-shaped hoop 20 is fixedly installed on the fixed frame 18, and the shock-absorbing steel plate 21 is fixedly installed on the U-shaped hoop 20, and the shock-absorbing roller 22 is installed on the end of the described shock-absorbing steel plate 21. Abutting against the lower surface of the shockproof mounting plate 19, the fixed frame 18 is fixedly installed with a fixed column 23, the fixed column 23 is a hollow cylindrical structure with an open top, and a mounting rod 24 is slidably installed inside the fixed column 23 , the top of the mounting rod 24 is fixedly connected with the described shock-proof mounting plate 19, the described mounting rod 24 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com