Short-fiber rove and filament positioning collector for composite yarn spinning and application thereof

A composite yarn and collector technology, applied in spinning machines, textiles and papermaking, drafting equipment, etc., can solve the problems of difficult to accurately control the yarn structure model, production cost consumption, excessive hairiness, etc., to improve the yarn quality. Yarn performance, high work efficiency, hairiness reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

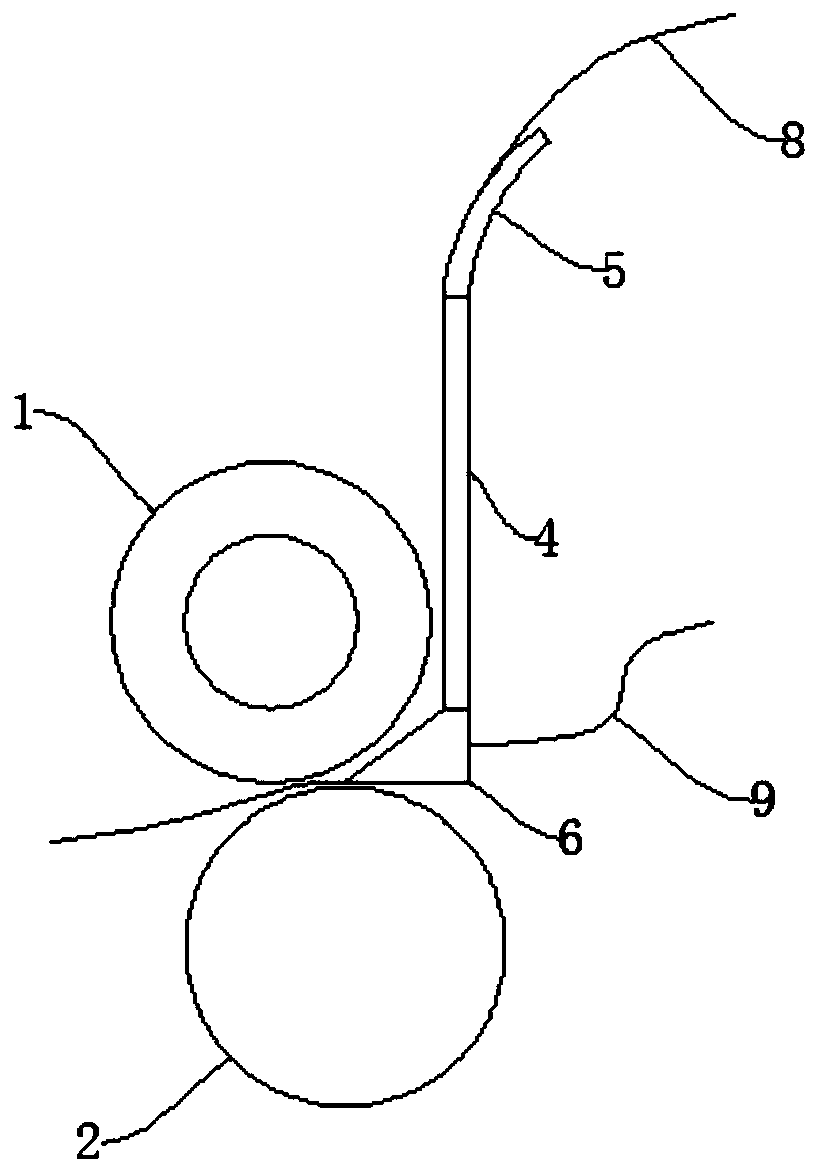

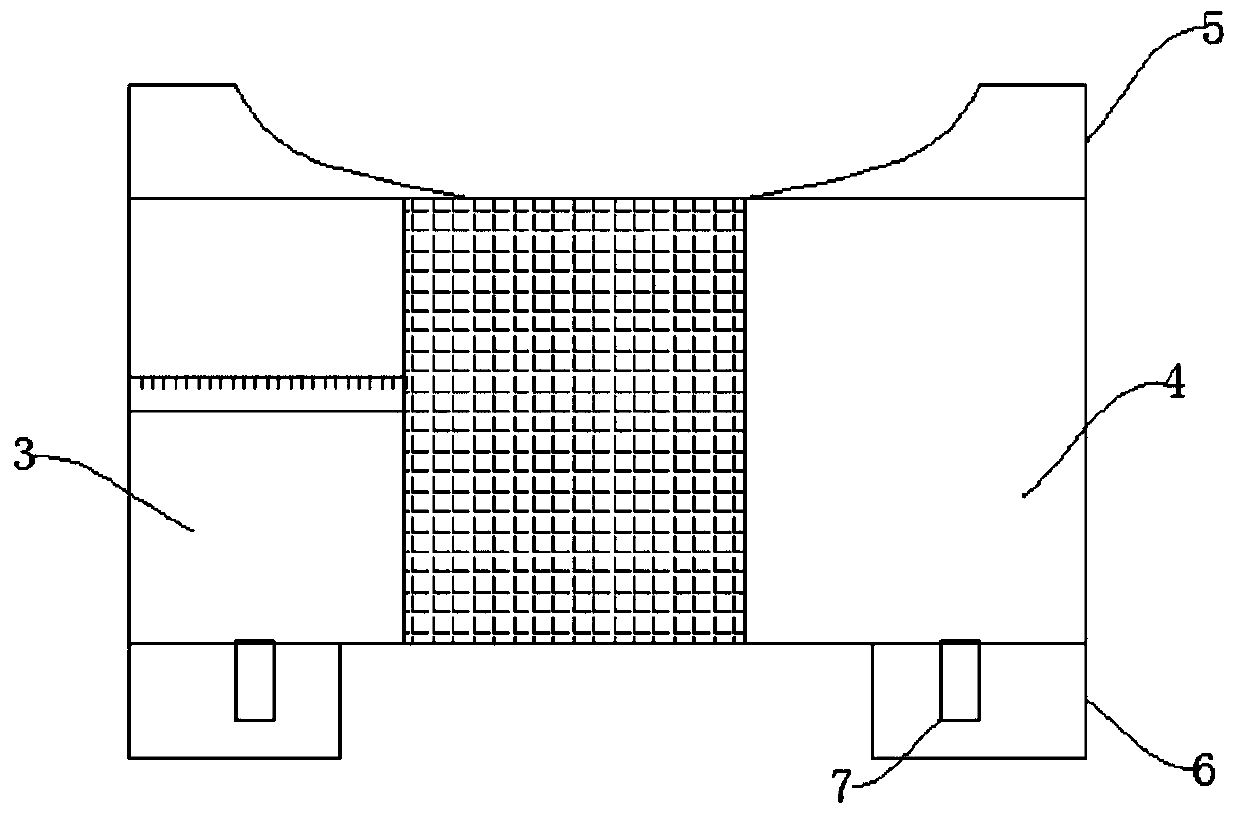

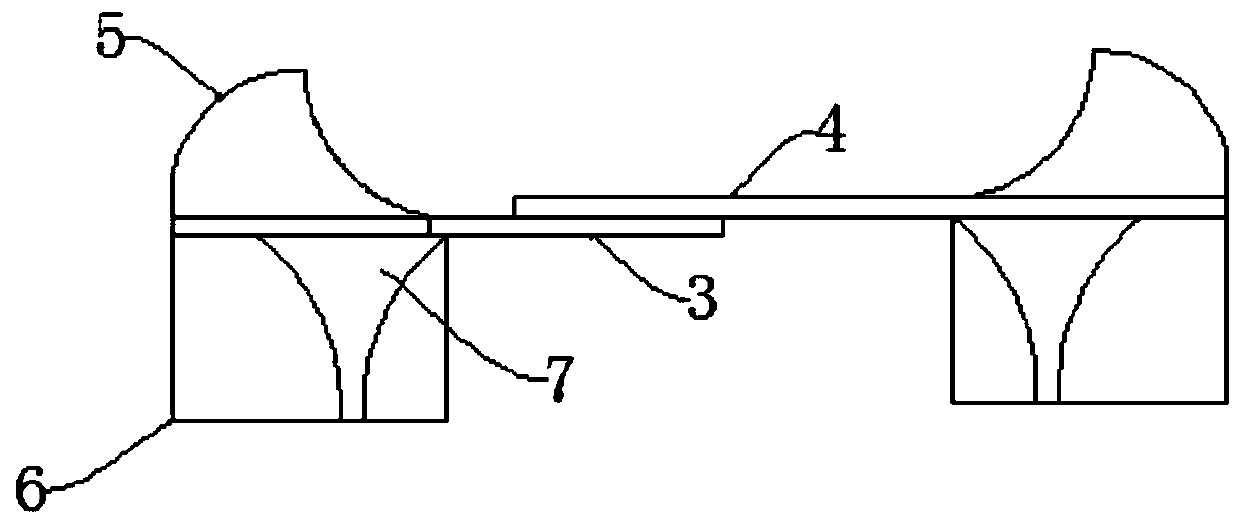

Embodiment 1

[0037] The core-spun composite yarn is spun by using polyester spun rovings with a basis weight of 300tex and polyester filaments with a basis weight of 125dtex. The core-spun yarn of 21tex is spun on the JWFA1520 type spinning frame. The specific process parameters are as follows: roving basis weight 300tex; spun yarn basis weight 21tex; spindle speed 8000r / min; draft ratio 14.3; top roller 3 speed 14.3m / min; The polyester filament 8 passes through the arc surface of the protection block 5, and is sent into the accumulation groove 7 on the triangular stable block 6 along the surface of the counterweight plate, and the staple fiber roving 9 fed into the jaw line passes through the same accumulation process as the filament 8. Slot 7. The two-dimensional two-way bell mouth in the collecting groove 7 plays a whole bundle effect on the roving strands, and the polyester filament 8 passes through the top narrow opening of the same collecting groove 9, effectively positioning the po...

Embodiment 2

[0040] Siro-spun composite yarns were spun by using cotton staple rovings with a basis weight of 5.20g / 10m and polyester filaments with a basis weight of 2.44tex / 12f. The filament 8 is precisely positioned, and the feeding position of the filament 8 is adjusted by selecting the gathering groove 9 where the filament 8 penetrates and the gathering groove 9 where the cotton roving 8 penetrates, and the winding structure of the Siro spinning is adjusted. The specific spinning process is: spun weight 55.8tex; draft ratio 10.7; spindle speed 8000r / min; top roller 3 speed 14.3m / min; twist coefficient 380. The polyester filament 8 passes through the arc surface of the protection block 5, and is sent into the accumulation groove 7 on the triangular stability block 6 along the surface of the counterweight block, and at the same time, the staple fiber roving 9 fed into the jaw line passes through and accumulates with the filament 8. The grooves 7 are separated by 7 mm from the collecting...

Embodiment 3

[0043] The positioning and accumulating device for the filament 8 and the spun roving 9 will also be applicable to various composite spinning methods such as sirofil spinning and embedded composite spinning.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com