Air-leakage-proof dry-blowing casing device and method

A leak-proof, casing technology, applied in the direction of drying gas arrangement, drying, dryer, etc., can solve the problems of easy falling off, easy to swing up and down, damage to casing, etc., to achieve uniform dry blowing effect, avoid wrinkles, increase The effect of lubricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

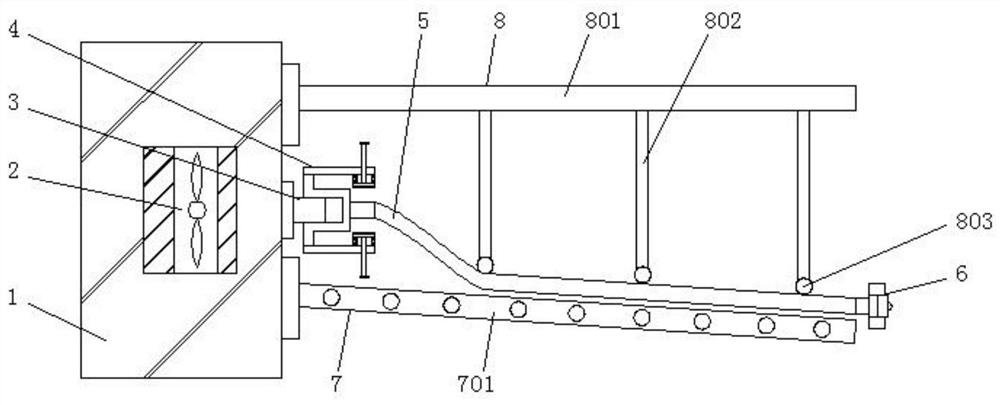

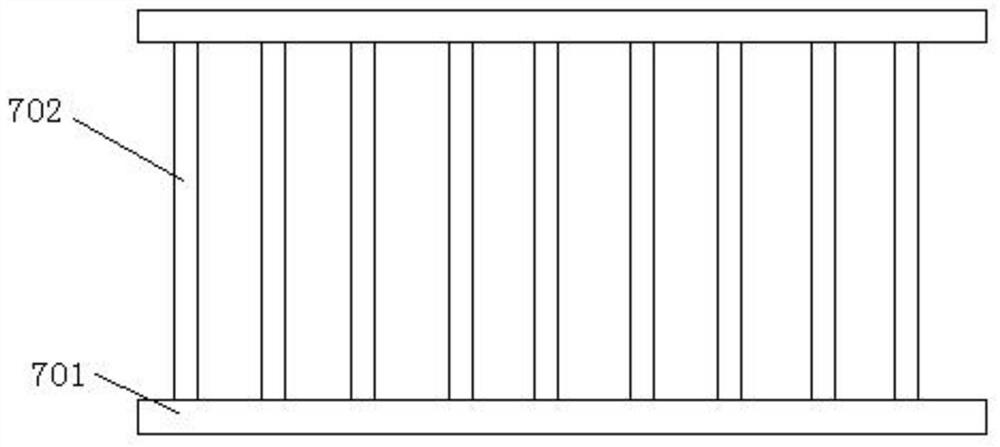

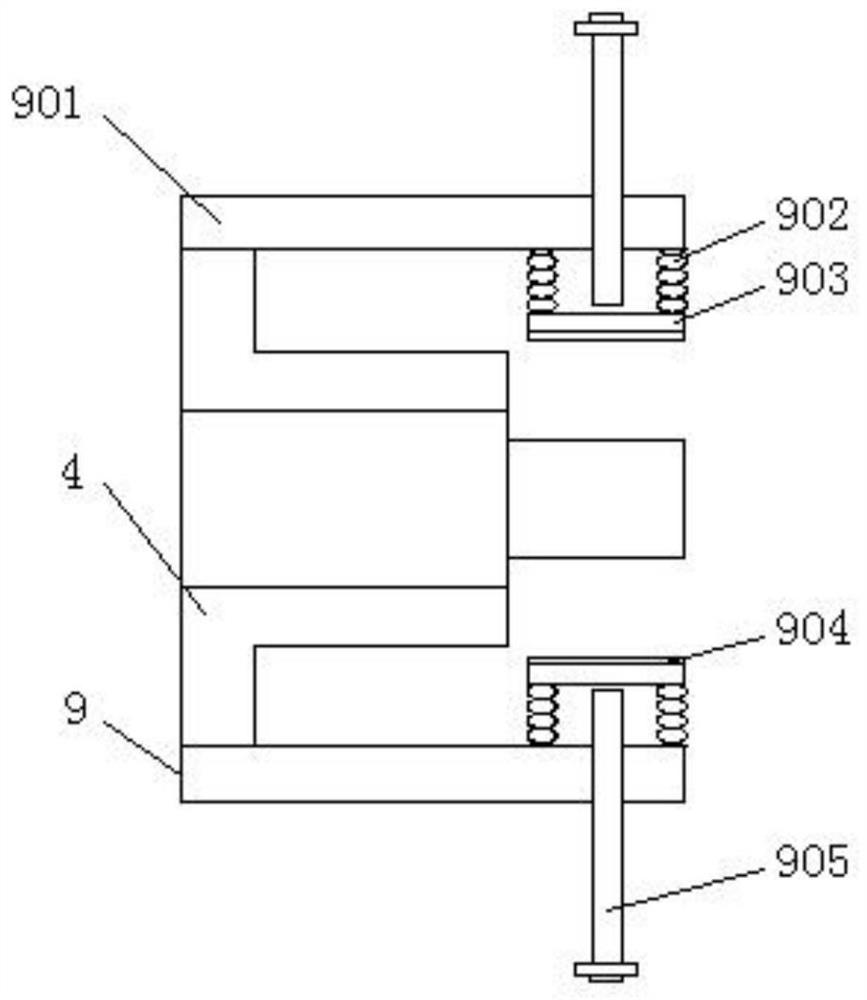

[0044] see Figure 1-4 , a leak-proof dry-blowing casing device and method, comprising a main box 1, a support mechanism 7 and a sealing mechanism 9, a fan 2 is arranged inside the main box 1, and an air outlet 3 is arranged on one side of the main box 1, One side of the air outlet 3 is inlaid with a connecting terminal 4, and one end of the connecting terminal 4 is connected with a casing 5, and one end of the casing 5 is installed with a gas-blocking terminal 6, and the inside of the gas-blocking terminal 6 is provided with an air outlet channel 601 , a sealing plug 602 is placed on one side of the air outlet channel 601, the support mechanism 7 is fixed on the upper end of one side of the main box 1, and the other upper end of the main box 1 is inlaid with a compression mechanism 8, and the sealing mechanism 9 is connected to the connecting end Outer side of head 4.

[0045] see figure 1 and 4 , the sealing plug 602 is flexibly connected to the air-blocking terminal 6, a...

Embodiment 2

[0050] Casing 5 carding: First, separate the entangled casings 5 from each other, and untie the single knotted or adhered casings 5, then pick up one end of the casing 5 and shake it to keep the casing 5 vertical down.

[0051] The steps of casing 5 sealing connection are:

[0052] Step 1. Soak the inlet end and the outlet end of the casing 5 in hot water for ten minutes;

[0053] Step 2: After the inlet end and outlet end of the casing 5 are softened, insert the outlet end of the connection end 4 into the inlet end of the casing 5, and rotate the upper and lower threaded rods 905 at the same time. 903 forms extrusion until the sealing ring 904 presses the casing 5 against the outer wall of the outlet end of the connecting terminal 4 , and then inserts the connecting terminal 4 into the air outlet 3 .

[0054] Step 3: Insert the inlet end of the gas blocking terminal 6 into the outlet end of the casing 5 , and insert the sealing plug 602 into the gas outlet channel 601 in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com