Bagged low-salt bean paste and production and processing method thereof

A processing method and technology for salted beans, which are applied in the field of bagged low-salt watercress and its production and processing, can solve problems such as spoilage, influence on storage time, cardiovascular hypertension, etc. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

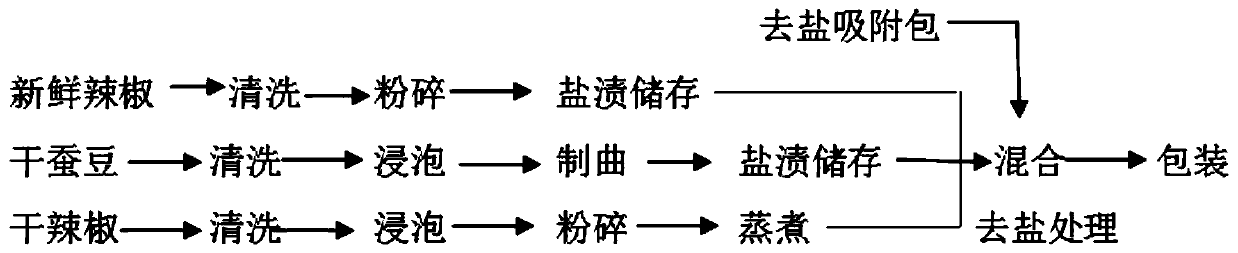

[0048] see figure 1 , a bagged low-salt watercress and a production and processing method thereof, comprising the following ingredients according to weight percentage: 35% of fresh pepper, 25% of dried broad bean, 35% of dried pepper, 0.04% of potassium sorbate, 2.5% of orange peel, 15% of flour %, garlic cloves 1.5%, its production and processing method comprises the following steps:

[0049] S1. Cleaning, crushing and salting the fresh peppers for storage to obtain salted fresh peppers;

[0050] S2. Washing and soaking the dried broad beans, and then performing koji-making treatment on the soaked dried silkworms and flour, and then salting and storing to obtain sweet petals;

[0051] S3. Washing, soaking, pulverizing and steaming dried chili after purchasing to make unsalted rehydrated chili;

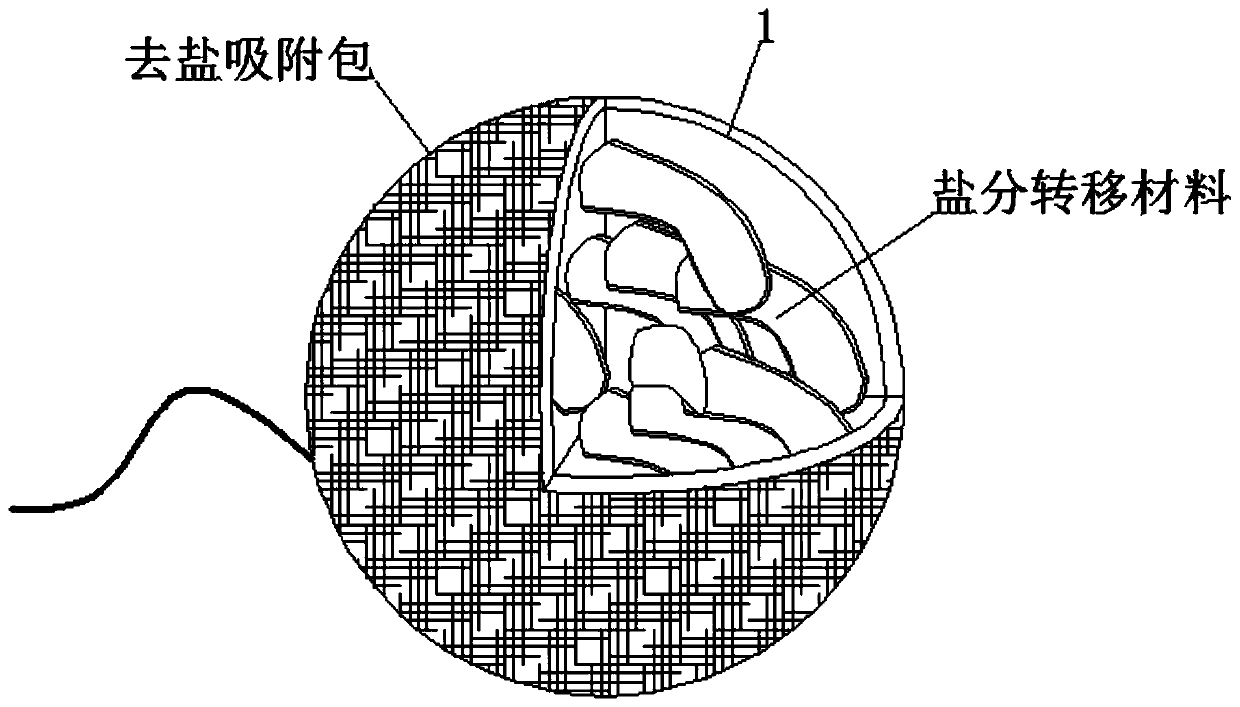

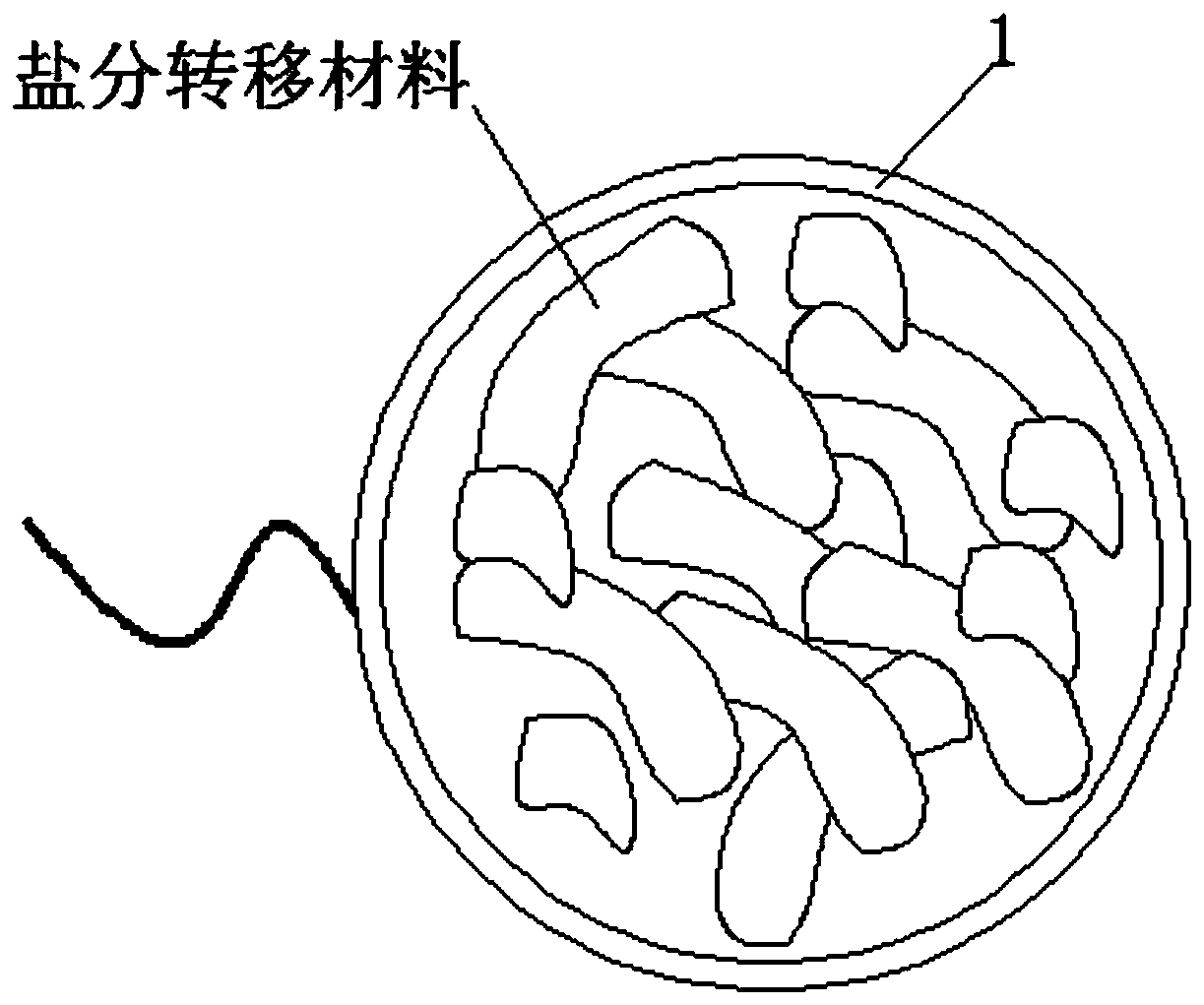

[0052] S4. Please refer to Image 6 , desalting treatment, evenly mixing salted fresh peppers, unsalted rehydrated peppers and sweet petals to obtain semi-finished watercress food,...

Embodiment 2

[0057] see figure 1 , a bagged low-salt watercress and a production and processing method thereof, comprising the following ingredients according to weight percentage: 30% of fresh pepper, 20% of dried broad bean, 30% of dried pepper, 0.03% of potassium sorbate, 2% of orange peel, and 10% of flour %, cloves of garlic 1%, its production and processing method comprises the following steps:

[0058] S1. Cleaning, crushing and salting the fresh peppers for storage to obtain salted fresh peppers;

[0059] S2. Washing and soaking the dried broad beans, and then performing koji-making treatment on the soaked dried silkworms and flour, and then salting and storing to obtain sweet petals;

[0060] S3. Washing, soaking, pulverizing and steaming dried chili after purchasing to make unsalted rehydrated chili;

[0061] S4. Please refer to Image 6 , desalting treatment, evenly mixing salted fresh peppers, unsalted rehydrated peppers and sweet petals to obtain semi-finished watercress fo...

Embodiment 3

[0066] see figure 1 A bagged low-salt watercress and a production and processing method thereof, comprising the following ingredients according to percentage by weight: fresh pepper 40%, dried broad beans 30%, dried chili 40%, potassium sorbate 0.05%, orange peel 3%, flour 20% %, garlic cloves 2%, its production and processing method comprises the following steps:

[0067] S1. Cleaning, crushing and salting the fresh peppers for storage to obtain salted fresh peppers;

[0068] S2. Washing and soaking the dried broad beans, and then performing koji-making treatment on the soaked dried silkworms and flour, and then salting and storing to obtain sweet petals;

[0069] S3. Washing, soaking, pulverizing and steaming dried chili after purchasing to make unsalted rehydrated chili;

[0070] S4. Please refer to Image 6 , desalting treatment, evenly mixing salted fresh peppers, unsalted rehydrated peppers and sweet petals to obtain semi-finished watercress food, then adding desaltin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com