Bolt retention structure integrally formed with artificial crown and manufacturing method of matching bolt channel

A manufacturing method and technology of artificial crowns, which are applied in the direction of fasteners, etc., can solve problems such as high operating process requirements, complicated manufacturing processes, and complicated manufacturing steps, and achieve the effects of simplified processing technology, comfortable wearing, and good retention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The manufacturing method of the plug retaining structure integrally formed with the artificial crown and the matching plug channel includes the following steps:

[0039] (1) collecting three-dimensional spatial information of the patient's teeth;

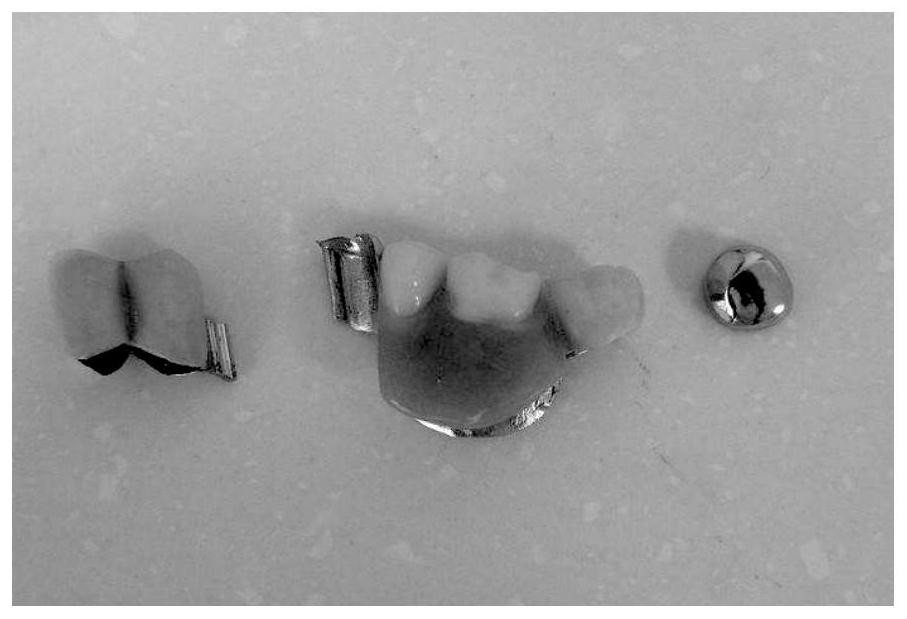

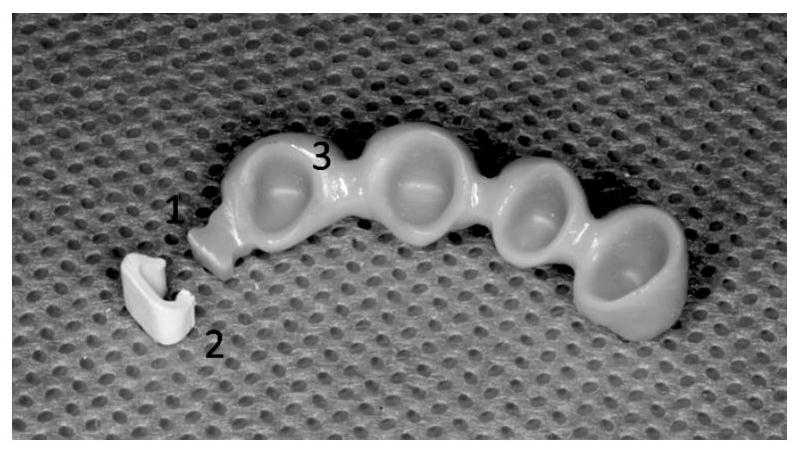

[0040] Clinically collect the patient's dentition impression, turn over the plaster model, and then scan the plaster model to collect the three-dimensional space data of the teeth. The results are shown in Figure 4 . Three-dimensional space data of teeth were collected by Sirona scanner inEos X5 and scanning software Sirona inLabSW16.

[0041] (2) According to the tooth three-dimensional space information collected in step (1), an artificial crown with a plug retention structure is designed; professional dental design software is used for design. The design software is from exocad GmbH in Germany dental2.2Valletta dental design software.

[0042] (3) The artificial dental crown with plug retention structure designed in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com