Disinfection device for sanitary napkin production

A disinfection device and technology for sanitary napkins, applied in the field of sanitary napkin production, can solve the problems of inability to completely kill microorganisms, product quality problems, incomplete disinfection, etc., and achieve good disinfection effect, high work efficiency, and completely kill microorganisms. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

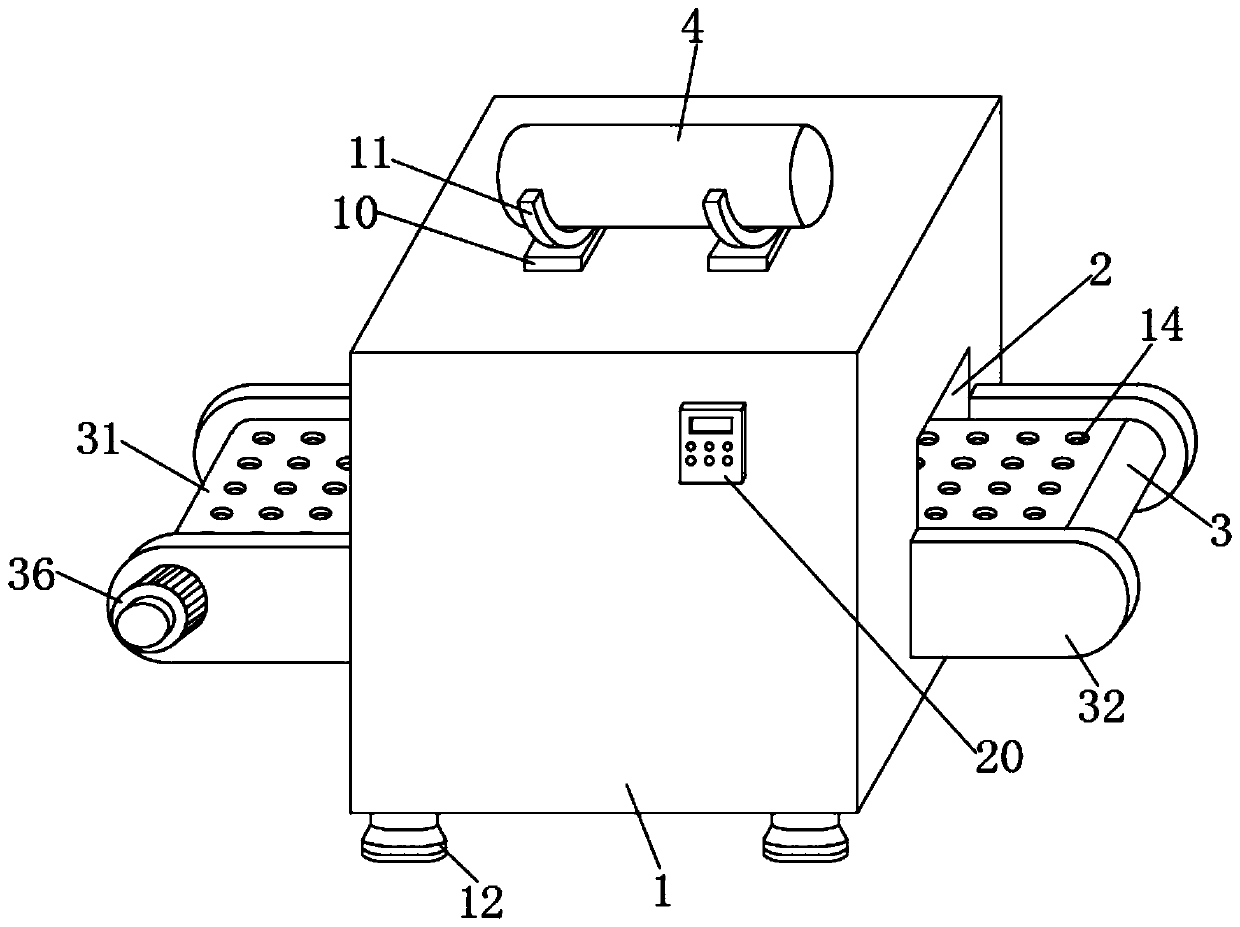

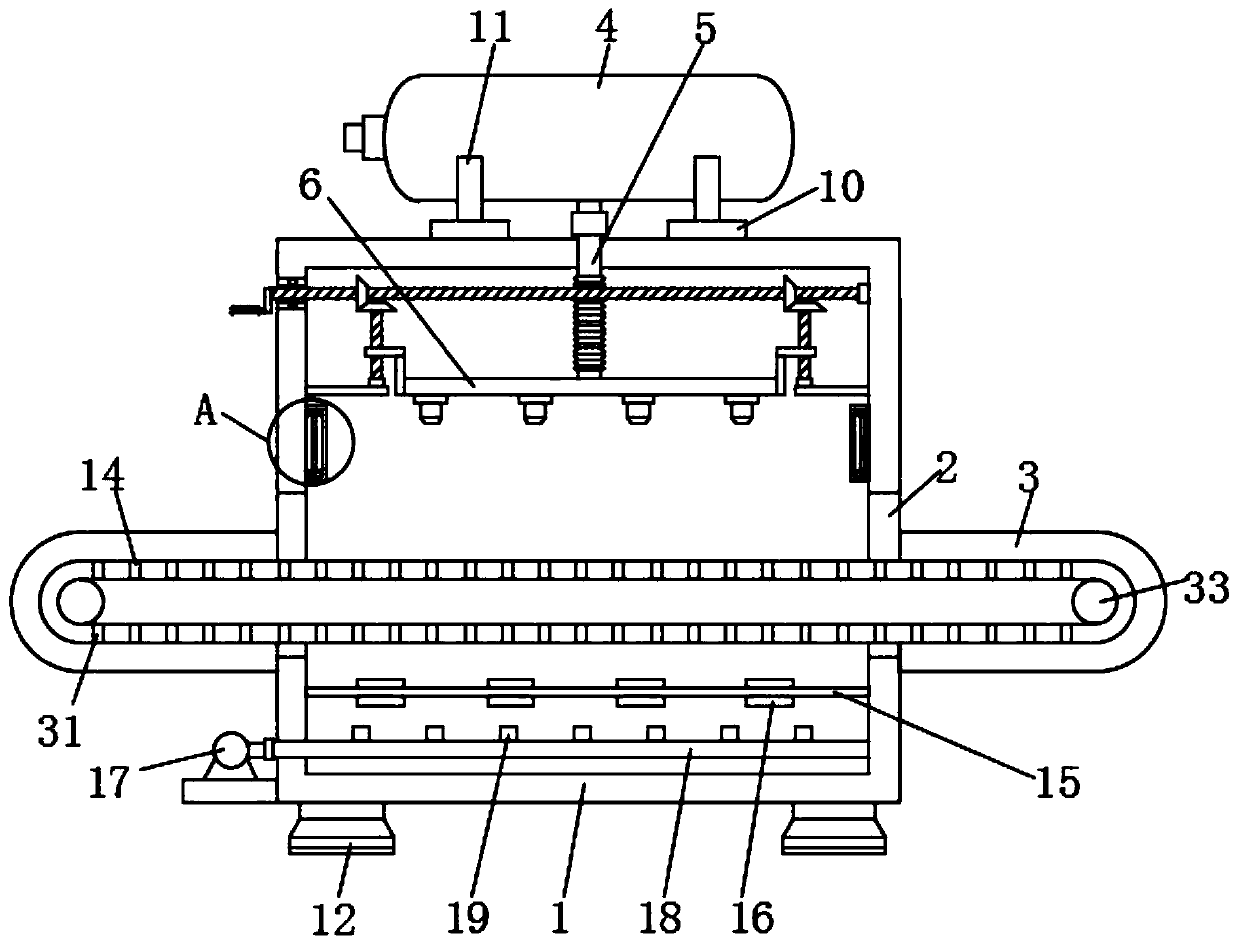

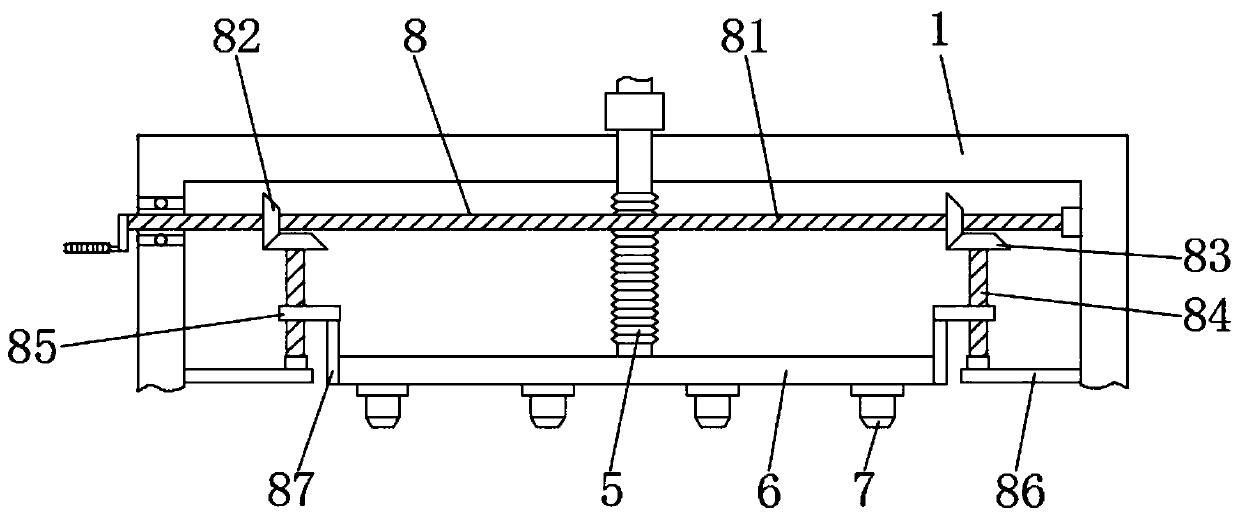

[0042] see Figure 1-6 , a disinfection device for sanitary napkin production, comprising a disinfection box 1, the left and right sides of the disinfection box 1 are provided with through openings 2, the left side of the disinfection box 1 is provided with a transmission device 3, and the left side of the transmission device 3 is from left to The right side runs through two through openings 2 in turn and extends to the right side of the disinfection box 1, the top of the disinfection box 1 is provided with an ethylene oxide gas tank 4, and the bottom of the ethylene oxide gas tank 4 is connected with a gas delivery pipe 5, and the gas delivery pipe 5 The bottom end of the sterilizing box runs through and extends to the interior of the disinfection box 1. A solenoid valve is arranged on the gas delivery pipe 5 and above the disinfection box 1. The model of the solenoid valve is ND15. Air jet pipe 6, the top of air jet pipe 6 communicates with the bottom end of air delivery pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com