Spraying device for green concrete sintered brick production and pouring and using method thereof

A technology of spraying device and concrete, which is applied to clay preparation device, cement mixing device, chemical instrument and method, etc., can solve the problems such as inability to guarantee the smoothness of working surface materials, easy blockage of liquid outlet pipes, and influence on pouring and spraying, etc. To achieve the effect of convenient disassembly, avoiding material adhesion and high crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

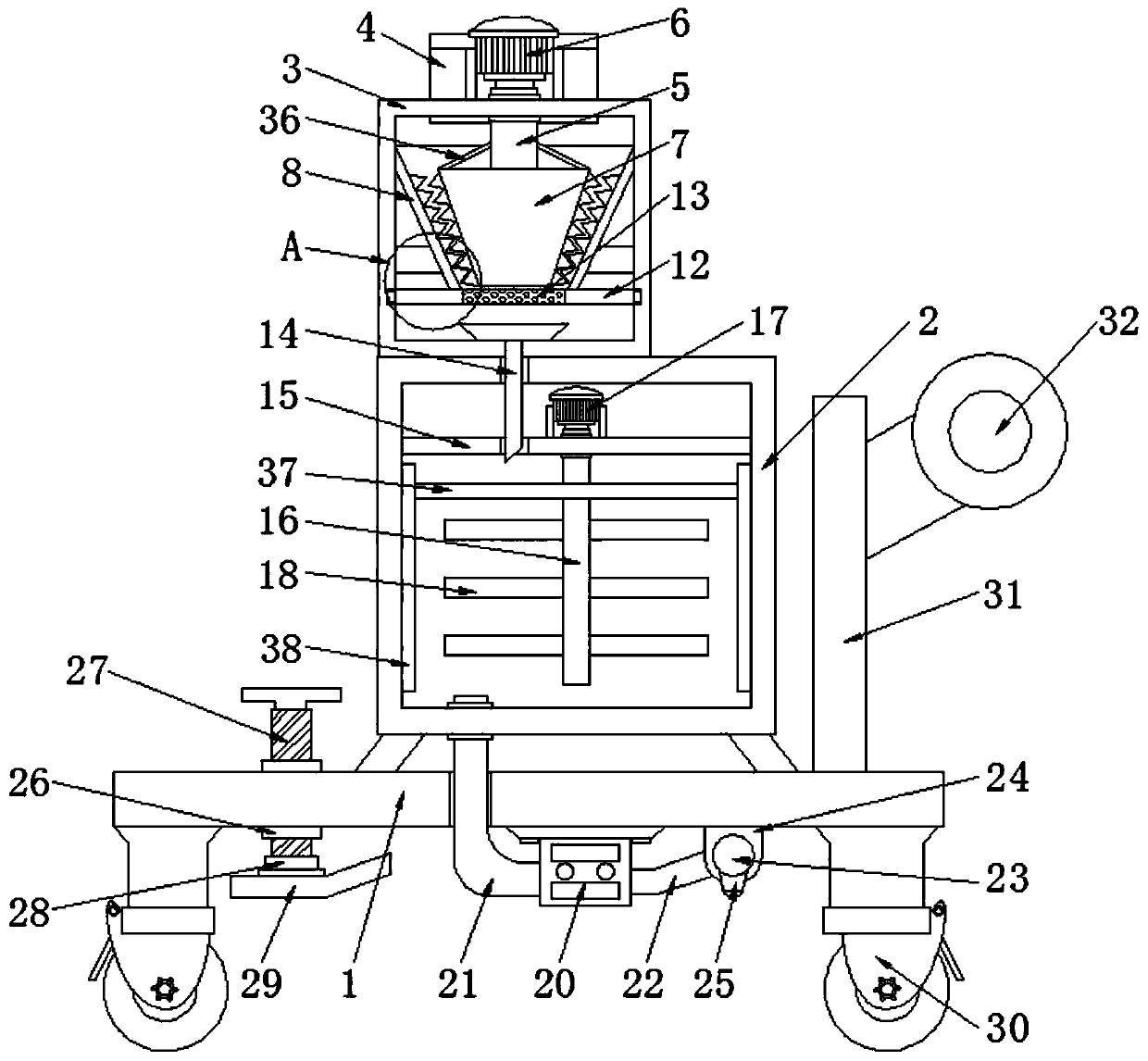

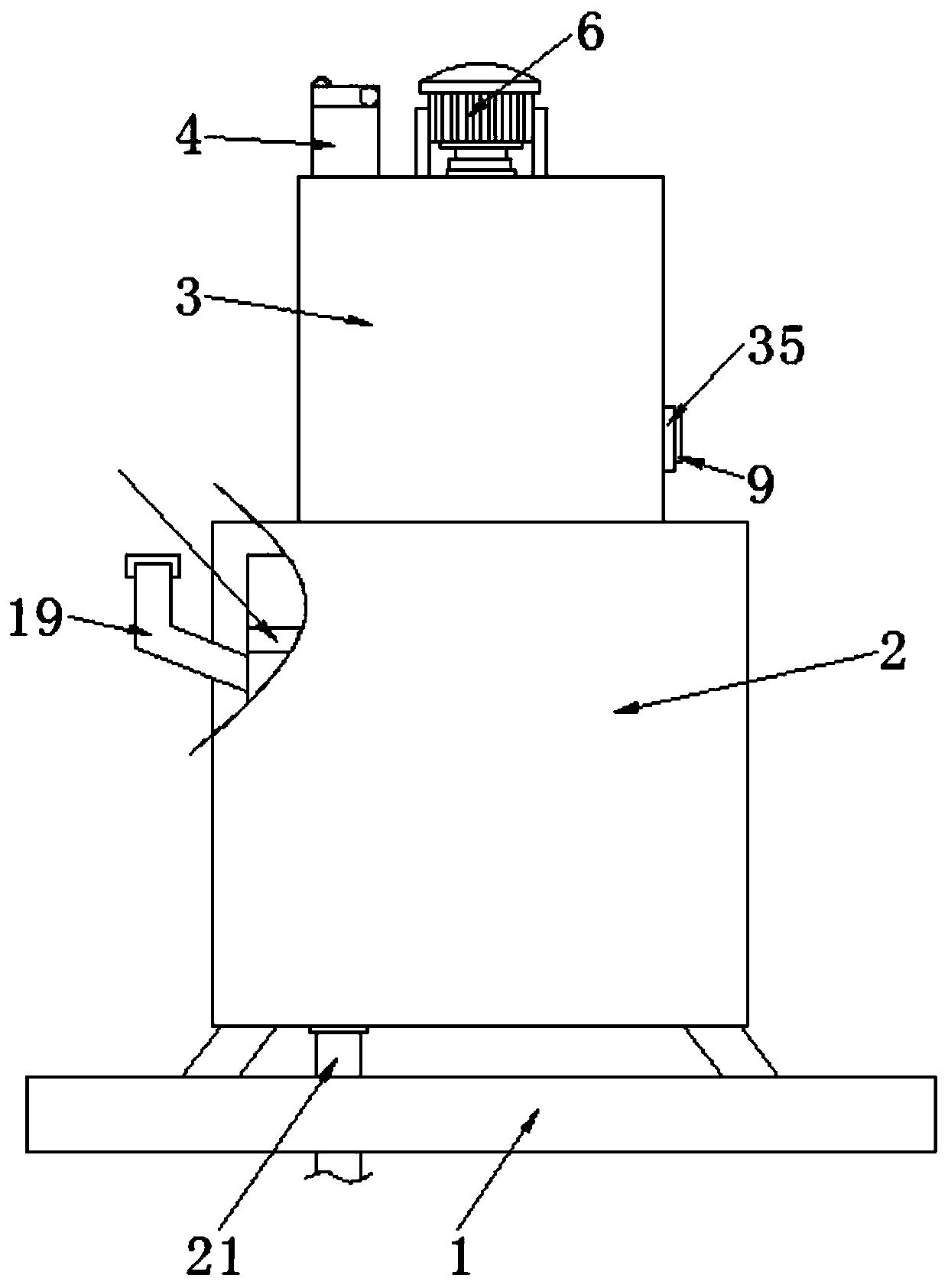

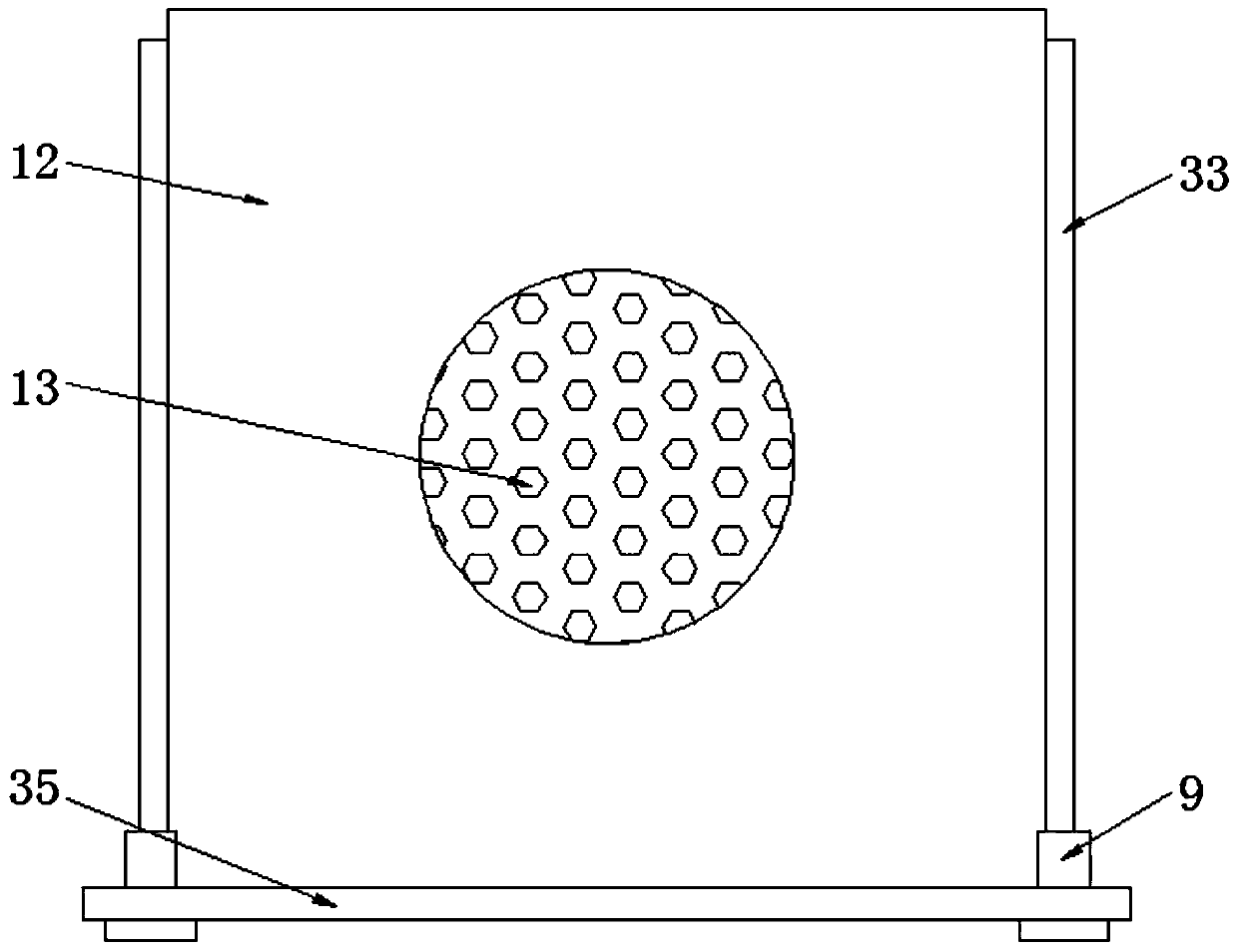

[0035] see Figure 1-6 , the present invention provides a technical solution: a green concrete sintered brick production pouring device, including a bottom plate 1, above the bottom plate 1 is provided with a mixing box 2 and a crushing box 3, the mixing box 2 is fixed by a fixed column a Installed on the upper surface of the bottom plate 1, the crushing box 3 is fixedly installed on the upper surface of the mixing box 2, the upper surface of the crushing box 3 is provided with a feeding hopper 4, and the upper surface of the crushing box 3 is also clamped with a bearing a, and the bearing a The inner wall of the rotating shaft a5 is sleeved with a rotating shaft a5, the top of the rotating shaft a5 is fixedly connected with the output shaft of the driving motor a6, the driving motor a6 is fixedly installed on the upper surface of the crushing box 3, and the bottom end of the rotating shaft a5 is fixedly equipped with a rotating roller 7, and the crushing box The inner wall of 3...

Embodiment 2

[0053] see Figure 1-7 , on the basis of Embodiment 1, the present invention provides another technical solution: the number of connecting plates 37 in the mixing box 2 is two, and the two connecting plates 37 are fixedly connected to the outer surface of the rotating shaft b16, and the two connecting plates The plates 37 are respectively connected to two scrapers 38, and the two connecting plates 37 are used to simultaneously install and support the scrapers 38, so that the connection between the scrapers 38 and the connecting plates 37 is more stable, and then the scraper 38 can be more stable when it rotates with the rotating shaft b16 .

[0054]The working principle and application process of the present invention: people open the cover plate and put the material into the hopper 4, then close the cover plate, the material enters between the fixed roller 8 and the rotating roller 7 under the action of the annular guide plate 36, and starts the drive motor a6 drives the rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com