Electric vehicle attachment stability and quasi-optimal slip rate detection method

A technology of attachment stability and electric vehicles, applied in the direction of brakes, etc., can solve the problems of high cost, high reliability, poor real-time performance and reliability, etc., and achieve the effect of increasing effect, strong reliability and high observation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

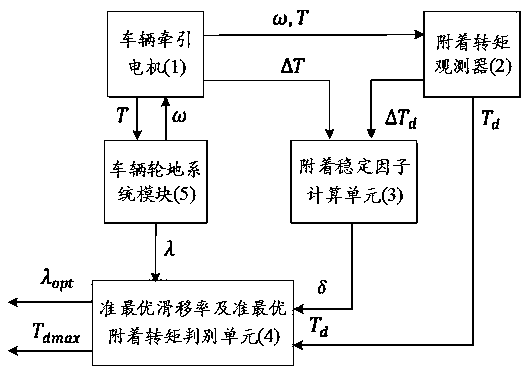

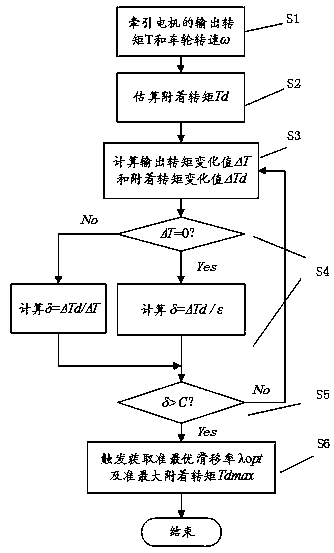

[0052] see figure 1 and figure 2 , the electric vehicle adhesion stability and quasi-optimal slip rate detection method is characterized in that the operation steps are as follows:

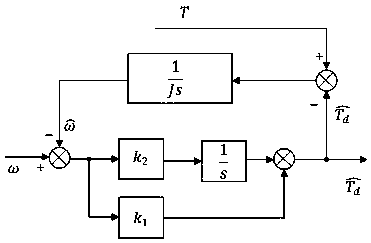

[0053] (1) Establish a closed-loop disturbance observer DOB to observe the tire-ground adhesion torque T d;

[0054] (2) Using the observed tire ground adhesion torque T d Calculate its change ΔT d =T d (t 2 )-T d (t 1 ), use the electric vehicle traction motor torque T to calculate its change value ΔT=T(t 2 )-T(t 1 ); t 1 is the first detection time, t 2 is the second detection moment, where the traction torque T is the given torque, or the torque value actually output by the traction motor;

[0055] (3) Using ΔT d The ratio of ΔT and ΔT to calculate the adhesion stability factor δ, when ΔT is 0, the denominator is set to a constant;

[0056] (4) Analyze the variation law of the attachment stability factor. When the attachment stability factor δ changes sharply from positive to neg...

Embodiment 2

[0058] like figure 1 As shown, a method for detecting adhesion stability and quasi-optimal slip rate of an electric vehicle is characterized in that it includes an interrelated vehicle traction motor module, an adhesion torque observation module, an adhesion stability factor calculation unit, and a quasi-optimal slip. rate and quasi-adhesion torque judgment unit and vehicle wheel-ground system module, etc.

[0059] The vehicle traction motor module is used to obtain the output torque T of the traction motor and the wheel speed ω of the vehicle, and calculate the variation ΔT of the traction torque in real time. The traction torque T can be estimated by measuring the armature current parameters of the driving motor, etc., or the traction torque can be obtained by the given command input by the driver to the pedal; and the motor torque change value ΔT=T(t(t) is calculated in real time. 2 )-T(t 1 ); t 1 is the first detection time, t 2 is the second detection time.

[0060] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com