Double-screw conveying tank

A twin-screw and conveying tank technology, applied in the field of material transportation, can solve problems such as idling of the screw machine, easy blockage of the screw machine, poor sealing of the system, etc., and achieve the effect of increasing the contact area, improving the transportation efficiency, and facilitating operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The invention provides a twin-screw conveying tank material with strong adaptability, stable and continuous operation, high transportation efficiency, and avoids material loss during transportation by avoiding dead ends.

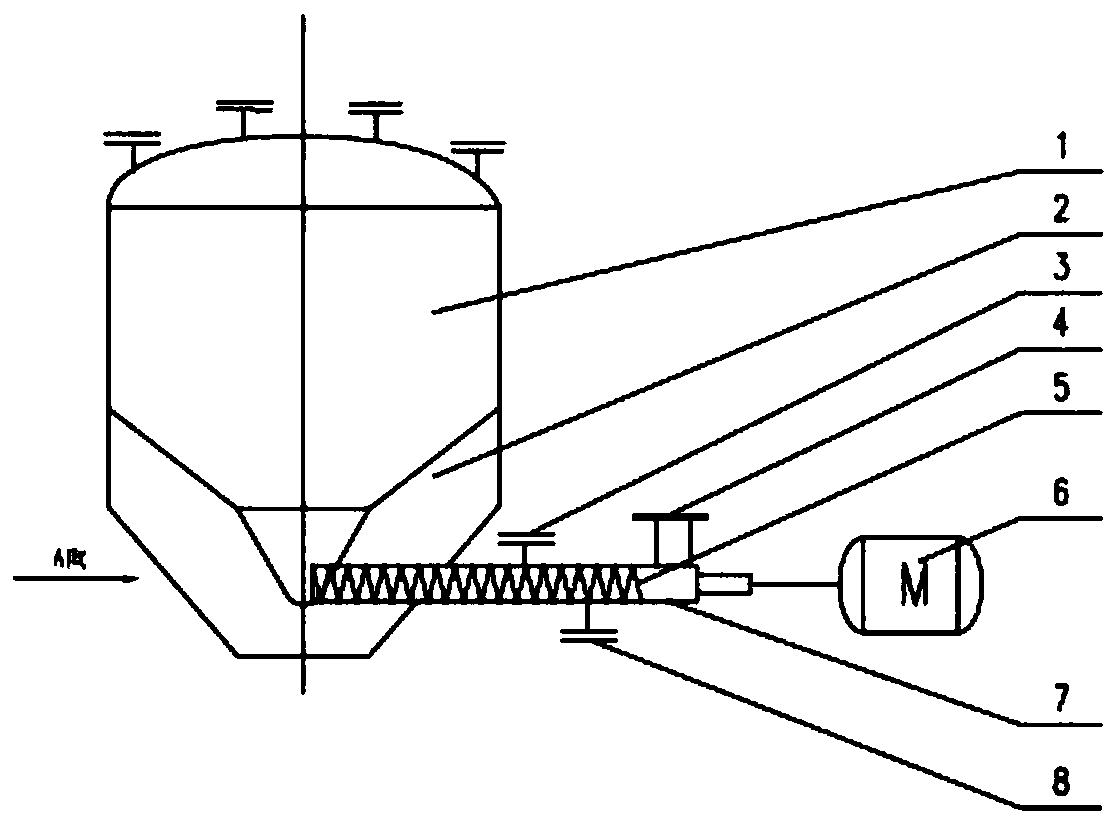

[0022] like figure 1 A kind of twin-screw conveying tank shown, comprises tank body 1, twin-screw 5 and motor 6, and described tank body 1 is provided with feed inlet, tank body shell and packing layer 2, and described tank body shell and packing layer 2 A conical space is formed, and the twin-screw 5 is inserted horizontally from the outside of the tank so that one end of the twin-screw 5 is located in the conical space, and the other end of the twin-screw 5 is connected to a motor 6 .

[0023] The tank body is provided with 2 feeding ports and 2 connecting ports. Filler layer 2 is filled with smooth ceramics.

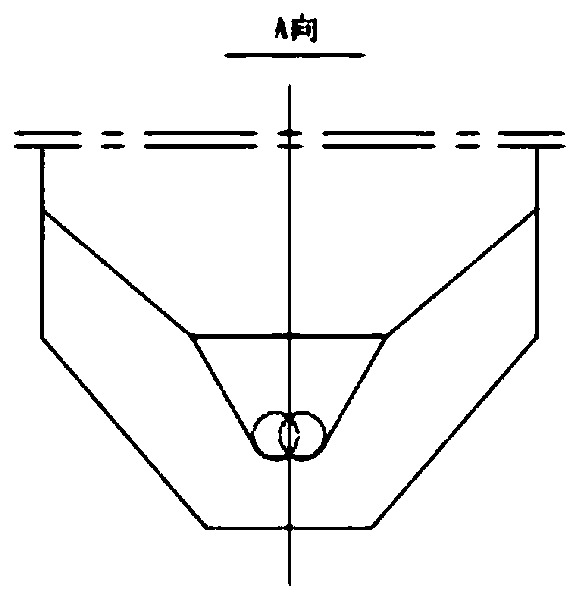

[0024] like figure 2 The left view of the twin-screw conveying tank, the size of the screw matches the conical space.

[0025] The twin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com