Cable winding device used for electric power engineering

A winding device and power engineering technology, applied in hoisting devices, cable laying equipment, transportation and packaging, etc., can solve the problems of heavy drum weight and inconvenient unloading, and achieve the effect of convenient disassembly and installation, labor saving and stability assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

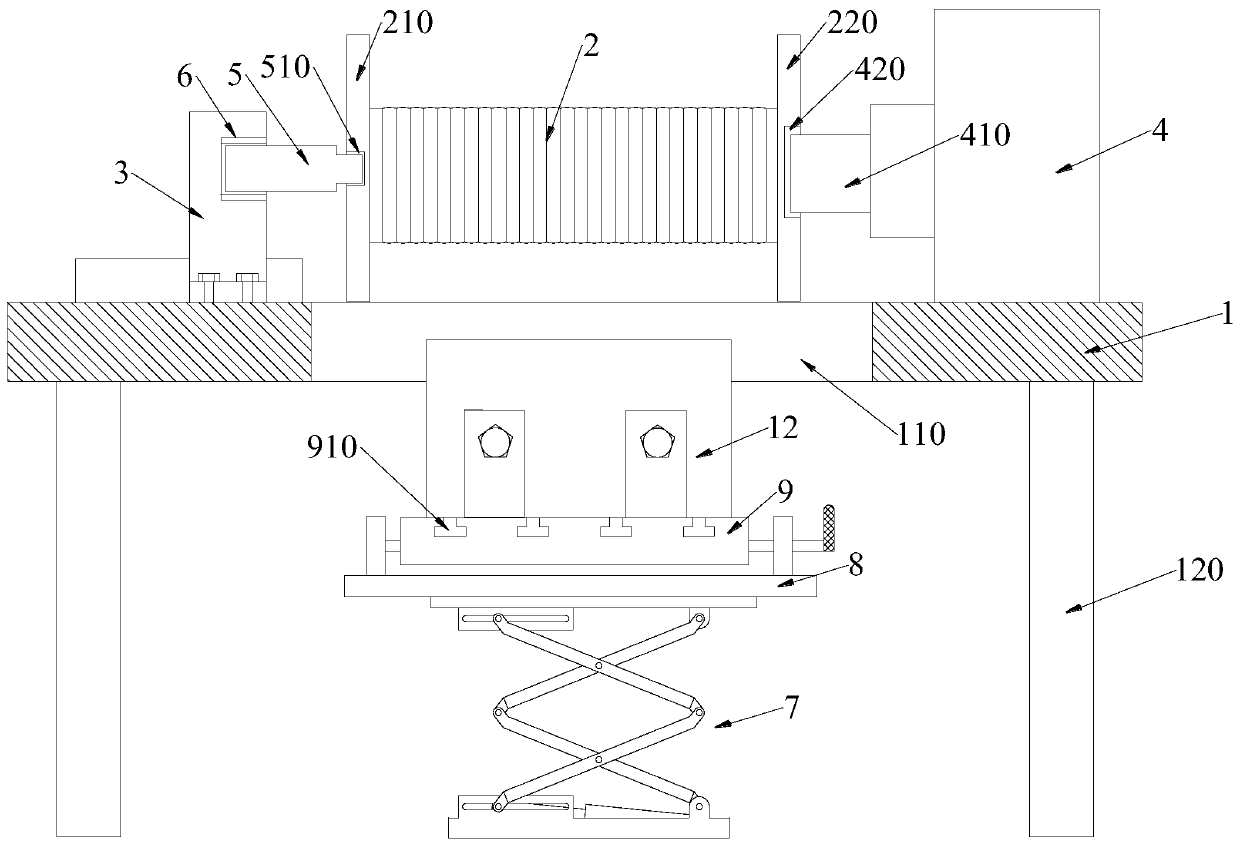

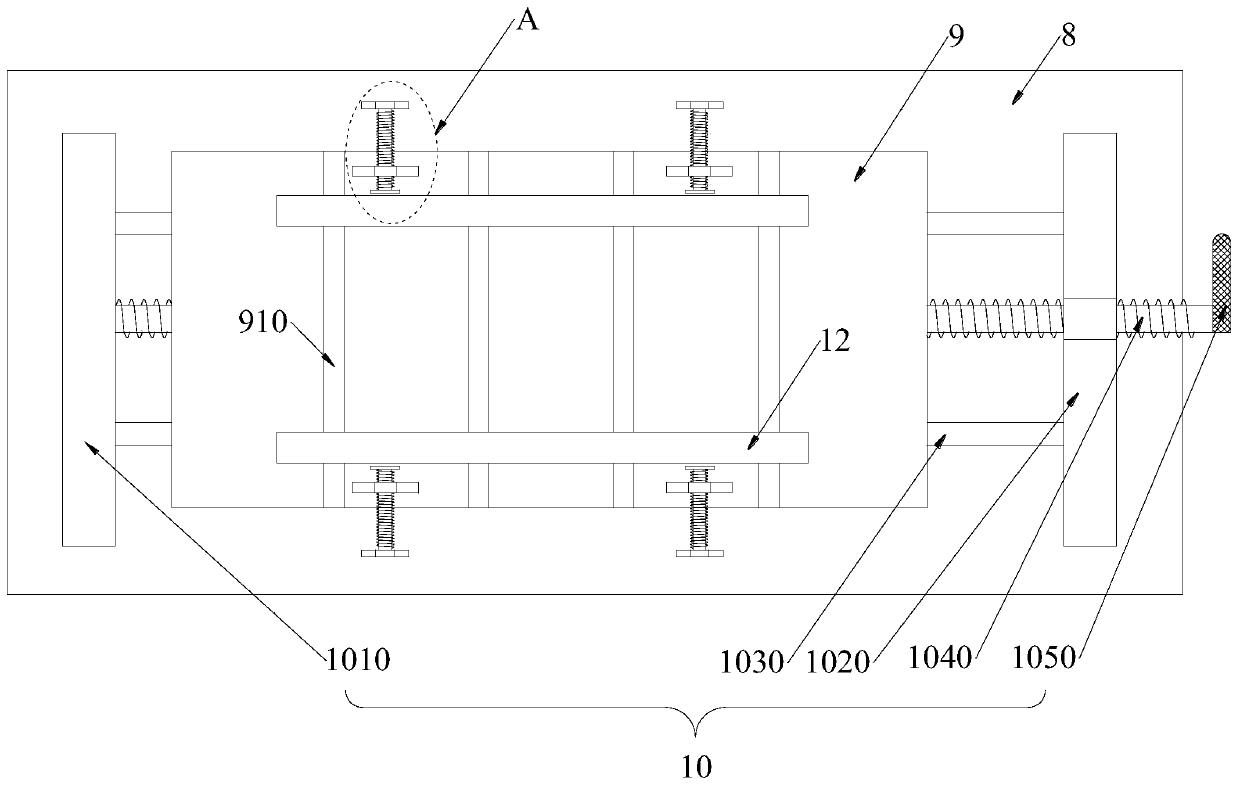

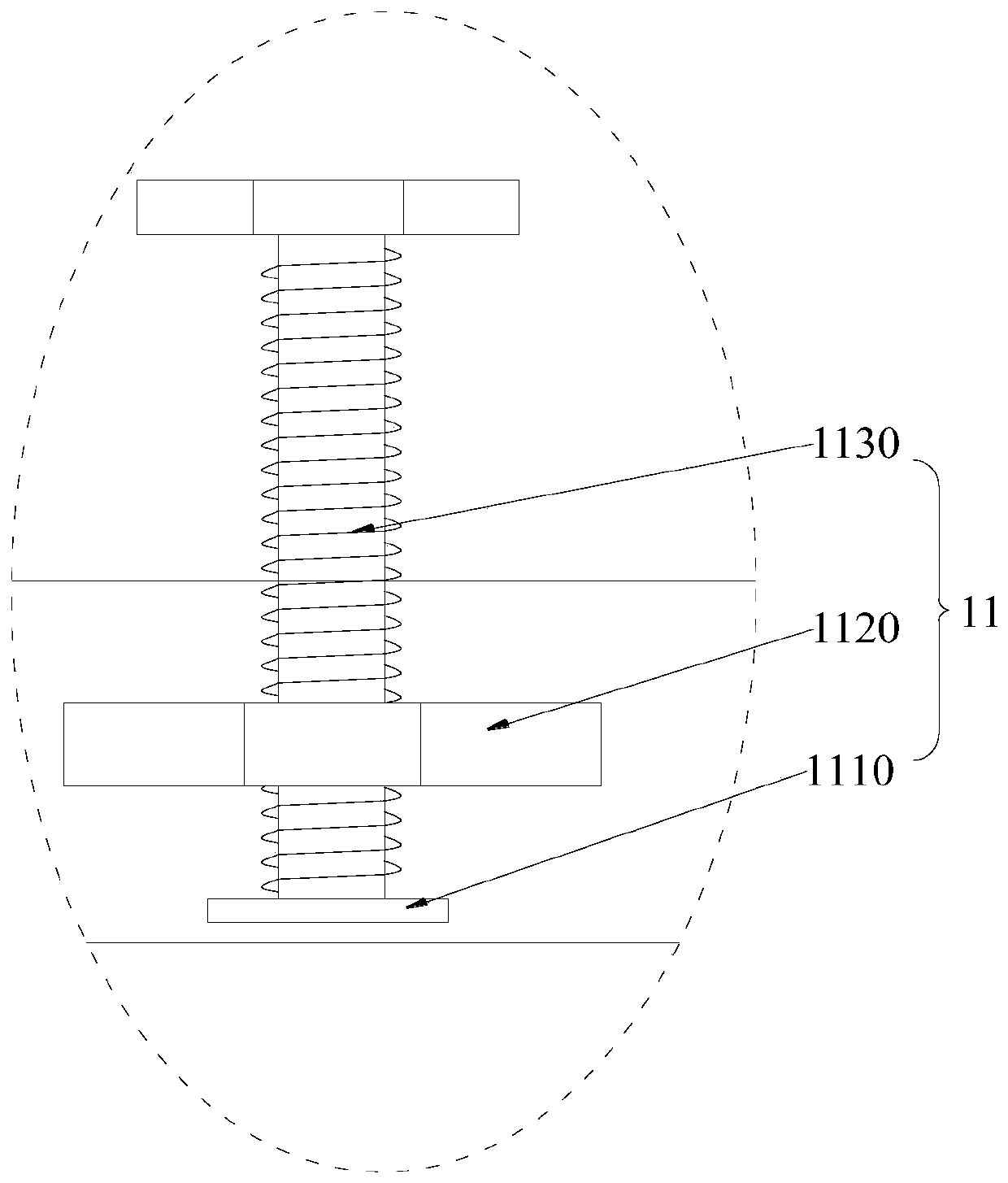

[0028] The cable winding device for electric power engineering of the present invention comprises a placing table 1, a plurality of legs 120 are arranged at the lower end of the placing table 1, a through groove 110 is opened in the middle of the placing table 1, and a roller 2 is arranged above the through groove 110, The left and right sides of the drum 2 are respectively connected with a first turntable 210 and a second turntable 220, and the left and right sides of the through groove 110 are respectively provided with a slide seat 3 and a drive motor 4, the slide seat 3 can move left and right, and the slide seat 3 and the first turntable The driven shaft 5 is connected between the turntables 210, and the drive shaft 410 of the drive motor 4 is connected to the second turntable 220. A lifting plate 8 is provided below the through groove 110, and a lifting drive device 7 is provided at the lower end of the lifting plate 8. The upper end of the plate 8 is provided with an adj...

Embodiment 2

[0031] This embodiment is further optimized on the basis of Embodiment 1 as follows: the middle part of the first turntable 210 is provided with a first positioning groove 510, the middle part of the second turntable 220 is provided with a second positioning groove 420, and the upper end of the slide seat 3 A bearing 6 is provided, one end of the driven shaft 5 is rotationally connected with the bearing 6 , and the other end of the driven shaft 5 is interference fit with the first positioning groove 510 ; the driving shaft 410 is interference fit with the second positioning groove 420 .

[0032] After adopting the above technical solution, the first turntable 210 is provided with a first positioning groove 510, the second turntable 220 is provided with a second positioning groove 420, the driven shaft 5 and the first positioning groove 510 and the driving shaft 410 and the second positioning groove 420 Both are interference fits. When installing the drum 2, the installation is ...

Embodiment 3

[0034]This embodiment is further optimized on the basis of Embodiment 1 as follows: the upper end of the placing table 1 is provided with a slide block 310, the lower end of the slide seat 3 is provided with a chute matching with the slide block 310, the two sides of the slide block 310 There are a plurality of positioning holes 320 on the side, and a plurality of bolt assemblies 330 matching with the positioning holes 320 are arranged on both sides of the sliding seat 3 . The slide block 310 is a dovetail block, and the chute is a dovetail groove adapted to the dovetail block.

[0035] After adopting the above technical solution, the sliding seat 3 can move left and right through the slider 310, and then realize the left and right movement of the driven shaft 5, so that the driven shaft 5 can enter the first positioning groove 510 in the process of moving to the right, and When dismounting, the sliding seat 3 first moves away from the roller 2, and the sliding seat 3 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com