High-strength nanometer reinforced steel capable of inhibiting marine organism fouling and preparation method thereof

A marine biofouling and high-strength technology, applied in the field of high-strength steel materials, can solve problems such as restricting marine fouling resistance, achieve the effects of inhibiting marine biofouling performance, excellent structural mechanical properties, and reducing the risk of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

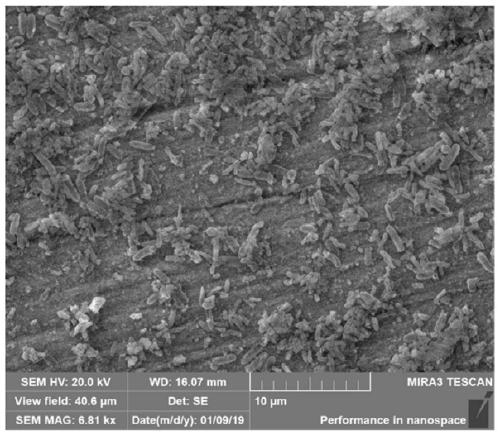

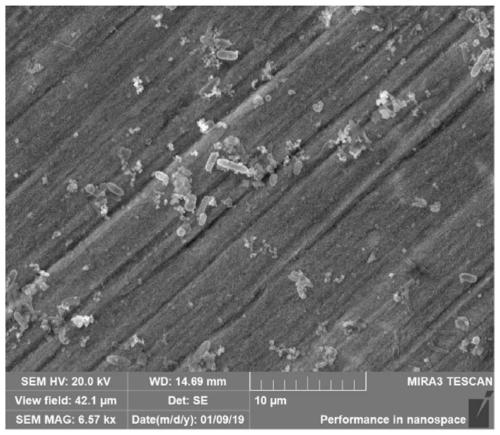

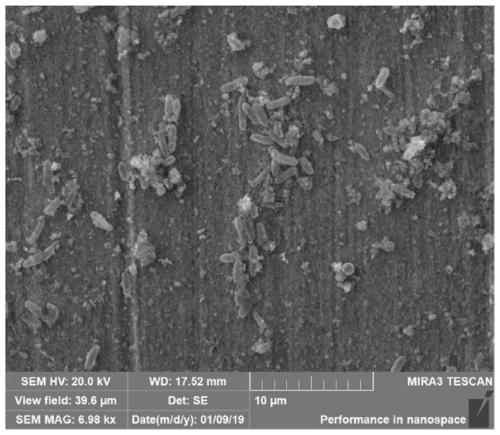

Image

Examples

Embodiment Construction

[0036] In the following, the present invention will be described by comparing different examples, which are for illustrative purposes only, and the present invention is not limited to these examples.

[0037] In the specific implementation process, the preparation method of the high-strength nano-reinforced steel with marine biofouling resistance performance of the present invention is as follows:

[0038] (1) The raw materials were mixed according to the chemical composition of the present invention, and high-strength steel ingots were obtained through vacuum induction smelting and pouring. Table 1 shows the chemical composition of the steels of the examples and comparative examples.

[0039] (2) Forging the steel ingot in the austenite single-phase region: the initial forging temperature is 1080-1150°C, the final forging temperature is 950-1000°C, the forging ratio is 6-8, and air-cooled to room temperature after forging.

[0040] (3) The mechanical performance samples were ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com