Composite fiber film for filtering air

A technology of composite fiber membrane and air filtration, which is applied in the direction of fiber type, fiber treatment, membrane technology, etc. It can solve the problems of poor adsorption capacity, poor filter material strength, and increased manufacturing material costs, and achieve good structural mechanical properties and scrub resistance General impact, ensure the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

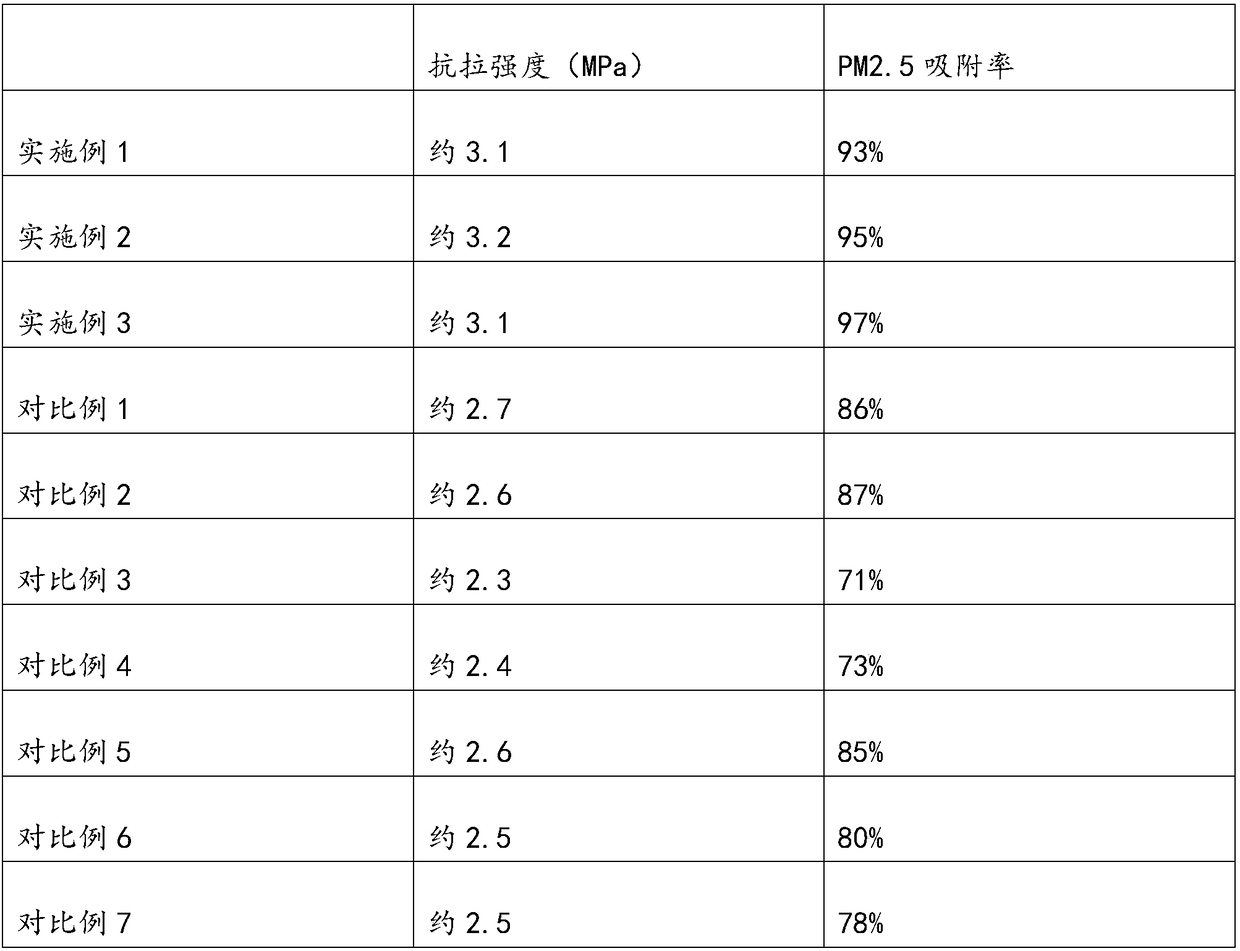

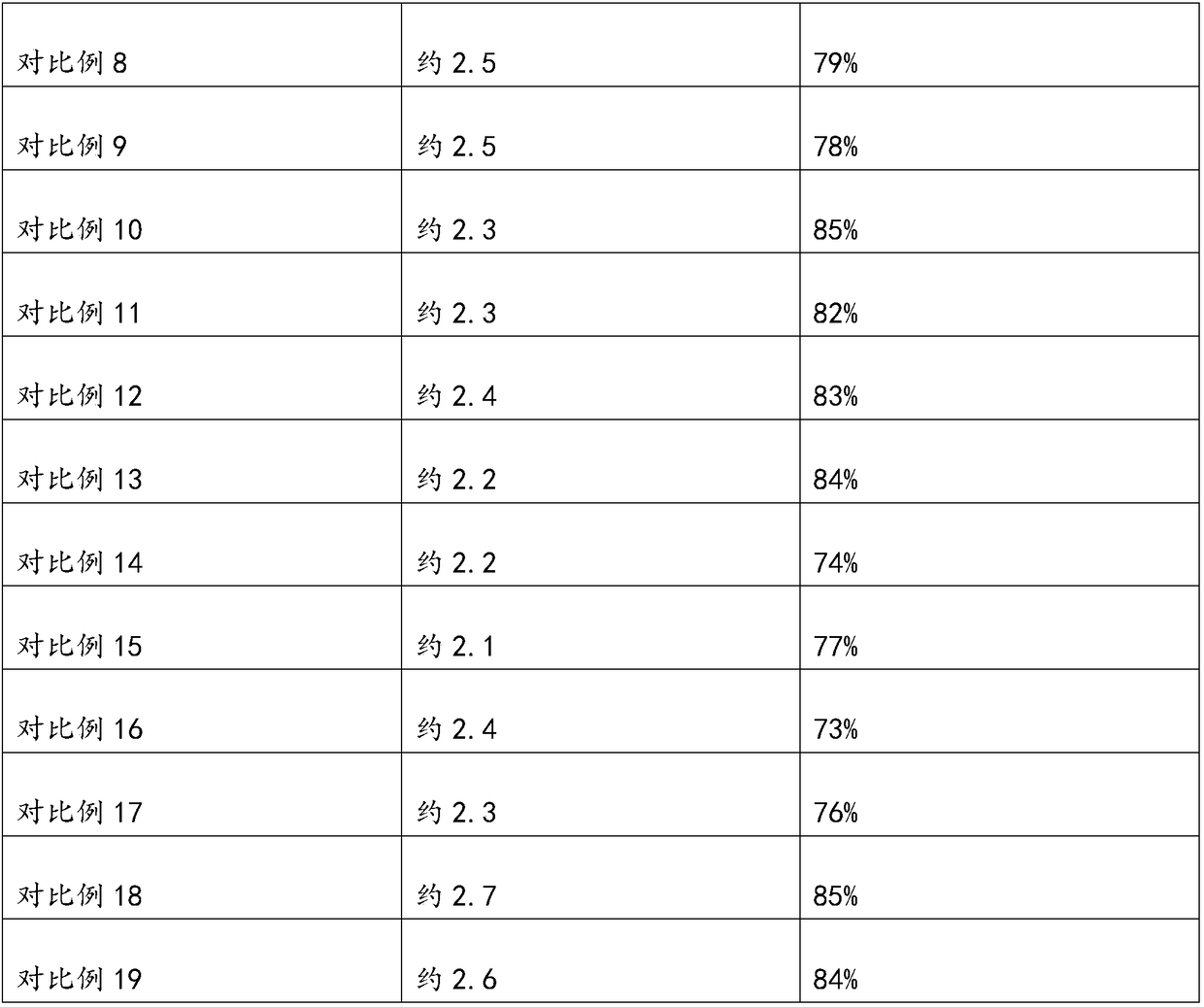

Examples

Embodiment 1

[0017] The composite fiber membrane is prepared by the following method: EVA hot-melt adhesive membrane is provided; the EVA hot-melt adhesive membrane is surface activated; the first electrospinning method is used to form the first EVA hot-melt adhesive membrane surface after activation. PET fiber layer; Utilize the second electrospinning method to form the first PA6 fiber layer on the surface of the first PET fiber layer; Utilize the third electrospinning method to form a PVA / PA6 composite fiber layer on the first PA6 fiber layer surface; Utilize the fourth The first PVA fiber layer is formed on the surface of the PVA / PA6 composite fiber layer by the electrospinning method; the second PET fiber layer is formed on the surface of the first PVA fiber layer by the fifth electrospinning method. The surface activation of the EVA hot-melt adhesive film is specifically: configuring a dilute solution of the silane coupling agent; coating the dilute solution of the silane coupling agen...

Embodiment 2

[0019]The composite fiber membrane is prepared by the following method: EVA hot-melt adhesive membrane is provided; the EVA hot-melt adhesive membrane is surface activated; the first electrospinning method is used to form the first EVA hot-melt adhesive membrane surface after activation. PET fiber layer; Utilize the second electrospinning method to form the first PA6 fiber layer on the surface of the first PET fiber layer; Utilize the third electrospinning method to form a PVA / PA6 composite fiber layer on the first PA6 fiber layer surface; Utilize the fourth The first PVA fiber layer is formed on the surface of the PVA / PA6 composite fiber layer by the electrospinning method; the second PET fiber layer is formed on the surface of the first PVA fiber layer by the fifth electrospinning method. The surface activation of the EVA hot-melt adhesive film is specifically: configuring a dilute solution of the silane coupling agent; coating the dilute solution of the silane coupling agent...

Embodiment 3

[0021] The composite fiber membrane is prepared by the following method: EVA hot-melt adhesive membrane is provided; the EVA hot-melt adhesive membrane is surface activated; the first electrospinning method is used to form the first EVA hot-melt adhesive membrane surface after activation. PET fiber layer; Utilize the second electrospinning method to form the first PA6 fiber layer on the surface of the first PET fiber layer; Utilize the third electrospinning method to form a PVA / PA6 composite fiber layer on the first PA6 fiber layer surface; Utilize the fourth The first PVA fiber layer is formed on the surface of the PVA / PA6 composite fiber layer by the electrospinning method; the second PET fiber layer is formed on the surface of the first PVA fiber layer by the fifth electrospinning method. The surface activation of the EVA hot-melt adhesive film is specifically: configuring a dilute solution of the silane coupling agent; coating the dilute solution of the silane coupling agen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com