Hip prosthesis

A hip joint prosthesis and volume technology, applied in the field of hip joint prosthesis, can solve problems such as uneven distribution of elastic modulus, insufficient uniformity, self-weight, etc., achieve good structural mechanical properties, ensure uniformity, and prevent down The effect of sinking and spinning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

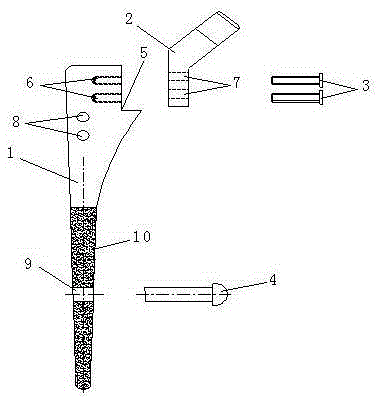

[0025] As attached to the manual figure 1 As shown, a hip joint prosthesis includes a femoral stem 1, a femoral neck 2, a connecting screw 3 and a fastening rod 4; the head of the femoral stem 1 is provided with an L-shaped section 5, and the L-shaped section 5 Two threaded holes 6 are provided on the longitudinal surface of the femoral neck 2; the lower part of the femoral neck 2 is set as a positive column, and the upper part is set as an offset inclined column; the lower part of the femoral neck 2 is provided with two through holes 7; two connecting The screws 3 respectively pass through the through holes 7 and are correspondingly connected with the threaded holes 6; the middle part of the femoral stem 1 is provided with two positioning holes 8; Fitted with a fastening rod 4, both ends of the fastening rod 4 protrude from the two ends of the hole 9; the lower part 10 of the femoral stem 1 is made of multi-level hole material, and is welded by conventional laser or bonding ...

Embodiment 2

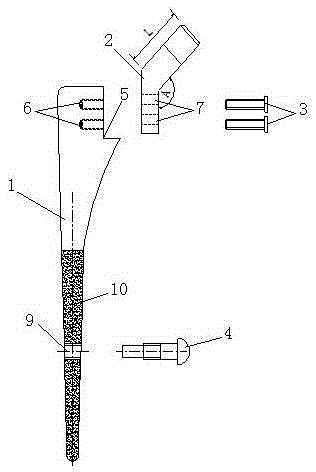

[0037] As attached to the manual figure 2 As shown, a hip joint prosthesis includes a femoral stem 1, a femoral neck 2, a connecting screw 3 and a fastening rod 4; the head of the femoral stem 1 is provided with an L-shaped section 5, and the L-shaped section 5 Two threaded holes 6 are provided on the longitudinal surface of the femoral neck 2; the lower part of the femoral neck 2 is set as a positive column, and the upper part is set as an offset inclined column; the lower part of the femoral neck 2 is provided with two through holes 7; two connecting The screws 3 pass through the through holes 7 and are correspondingly connected with the threaded holes 6; the lower part 10 of the handle body of the femoral stem 1 is provided with a hole 9, and the hole 9 is a threaded hole; In the hole 9, and both ends of the fastening rod 4 protrude from the two ends of the hole 9; the lower part 10 of the handle body of the femoral stem 1 is made of multi-level hole material, and is welde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com