Structural water manufacturing equipment based on absorption spectral line frequency

A technology for manufacturing equipment and absorption lines, which is applied in the field of structural water manufacturing equipment, can solve the problems of changing the basic structure of water clusters and single means, and achieve the effects of wide application, high dissolved gas content and obvious effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

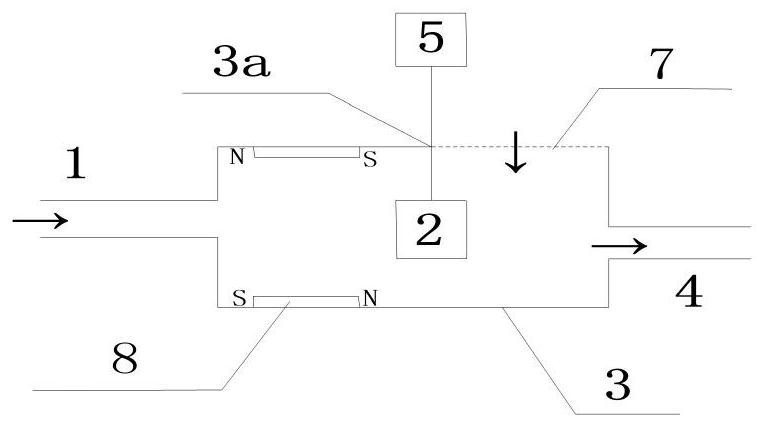

[0048] Design a structured water manufacturing equipment according to the present invention, including a water inlet pipe 1, an oscillator 2, a gas combination device 3, a water outlet pipe 4 and a control circuit 5; the water inlet pipe 1 and the water outlet pipe 4 are made of plastic steel with a diameter of 50mm to make.

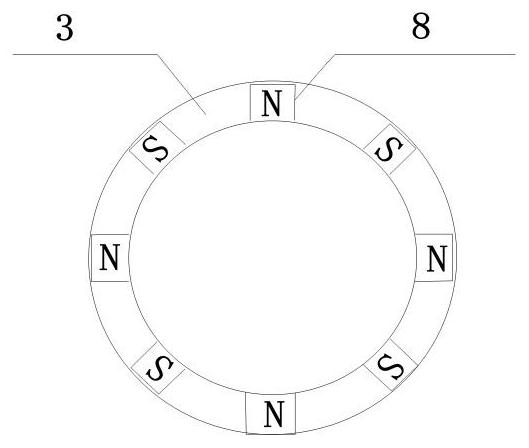

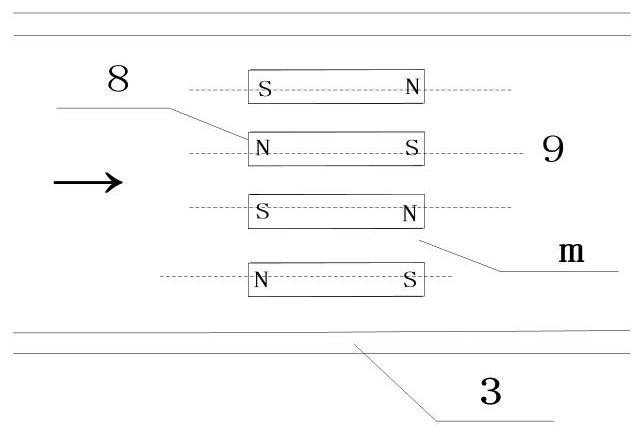

[0049] The water pump of the gas combination device 3 is external, and the mixing chamber is designed as a barrel with a diameter of 280mm and a length of 450mm. The inner wall of the barrel is evenly arranged with 8 permanent magnets with alternating N / S poles 8. The magnetic flux of the permanent magnets The density is at least 10000 Gauss, the arrangement feature is that the N / S magnetic poles are regularly reversed and alternated along the liquid channel, and the magnetic pole line 9 is set along the direction of the water flow, such as Figure 2a with Figure 2b Shown; a barrel-shaped gas-synthesis device 3 is provided with two round holes, respectively...

Embodiment 2

[0054] Technical improvements are made on the basic scheme of Example 1.

[0055] 1) The oscillation frequency of oscillator 2 is changed to 1.2×10 10 Frequency band of Hz occurs;

[0056] 2) Cancel the semi-permeable membrane 7 of the gas-sealing device 3 and change it to a sealed mixing chamber with holes;

[0057] 3) An oxygen supply device 10 is added, and the oxygen output end of the oxygen supply device 10 is connected to the hole provided in the mixing chamber.

[0058] The overall installation structure of this embodiment is as Figure 4 Shown.

[0059] The difference between this embodiment and embodiment 1 is that since this embodiment is mixed with water is oxygen, the obtained structured water has a higher oxygen content, and the oxygen content in the saturated concentration state can be as high as 10-30mg / L Compared with ordinary water, the oxygen content is one order of magnitude higher; the structured water with high oxygen content can be used to treat black and odorous ...

Embodiment 3

[0062] A supercharging device 6 is added to the basic technical solution of embodiment 1.

[0063] The pressurizing device 6 includes a pressure pump and a pressurizing chamber. The pressure pump is used to pump water into the pressurizing chamber so that the structural water can be pressurized. The water inlet end of the pressurizing device 6 is connected to the gas combination device, and the water outlet of the pressurizing device 6 The end is connected to the water outlet pipe 4, and the pressurization process is set to alternate processing between 2 atmospheres and normal pressure at an interval of 5 minutes.

[0064] The overall installation structure of this embodiment is as Figure 5 As shown, the structured water pressurized by the pressurizing device 6 can stably exist for a longer period of time in the amount of dissolved oxygen (air) inside. Generally, the saturated half-life of the dissolved air can be as long as 3-6 months, thus having sufficient technical conditions ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com