A Gravity Vertical Retaining Wall Structure

A kind of retaining wall, gravity type technology, applied in the direction of underwater structure, infrastructure engineering, construction, etc., can solve the problem of unable to reinforce the retaining wall, unable to assist the construction personnel to increase the cross-sectional area of the lower end, gravity type retaining wall construction Cumbersome and other problems, to achieve the effect of increasing the cross-sectional area and increasing the stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

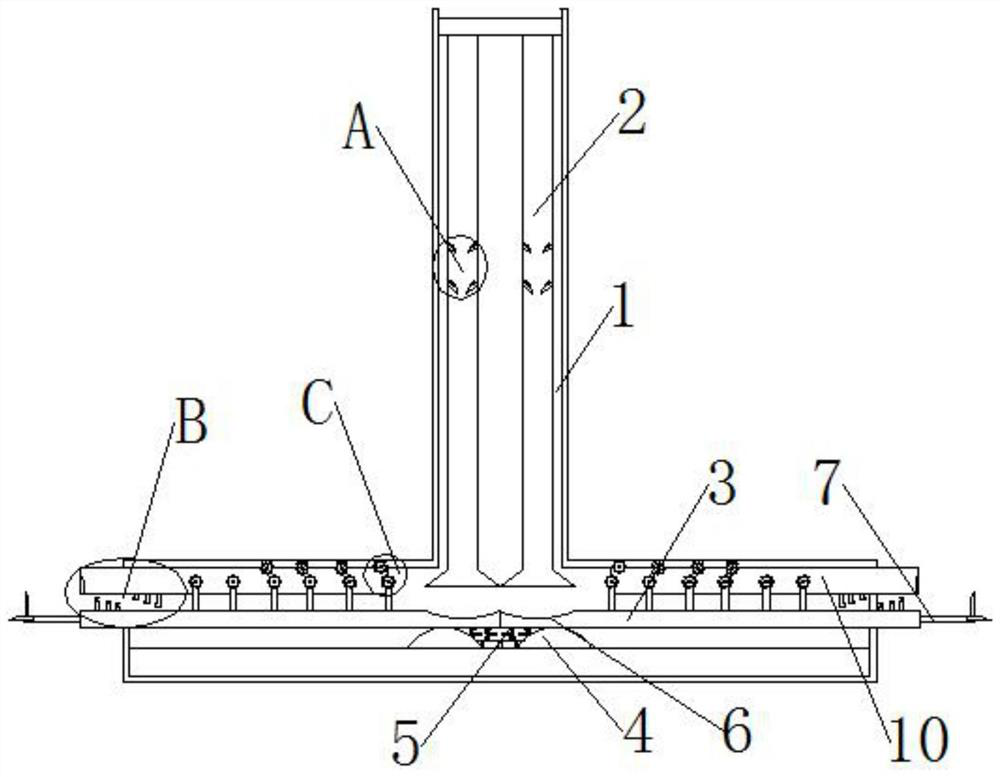

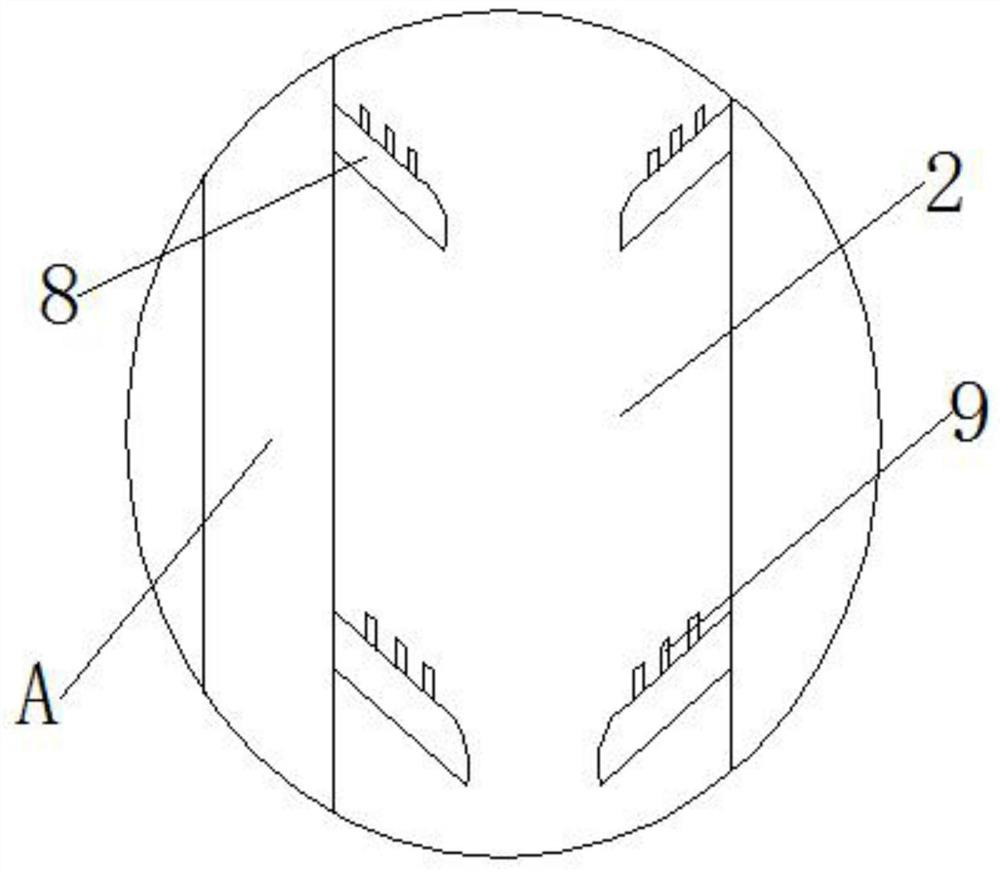

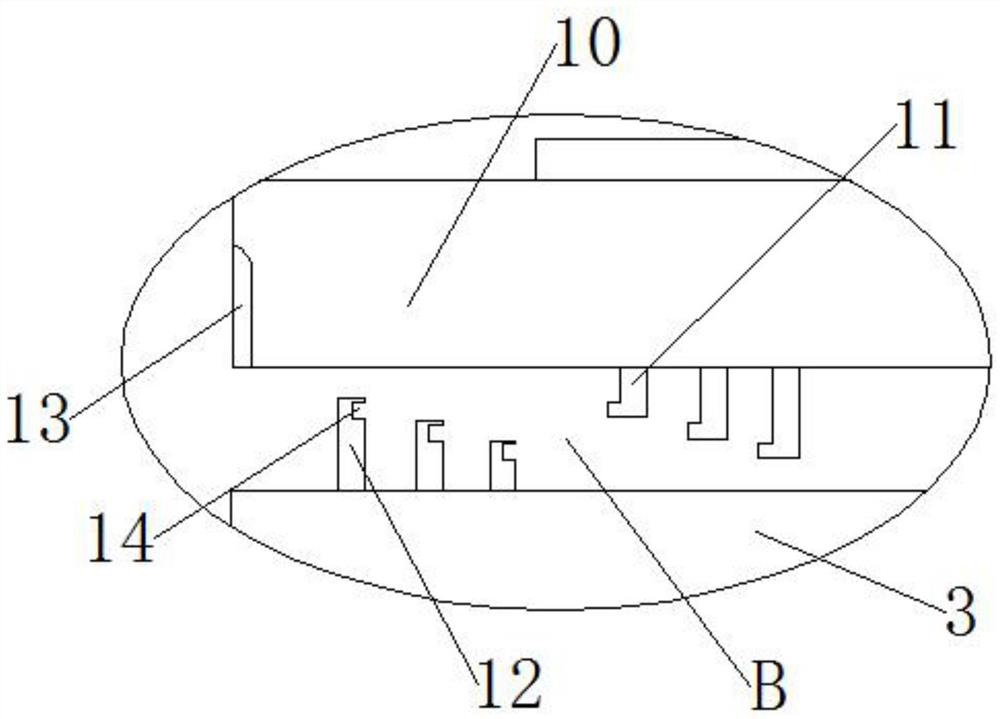

[0029] as attached figure 1 to attach Figure 6 Shown: a gravity-type vertical retaining wall structure, including a wall 1, the interior of the wall 1 is provided with a through pipe 2, the interior of the through pipe 2 is provided with a deceleration plate 8, and one end of the deceleration plate 8 is provided with a deceleration block 9, One end of the body of wall 1 is provided with a rotating plate 3, one end of the rotating plate 3 is provided with a rotating ball 4, one side of the rotating ball 4 is provided with a spring 5, one side of the rotating plate 3 is embedded with a rotating groove 6, and one end of the rotating plate 3 There is a lower docking frame 12, one side of the lower docking frame 12 is provided with a docking groove 14, one end of the rotating plate 3 is provided with a support rod 16, one end of the support rod 16 is provided with a gear 15, and one side of the gear 15 is provided with a pulley 17 The outside of the gear 15 and the pulley 17 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com