Construction method of heat-preservation outer wall

A construction method and technology for thermal insulation exterior walls, applied in thermal insulation, building components, buildings, etc., can solve the problems of easy cracking of thermal insulation layers, poor thermal insulation effect of thermal insulation external walls, etc., and achieve good thermal insulation performance, ensure integrity, and fix firmly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0039] A construction method for thermal insulation exterior walls disclosed by the present invention comprises the following steps:

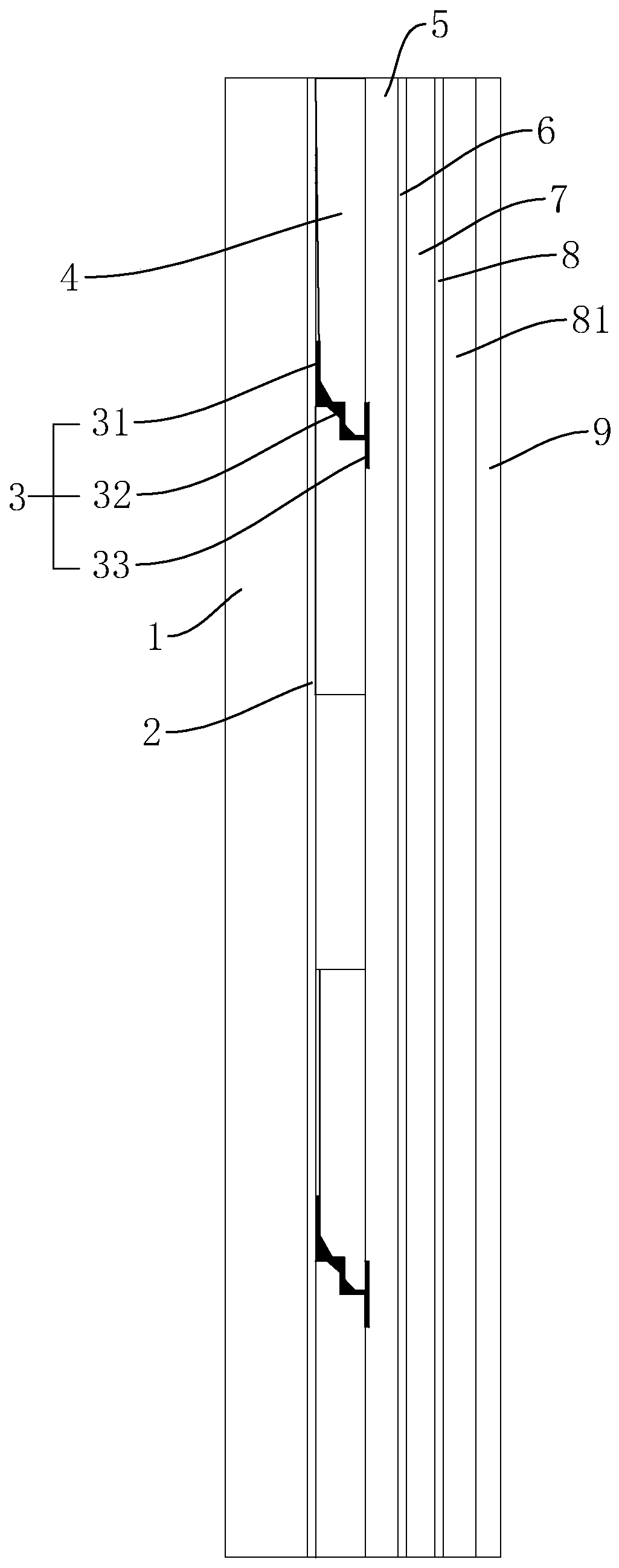

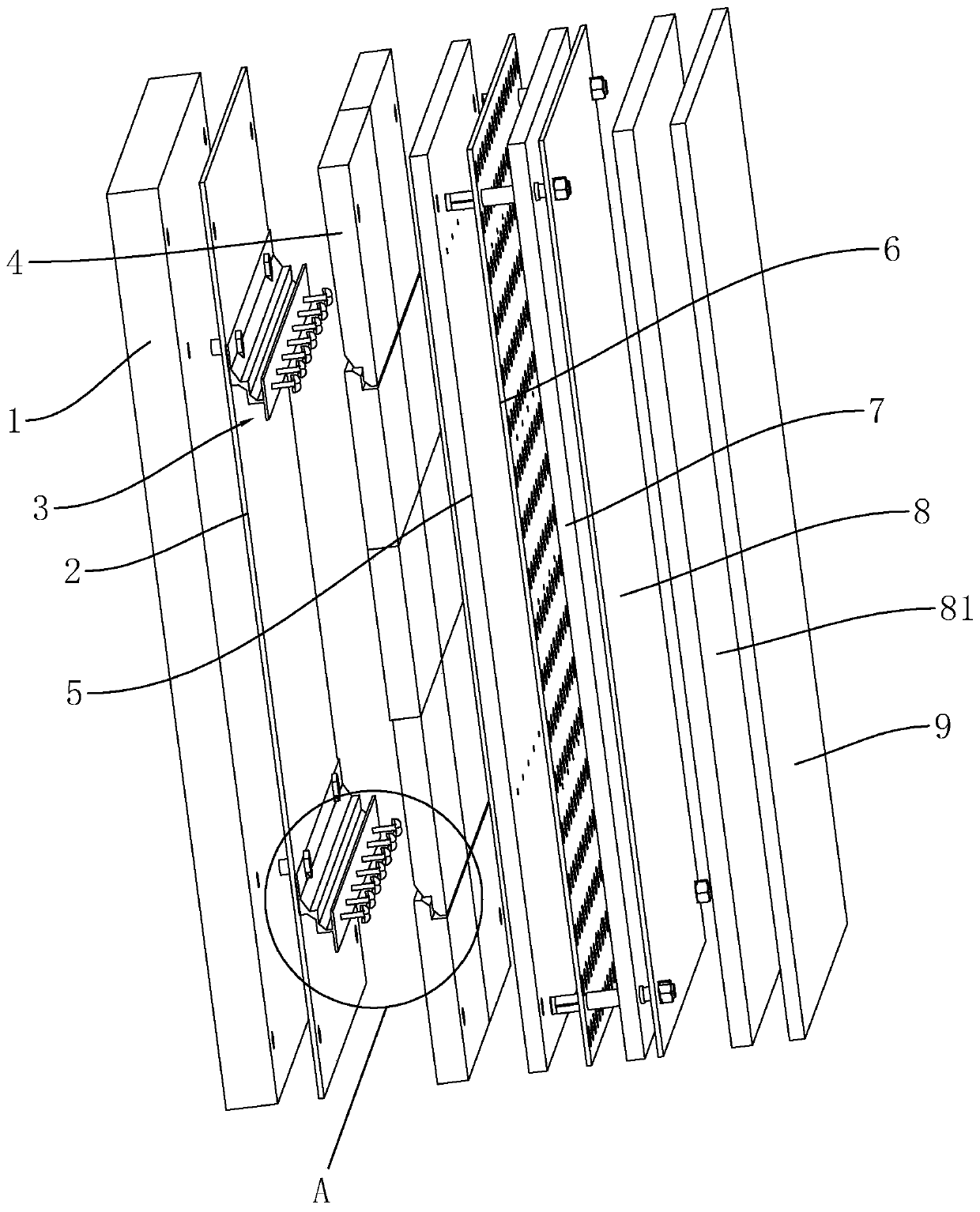

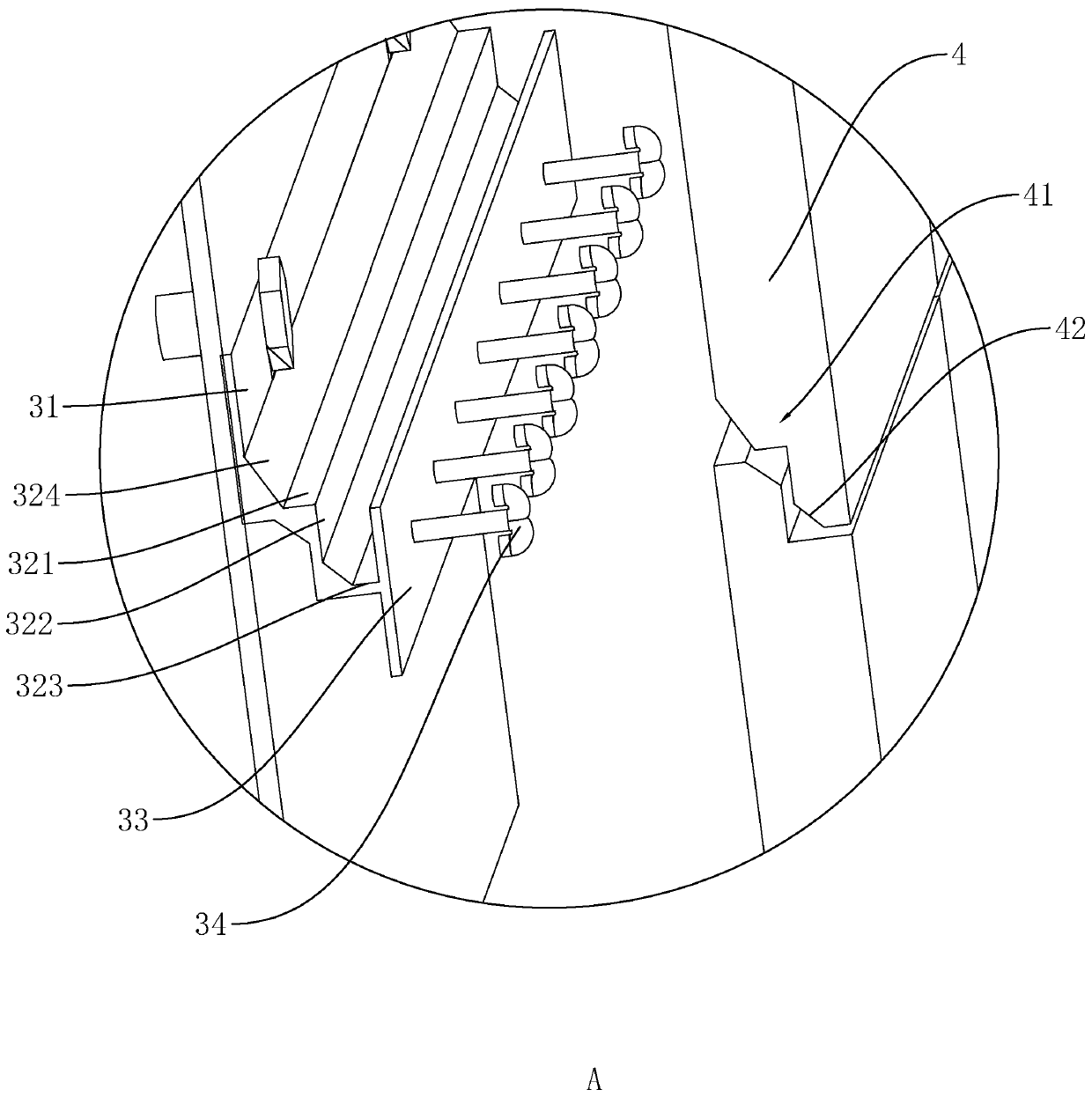

[0040] S1, refer to figure 1 , clean the oil stains, floating ash, etc. on the surface of the outer wall 1, clean the surface of the outer wall 1, remove the loose and weathered parts of the outer wall 1, apply a layer of leveling layer 2 on the outer wall of the outer wall 1, and apply a leveling layer on the leveling layer 2 pops up and installs the horizontal line of every layer of insulation board 4, thereby is the reference datum line when insulation board 4 is installed, guarantees the verticality and flatness when insulation board 4 is installed. Leveling layer 2 is made by mixing cement and sand in a ratio of 1:3.

[0041] S2, refer to figure 1Each three-layer insulation board 4 on the outer wall 1 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com