A method for constructing rammed earth walls with square steel pipe columns and steel bars

A construction method and technology of square steel pipes, which are applied in building structures, walls, building components, etc., can solve problems such as constraints, difficulty in meeting the improvement of living quality and house safety, improve integrity and stability, and improve horizontal resistance. Effect of shear capacity and safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

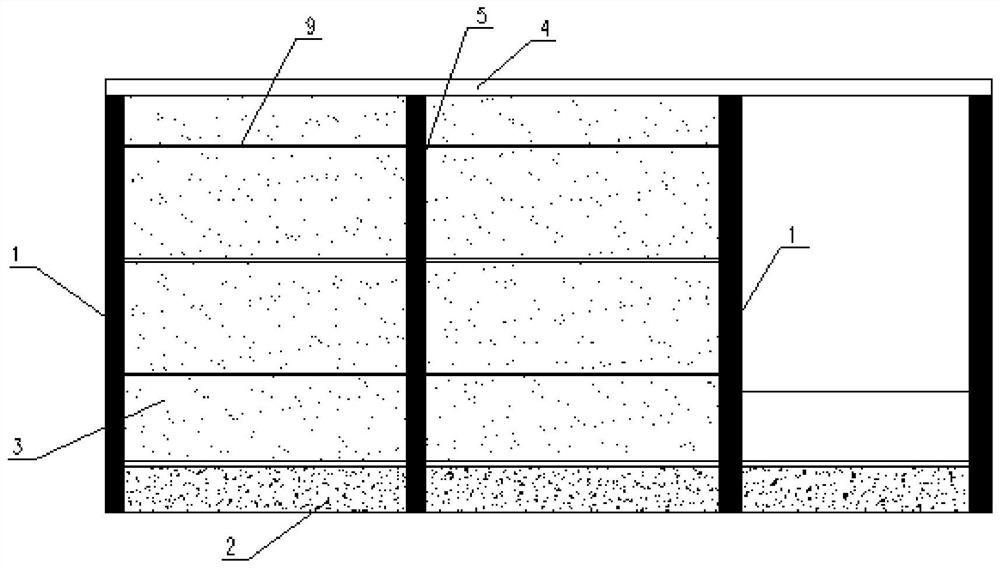

[0064] S1, select the size of the square steel pipe according to the thickness of the wall, and pre-embed the square steel pipe on the foot or a reliable foundation. The distance between the structural columns of square steel pipes along the length direction of the wall is 3000mm; the width of the structural columns of galvanized square steel pipes is 200mm;

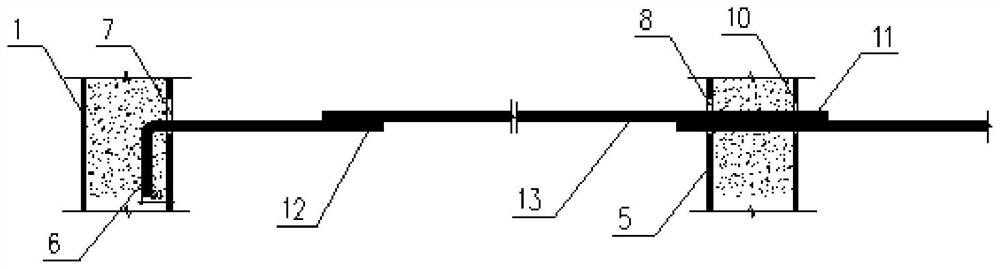

[0065] S2, when the rammed earth wall is rammed to the position of the horizontal steel bar, the end of the horizontal tie steel bar adopts a 90-degree hook straight section of 180mm. The diameter of the horizontal tie bars of the rammed earth wall is 18mm, and the spacing is 1400mm; the straight section of the hook is 160mm.

[0066] The steel bars between the two structural columns are overlapped with a length of 120mm and welded.

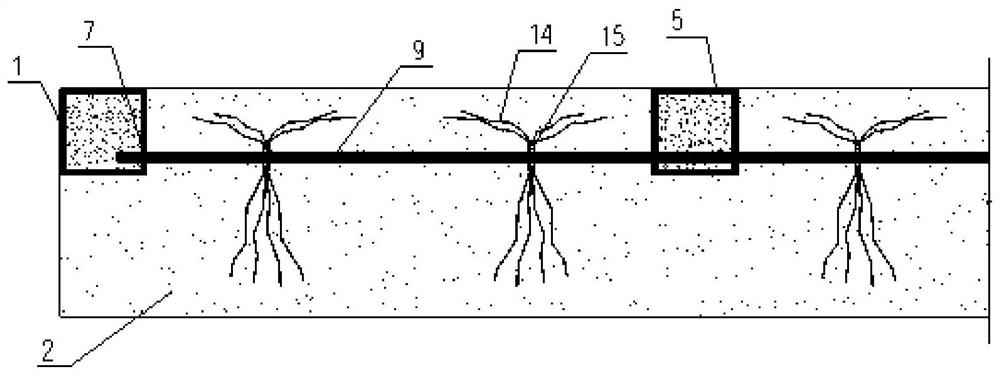

[0067] S3, the wire claws are 80mm away from the surface of the rammed earth wall, and the distance is 400mm.

[0068] The claws are tied by galvanized iron wires. The galvanized iron wir...

Embodiment 2

[0070] S1, select the size of the square steel pipe according to the thickness of the wall, and pre-embed the square steel pipe on the foot or a reliable foundation. The distance between the structural columns of square steel pipes along the length direction of the wall is 2000mm; the width of the structural columns of galvanized square steel pipes is 300mm;

[0071] S2, when the rammed earth wall is rammed to the position of the horizontal steel bar, the end of the horizontal tie steel bar adopts a 90-degree hook straight section of 200mm. The diameter of the horizontal tie bars of the rammed earth wall is 16mm, and the spacing is 1200mm; the straight section of the hook is 180mm.

[0072] The steel bars between the two structural columns are overlapped with a length of 160mm and welded.

[0073] S3, the wire claws are 60mm away from the surface of the rammed earth wall, and the distance is 300mm.

[0074] The claws are tied by galvanized iron wires. The galvanized iron wir...

Embodiment 3

[0076] S1, select the size of the square steel pipe according to the thickness of the wall, and pre-embed the square steel pipe on the foot or a reliable foundation. The distance between the structural columns of square steel pipes along the length direction of the wall is 1500mm; the width of the structural columns of galvanized square steel pipes is 300mm;

[0077] S2, when the rammed earth wall is rammed to the position of the horizontal steel bar, the end of the horizontal tie steel bar adopts a 90-degree hook straight section of 200mm. The diameter of the horizontal tie bars of the rammed earth wall is 16mm, and the spacing is 1000mm; the straight section of the hook is 200mm.

[0078] The steel bars between the two structural columns are overlapped with a length of 150mm and welded.

[0079] S3, the wire claws are 100mm away from the surface of the rammed earth wall, and the distance is 300mm.

[0080] The claws are tied by galvanized iron wires. The galvanized iron wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com