High light-efficiency end-face light guide plate for backlight module and preparation process thereof

A technology of backlight module and light guide plate, applied in the direction of light guide, flat/plate light guide, light guide of lighting system, etc., can solve the problems of unreasonable setting of dots, not enough green environmental protection, high toxicity of chloroform, etc., to increase scattered light and mixed light The effect, the uniform effect of light output is good, the effect of increasing the diffusion range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

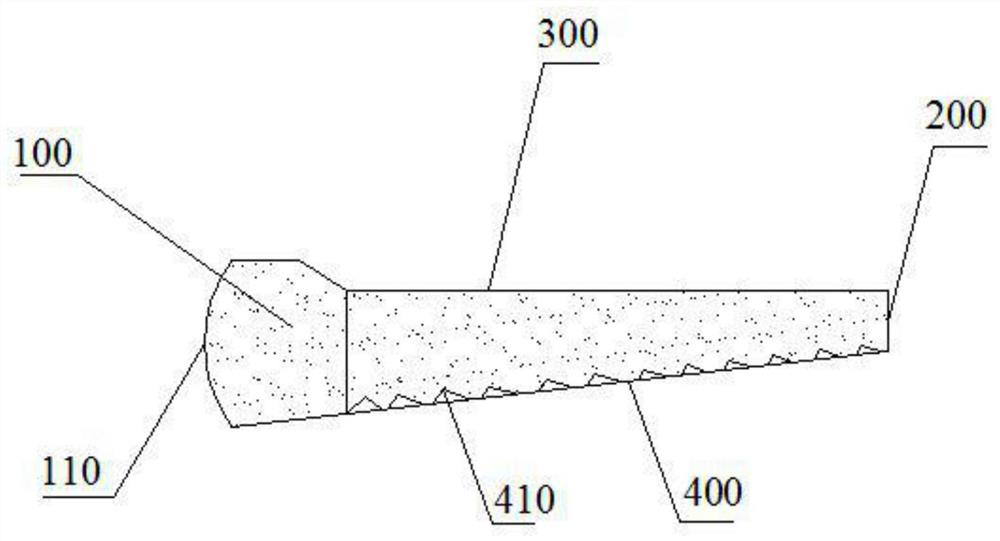

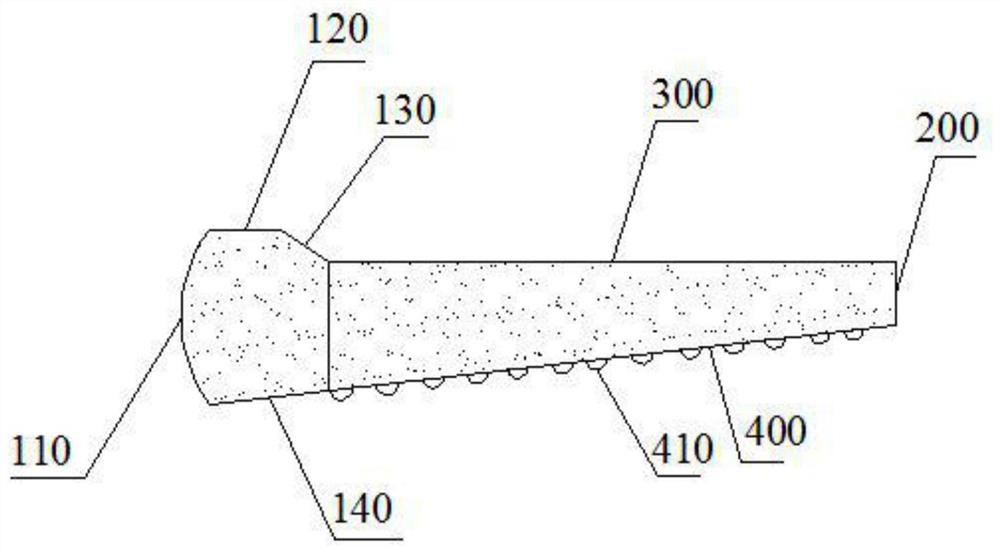

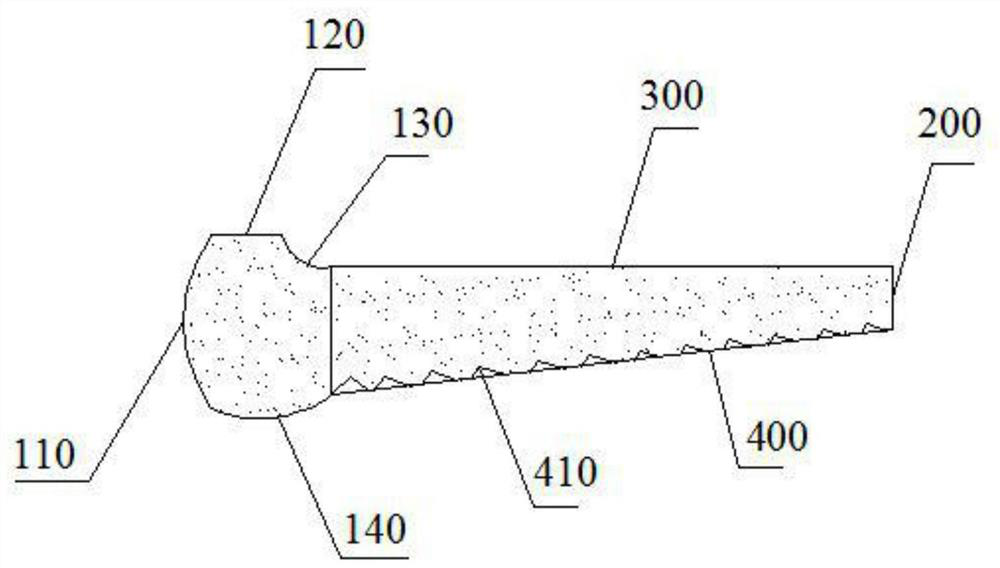

[0035] see Figure 1-5 As shown, this embodiment provides a high-efficiency end-face light guide plate for a backlight module, including a light incident surface 100, a light guide end surface 200 opposite to the light incident surface 100, and a connection between the light incident surface 100 and the light guide end surface 200. The light exit surface 300 is connected to the light incident surface 100 and the light guide surface 400 of the light guide end surface 200 . The light emitting surface 300 is horizontal, the light guiding end surface 200 is vertical, and the light guiding surface 400 is oblique.

[0036]Specifically, the light incident surface 100 includes an upper surface, a lower surface 140, and a light incident end surface 110, one end of the light incident end surface 110 is connected to the upper surface, and the other end is connected to the lower surface 140; the other end of the upper surface is connected to the light exit surface 300, The other end of t...

Embodiment 2

[0040] The high-efficiency end-surface light guide plate for a backlight module of this embodiment is suitable for a backlight module. refer to Figure 5 As shown, in addition to the light guide plate 1, the backlight module also includes a back plate 2, a reflective sheet 3 disposed on the back plate 2, an LED light source 4 disposed on the side wall of the back plate 2, and a light source disposed on the light guide plate 1. The optical film group is arranged on the plastic frame 5 on both sides of the back plate 2 . The LED light source 4 corresponds to the light incident surface of the light guide plate 1 , and the optical film set includes an upper diffusion sheet 6 , a prism sheet 7 , and a lower diffusion sheet 8 arranged in sequence from top to bottom. The working process of the backlight module is as follows: turn on the LED light source 4, the LED light source is a line light source, the light emitted enters from the light incident surface of the light guide plate 1...

Embodiment 3

[0042] This embodiment provides a preparation process of a high-efficiency end-face light guide plate for a backlight module, including the following steps:

[0043] S1. Light guide plate mold preparation: Design the light guide plate mold according to the light guide plate to be produced. The light guide plate mold is a hollow structure composed of a light entrance mold surface, a light exit mold surface, a light guide mold surface, and a light guide end mold surface. An injection port is provided on the end mold surface, and the light entrance mold surface, the light exit mold surface, the light guide mold surface, and the light guide end mold surface correspond to the light entrance surface 100, the light exit surface 300, the light guide surface 400, and the light guide end surface 200, respectively. The surface of the light guide mold is provided with a convex mold surface corresponding to the protrusion 410; wherein, the thickness of the light guide plate mold is 5-10mm, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com