Electromagnet coil winding machine

An electromagnet coil and winding machine technology, applied in coil manufacturing, inductor/transformer/magnet manufacturing, circuits, etc., can solve the problem of disorderly winding, unable to achieve multi-layer precision winding, and unable to meet the space of individual coils requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to more fully explain the implementation of the present invention, implementation examples of the present invention are provided. These implementation examples are only illustrations of the present invention, and do not limit the scope of the present invention.

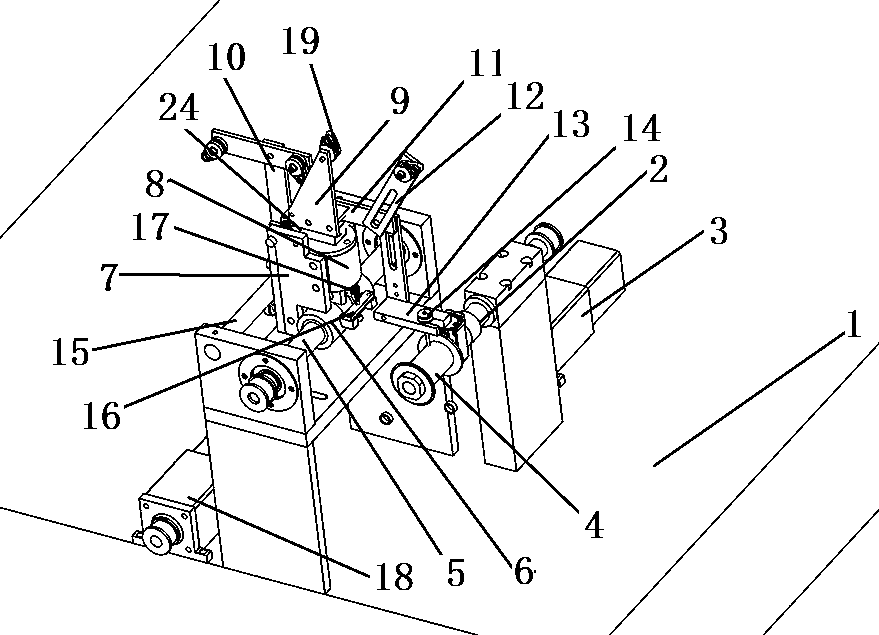

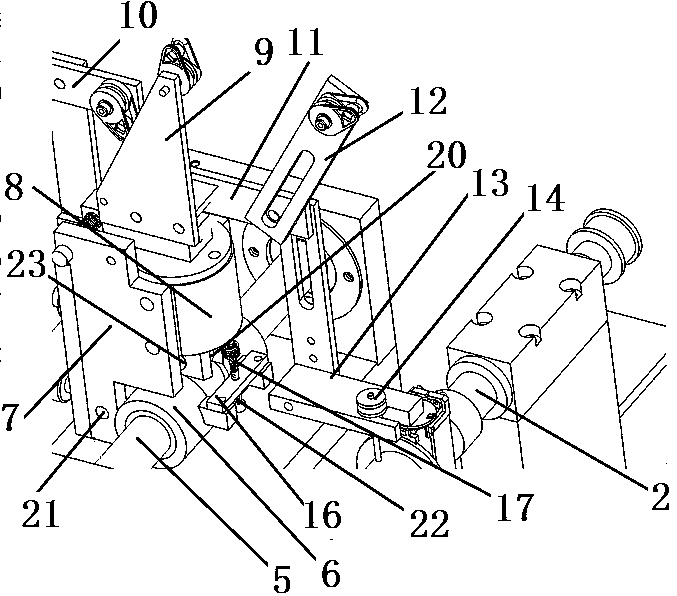

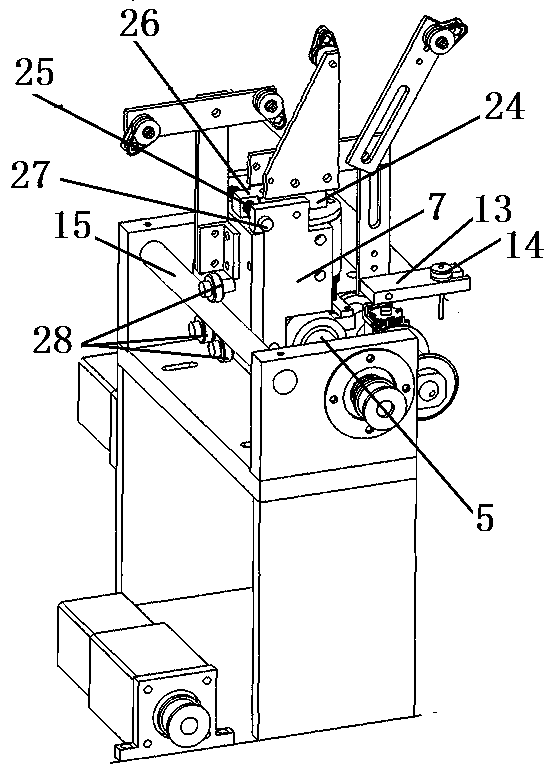

[0016] A further detailed explanation of the present invention is given in conjunction with the accompanying drawings. Each label in the accompanying drawings is: 1: frame; 2: main shaft; 3: main shaft motor; 4: bobbin; 5: optical axis; 6: sliding sleeve; 7: groove 8: Bearing sleeve; 9: Wire arm A; 10: Wire arm B; 11: Inverted L-shaped bracket; 12: Wire arm C; 13: Guide needle seat; 14: Hollow guide needle; 15: Positioning rod; 16 : Lower plate; 17: Adjusting spring; 18: Optical axis motor; 19: Anti-jumper; 20: Spherical bearing; 21: Pin hole B; 22: Adjusting bolt; 23: Spherical bearing shaft; 24: Connecting plate; 25 : balance positioning lug; 26: balance spring; 27: balance bolt; 28: guide wheel; 29...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com