Modbus serial communication method for industrial equipment

A technology for serial communication and industrial equipment, applied in the field of industrial equipment service architecture, it can solve the problems of insufficient SlaveID and IP address to identify equipment, occupation, difficult and scalable cloud service mode to connect Modbus equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

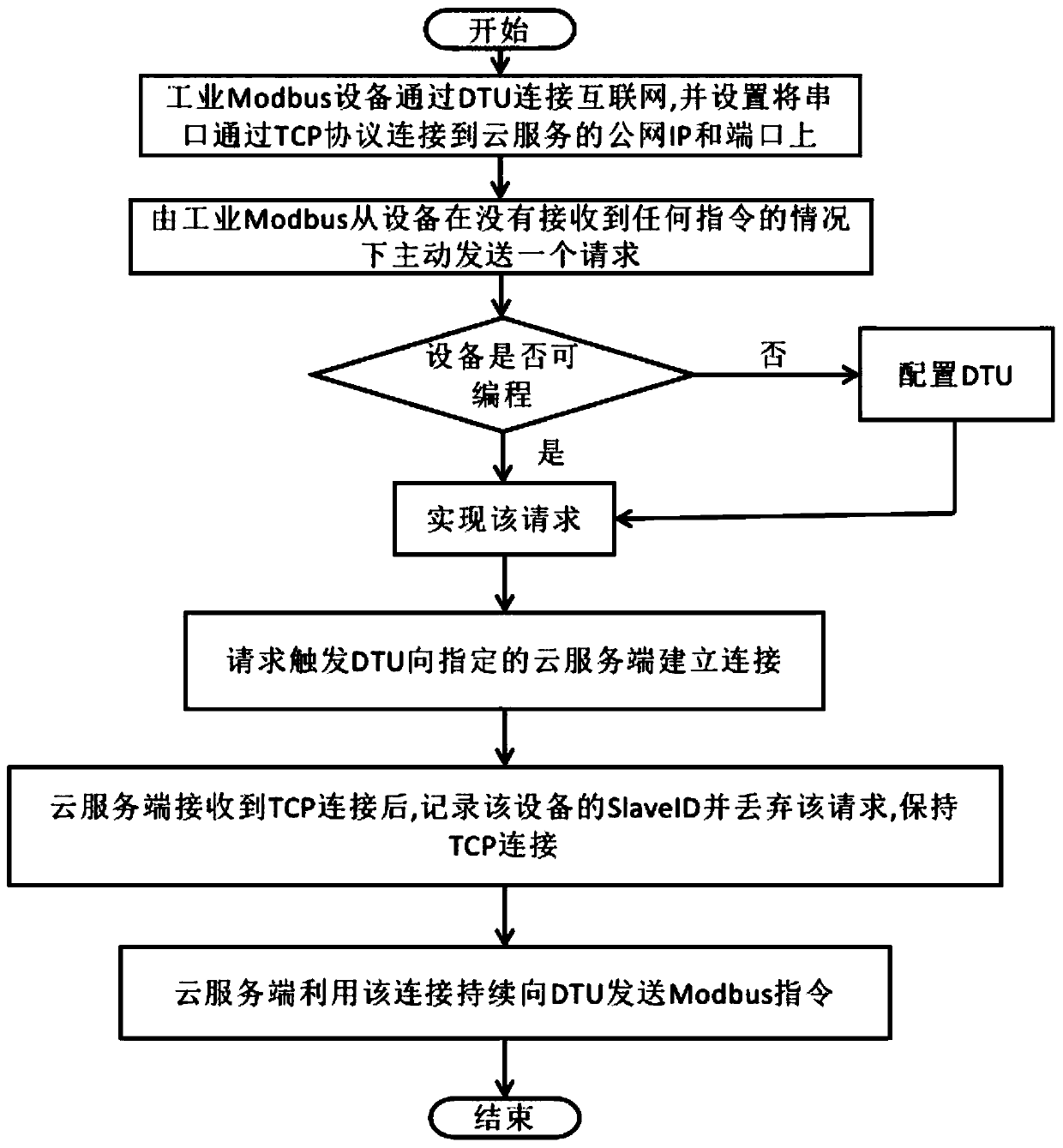

[0022] like figure 1 A method of industrial equipment Modbus serial communication is shown as follows:

[0023] The cloud server runs as a virtual Modbus master device, and exposes an IP address and corresponding port that can be accessed by the public network to receive TCP connections from the slave device, including the following steps;

[0024] S1: The industrial Modbus device is connected to the Internet through the DTU, and the serial port is connected to the public network IP and port of the cloud service through the TCP protocol;

[0025] S2: Send connection request: The industrial Modbus slave device actively sends a request without receiving any instructions. If the slave device is programmable, the request is realized by a program running on the device; if the slave device is not programmable Yes, implement the request through DTU configuration;

[0026] S3: Establish initial connection:

[0027] S3.1: the request described in the step S2 triggers the DTU to esta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com