Transport cart for chemical production raw materials

A technology of transport vehicles and raw materials, applied in the field of transport vehicles, can solve the problems of inability to separate and transport raw materials for chemical production, unfavorable use of staff, poor shock absorption effect, etc., and achieve the effects of easy maintenance and repair, good shock absorption effect, and convenient movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

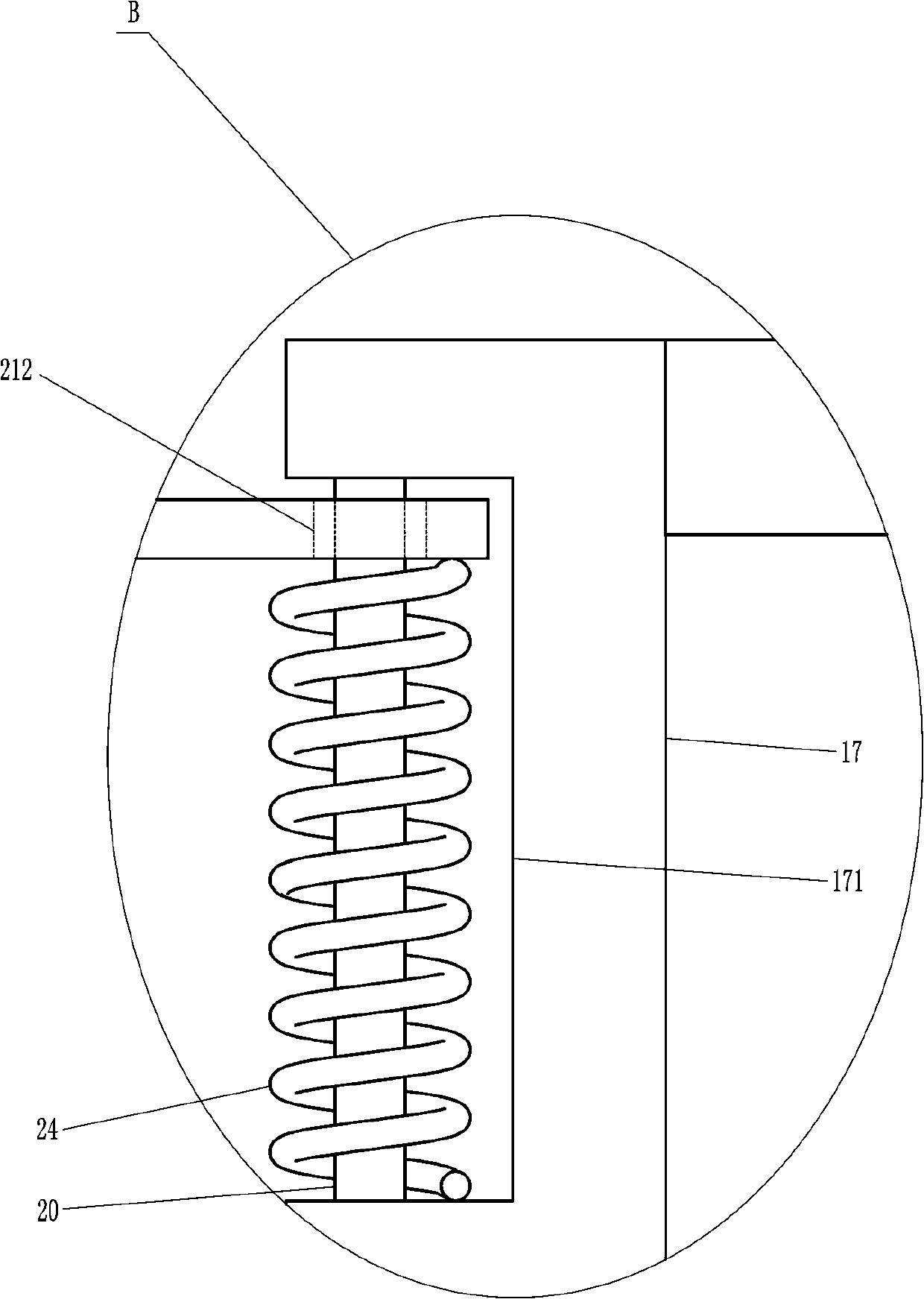

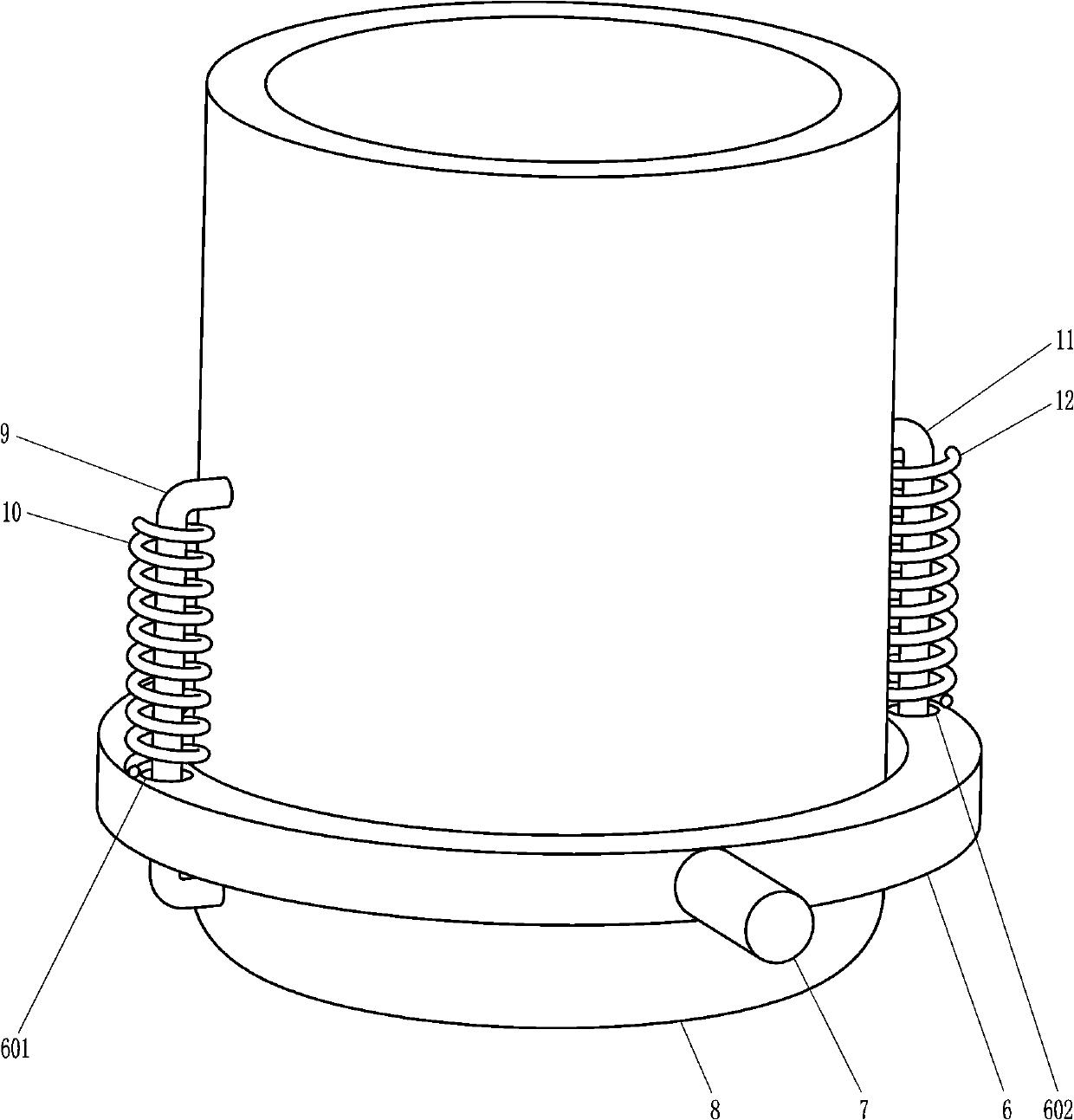

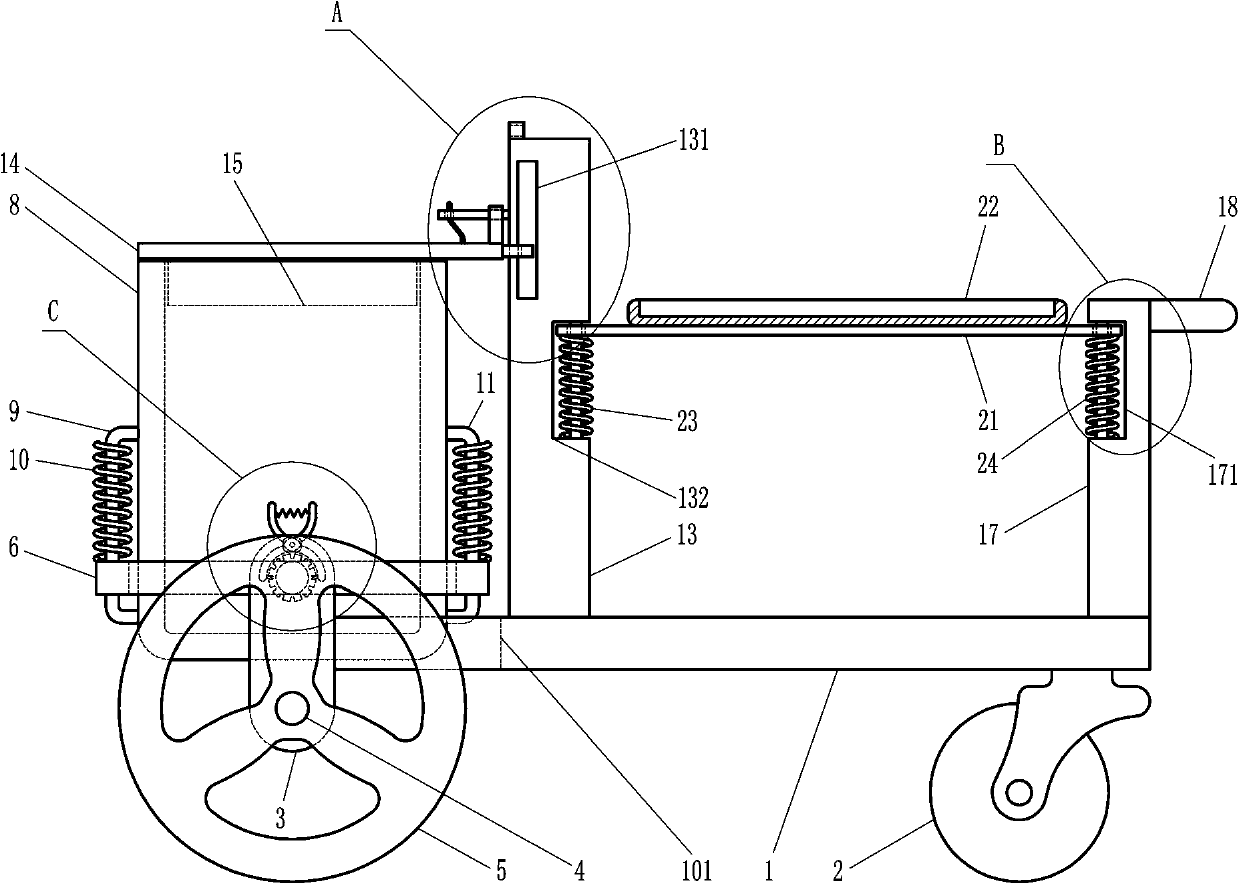

[0021] A production raw material transport vehicle for chemical industry, such as Figure 1-5As shown, it includes a base 1, a universal wheel 2, a large fixed plate 3, a first connecting shaft 4, a roller 5, a large ring 6, a second connecting shaft 7, a cylinder body 8, a first U-shaped rod 9, First large spring 10, second U-shaped rod 11, second large spring 12, large bracket 13, cover plate 14, plunger 15, concave sliding sleeve 16, small bracket 17, U-shaped push rod 18, first guide Rod 19 and second guide rod 20, the right side of base 1 bottom is connected with universal wheel 2, and the left side of base 1 is connected with large fixed plate 3, and large fixed plate 3 is arranged symmetrically before and after, the base 1 The left side wall is provided with a large groove 101, and the large groove 101 is located between the large fixed plates 3 arranged symmetrically before and after. The roller 5 is connected, the first connecting shaft 4 and the roller 5 are arrange...

Embodiment 2

[0023] A production raw material transport vehicle for chemical industry, such as Figure 1-5 As shown, it includes a base 1, a universal wheel 2, a large fixed plate 3, a first connecting shaft 4, a roller 5, a large ring 6, a second connecting shaft 7, a cylinder body 8, a first U-shaped rod 9, First large spring 10, second U-shaped rod 11, second large spring 12, large bracket 13, cover plate 14, plunger 15, concave sliding sleeve 16, small bracket 17, U-shaped push rod 18, first guide Rod 19 and second guide rod 20, the right side of base 1 bottom is connected with universal wheel 2, and the left side of base 1 is connected with large fixed plate 3, and large fixed plate 3 is arranged symmetrically before and after, the base 1 The left side wall is provided with a large groove 101, and the large groove 101 is located between the large fixed plates 3 arranged symmetrically before and after. The roller 5 is connected, the first connecting shaft 4 and the roller 5 are arrang...

Embodiment 3

[0026] A production raw material transport vehicle for chemical industry, such as Figure 1-5 As shown, it includes a base 1, a universal wheel 2, a large fixed plate 3, a first connecting shaft 4, a roller 5, a large ring 6, a second connecting shaft 7, a cylinder body 8, a first U-shaped rod 9, First large spring 10, second U-shaped rod 11, second large spring 12, large bracket 13, cover plate 14, plunger 15, concave sliding sleeve 16, small bracket 17, U-shaped push rod 18, first guide Rod 19 and second guide rod 20, the right side of base 1 bottom is connected with universal wheel 2, and the left side of base 1 is connected with large fixed plate 3, and large fixed plate 3 is arranged symmetrically before and after, the base 1 The left side wall is provided with a large groove 101, and the large groove 101 is located between the large fixed plates 3 arranged symmetrically before and after. The roller 5 is connected, the first connecting shaft 4 and the roller 5 are arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com