Agile quadruped robot based on coaxial parallel mechanism

A quadruped robot, parallel technology, used in motor vehicles, transportation and packaging, etc., can solve the problems of inflexibility, lightness, limited rotation angle, and many motors, and achieve excellent power performance, high reliability, and leg rotation. big moment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

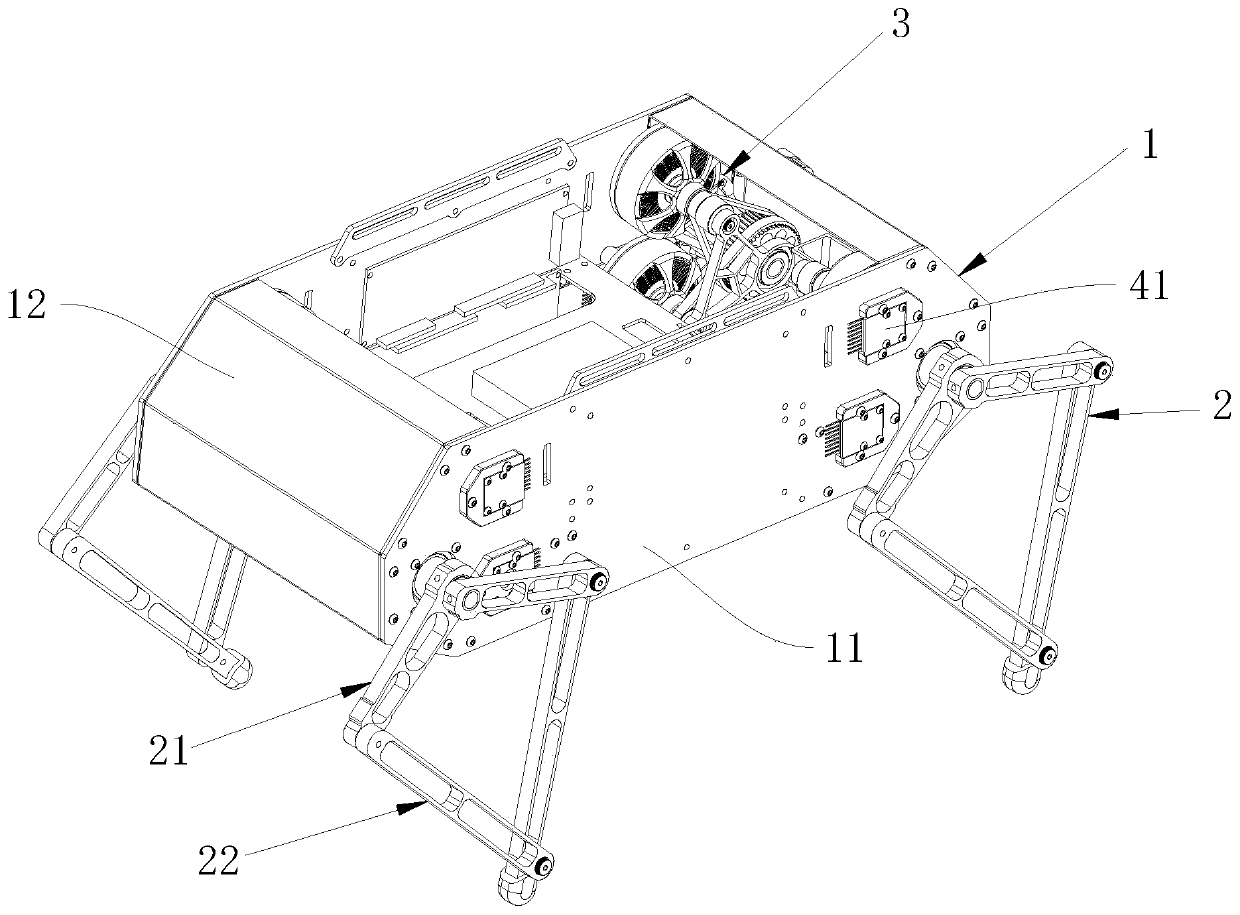

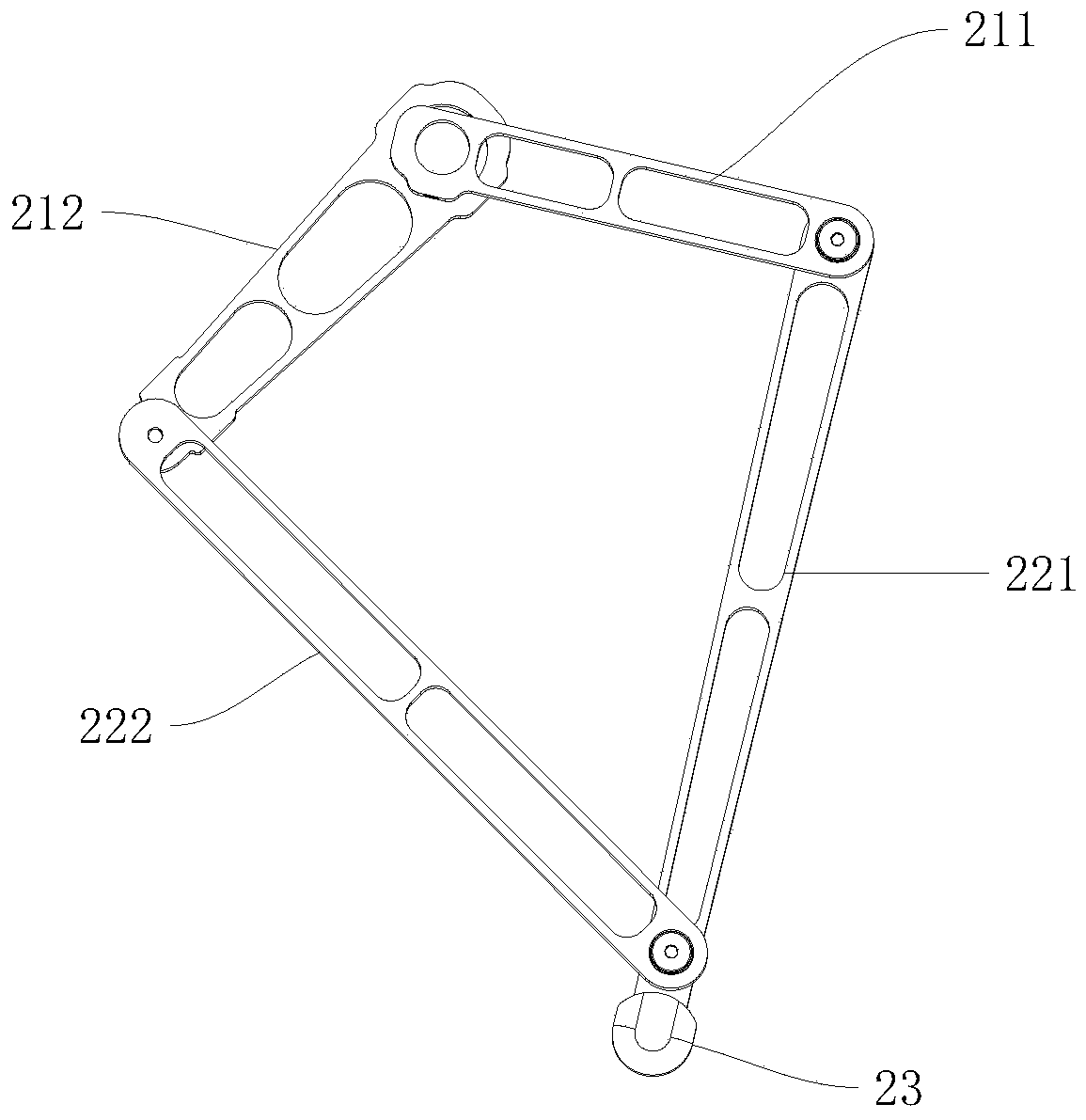

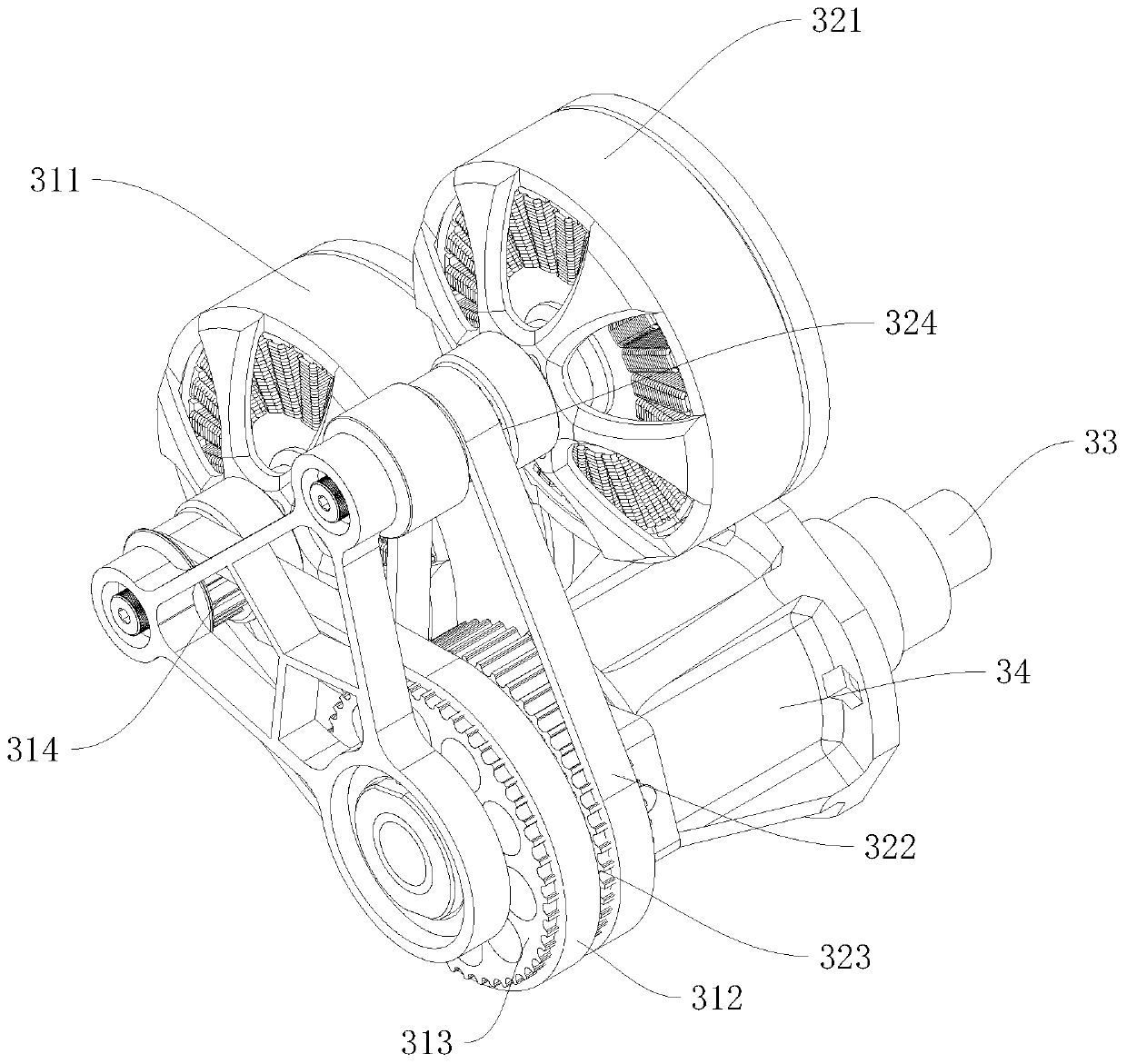

[0022] Such as figure 1 As shown, an agile quadruped robot based on a coaxial parallel mechanism includes a torso 1, four parallel legs 2, a dual-motor coaxial asynchronous transmission module 3 for driving the parallel legs 2 in the torso 1, and a control With communication module and power module. The control and communication module is mainly used to control the operation of the dual-motor coaxial asynchronous transmission module 3 and to control the gait of the whole legged robot, and the power module is used to supply power to the whole robot.

[0023] The torso 1 includes the torso side plates 11 arranged on both sides of the torso 1, the torso fixed bent plates 12 arranged at both ends of the torso 1 in the front and rear directions, and the torso fixed bottom plate arranged at the bottom of the torso 1, the torso side plates 11, the torso fixed bent plates 12 and The edges of the fixed base plate of the torso are connected and fixedly combined to form an integral tors...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com