Blade-free stacking machine and process thereof

A stacker and blade technology, applied in the field of bladeless stacker and its process, can solve the problems of high labor intensity, high failure rate and high cost, and achieve the effect of reducing labor intensity, reducing cost input and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

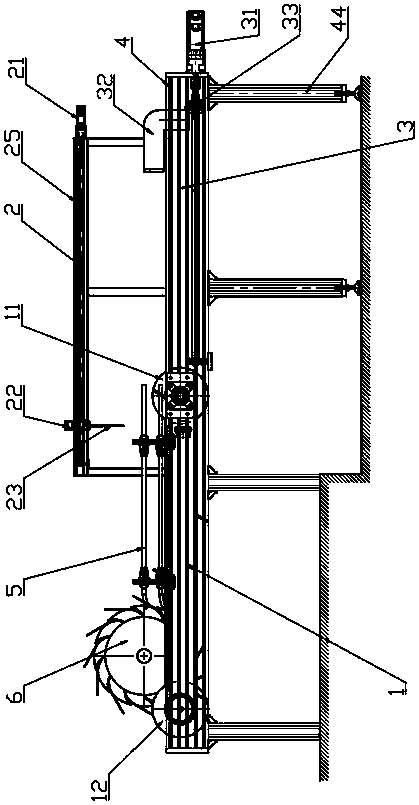

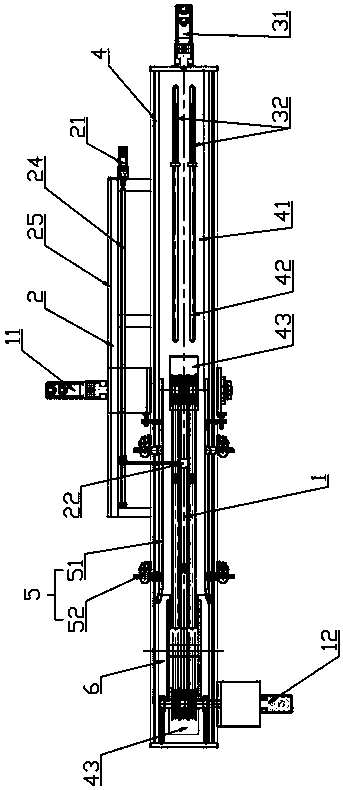

[0041] A bladeless palletizer, used to connect the hot wheels 6 at the end of the production equipment of sanitary products 7 (such as disposable sanitary products adult diapers, disposable baby diapers, disposable nursing pads, etc.) for palletizing and packaging, including the main frame 4. A height-adjustable support leg 44 is provided under the main frame 4 to facilitate the adjustment of the height of the main frame 4, so that the connection with other equipment is more reasonable; the main frame 4 is provided with various control The control system of the driving device, the main frame 4 is provided with a stacking device 1, a stacking device 2 and a stacking device 3;

[0042] The palletizing device 1 may have multiple conveying components for coordinated work, and the number of conveying belts is flexible and variable, and there are multiple combinations of configurations. In this embodiment, three conveying belts are used as an example to describe the related structure an...

Embodiment approach 2

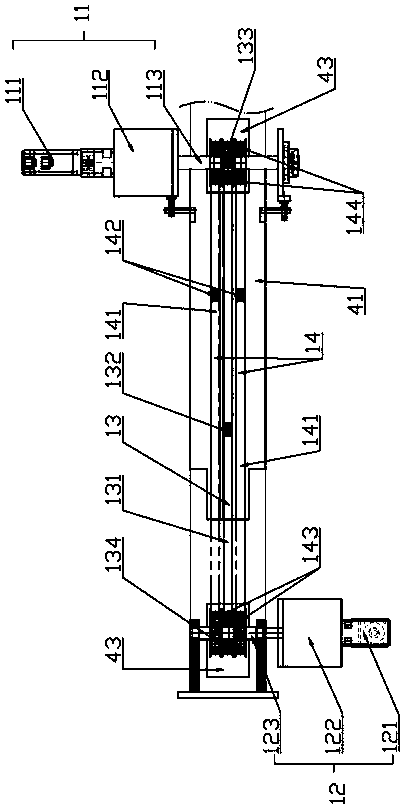

[0062] Such as Figure 11 to Figure 13 As shown, this embodiment works with the structure in which the discharge end of the sanitary product equipment is a feeding belt 8. The feeding belt 8 is conveyed by two compact and vertical belts, and the sanitary products 7 are continuously and rapidly output from the middle. This embodiment The structure of the palletizing device 1 is the same as that of the first embodiment, but the conveying direction is perpendicular to the discharging direction of the sanitary products 7. The conveyor belt assembly of the structure of this embodiment also has a variety of combination configurations. This embodiment uses 6 conveyor belts. An annular slide rail 16 is taken as an example to illustrate the related structure and function. In this embodiment, the discharging position of the sanitary product 7 is provided with the twister 9 directly opposite to the discharging position, so that the sanitary product 7 can fall to the place after being disch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com