Cotton swab collector with induction function

A technology of collectors and cotton swabs, applied in the field of cotton swab collectors, can solve problems such as cross-infection, inconvenient operation, and medical pollution, and achieve the effects of reducing the risk of bacterial infection, facilitating cleaning, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

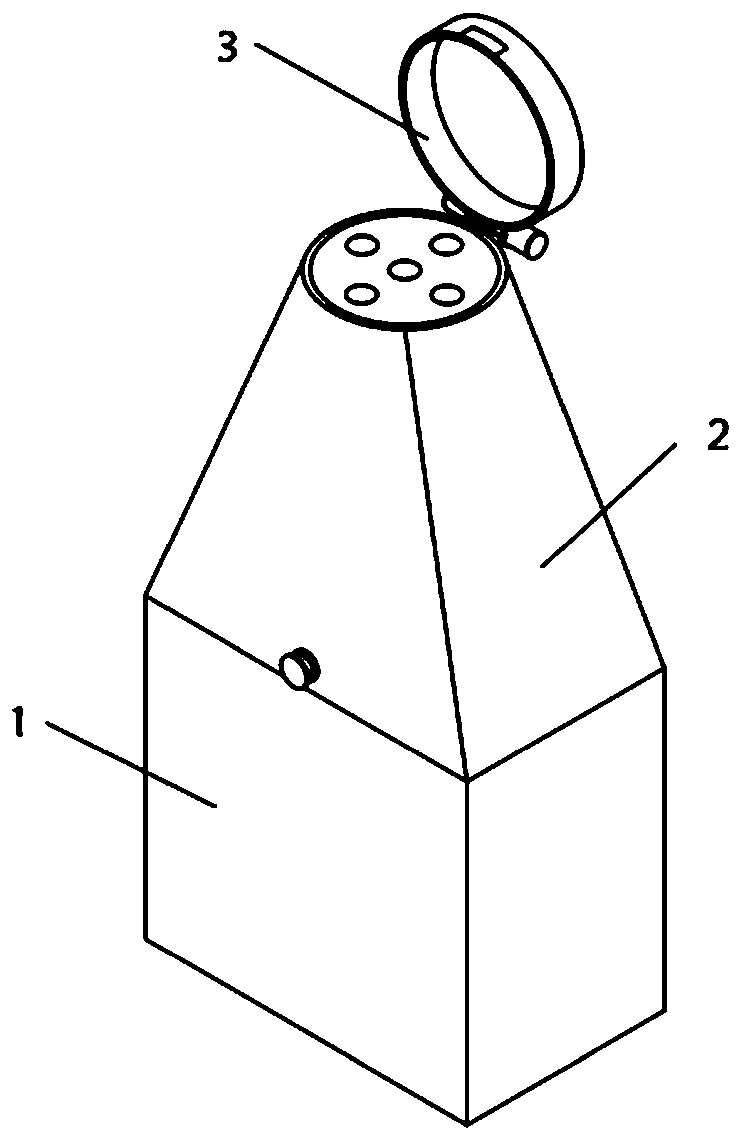

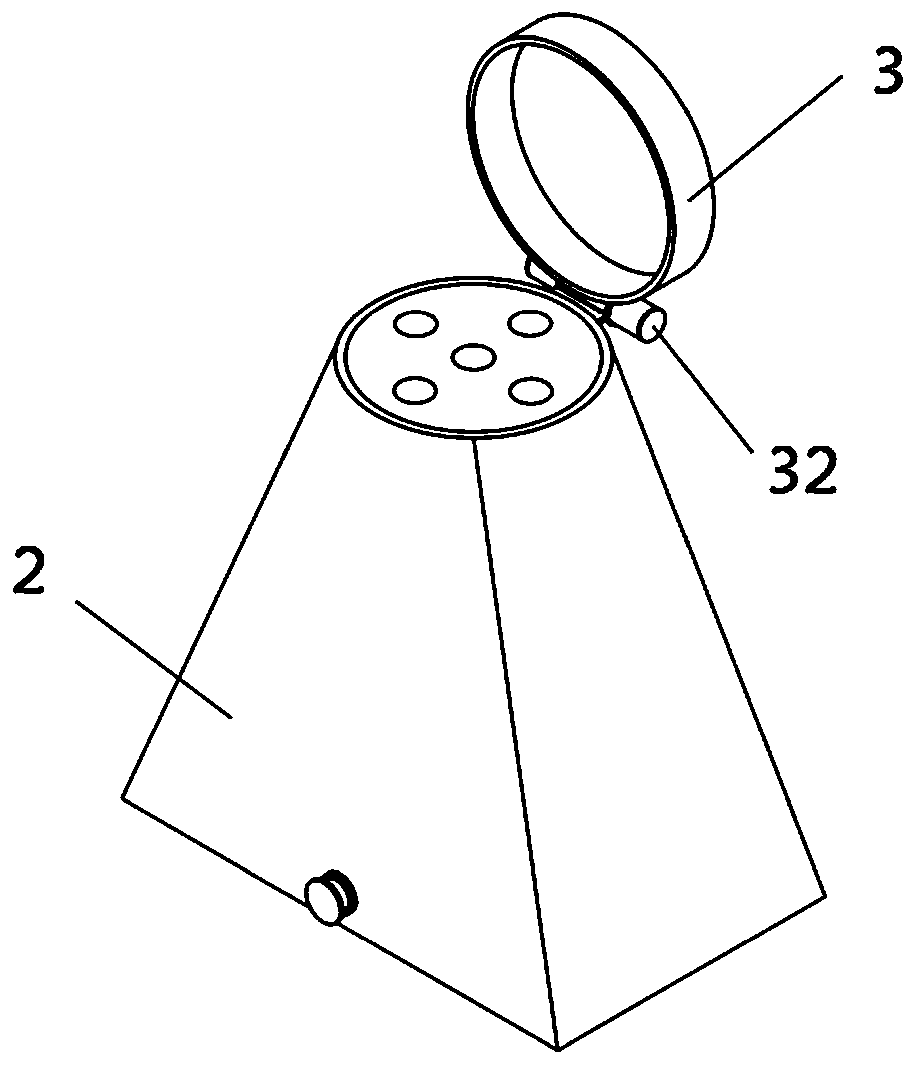

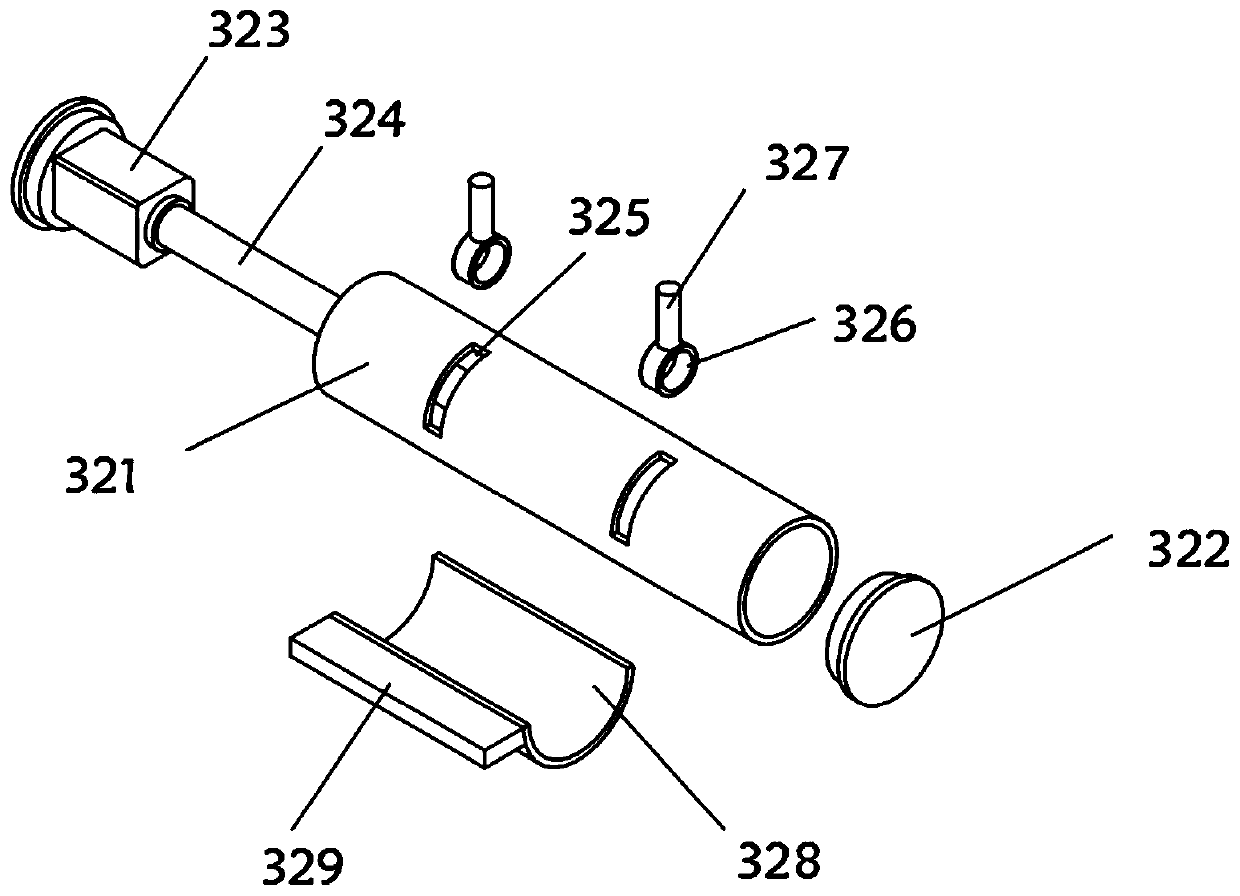

[0048] In one aspect, the present invention provides a cotton swab collector with sensing function, such as Figure 1-Figure 3 As shown, it includes a cotton swab storage barrel 1, a cotton swab entry barrel 2 installed on the top of the cotton swab storage barrel 1, and a flip cover 3 arranged on the top of the cotton swab entry barrel 2. The flip cover 3 is rotatably connected to the cotton swab storage barrel 1 through a connector 32. 32 includes an outer cylinder 321, the two ends of the outer cylinder 321 are respectively provided with cover plates 322, and the inner wall of one of the cover plates 322 is equipped with a working motor 323, one end of the working motor 323 is provided with an output shaft 324, and the outer surface of the outer cylinder 321 is provided with A plurality of sliding slots 325 , a plurality of fixing rings 326 are installed on the outer wall of the output shaft 324 , and a mounting rod 327 is installed on the outer wall of the fixing ring 326 ....

Embodiment 2

[0055] As the second embodiment of the present invention, in the specific implementation process, when throwing cotton swabs, the used side cotton swabs in the cotton swab storage bucket 1 will be exposed to the outside world, resulting in cross-infection phenomenon. In view of this, the present invention is also provided with Baffle 4, as a preferred embodiment, such as Figure 4-Figure 6 As shown, the inside of the cotton swab storage bucket 1 is equipped with a baffle plate 4, the baffle plate 4 includes a pair of slide rail plates 41, the slide rail plate 41 is slidingly connected to the moving plate 42, and one end of the slide rail plate 41 is equipped with a transmission box 45, the transmission A pair of drive rollers 451 are arranged inside the box 45, a drive motor 452 is installed on one of the drive rollers 451, a drive rod 453 is installed on the other drive roller 451, and one end of the drive rod 453 is connected to the drive box 45 through a bearing ring 454 in ...

Embodiment 3

[0063] As a third embodiment of the present invention, in order to facilitate dumping of the cotton swabs inside the cotton swab storage bucket 1, the present invention also makes improvements to the cotton swab storage bucket 1, as a preferred embodiment, such as Figure 7-Figure 12 As shown, a pair of connection plates 11 are installed on the top of the inner wall of the cotton swab storage bucket 1. The connection plate 11 includes a bottom plate 111. One end of the bottom plate 111 is vertically provided with a plug-in plate 112. A plurality of chucks 113 are installed on the inner wall of the plug-in plate 112. The chucks 113 Including the bottom tube 1131, the bottom tube 1131 is slidably connected with the block 1132, the first spring 1133 is installed between the block 1132 and the bottom tube 1131, the top of the cotton swab entering the barrel 2 is provided with a top plate 21, and the top of the top plate 21 is provided with multiple A through hole 22, the outer wall...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap