Bagged material hanging basket type vertical conveying method and conveying mechanism thereof

A conveying mechanism and hanging basket technology, which is applied in the direction of conveyors, hoisting devices, hoisting devices, etc., can solve problems such as dust, high labor costs, and high work intensity, and achieve high conveying efficiency, compact and reasonable structure, and high degree of automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

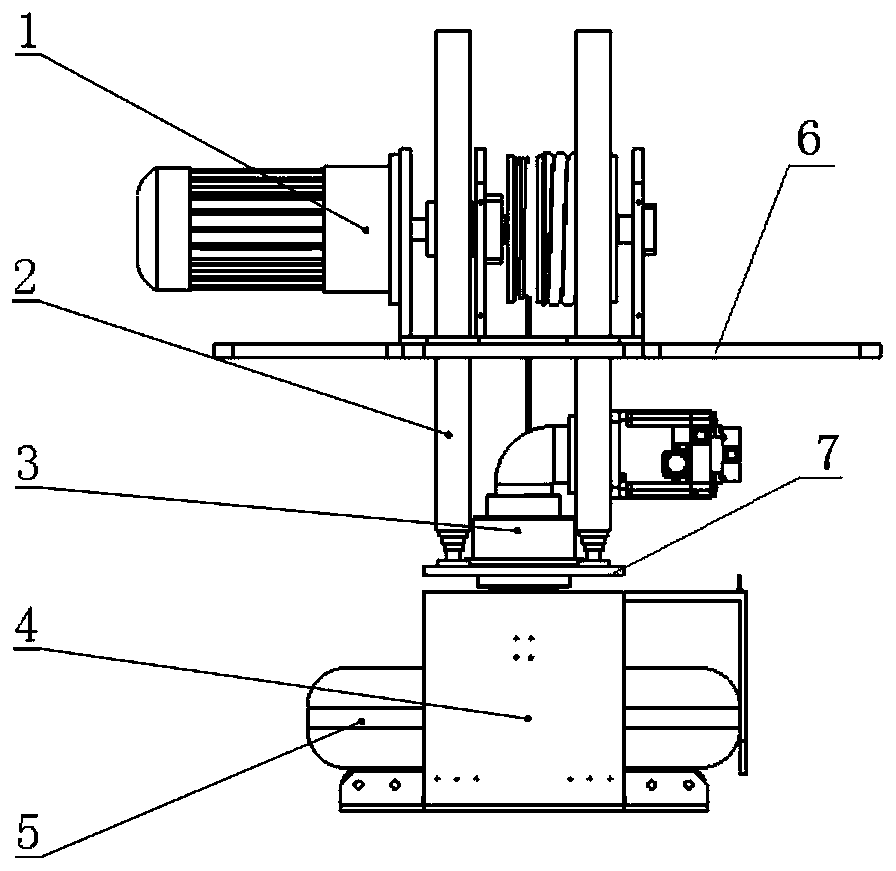

[0031] see Figure 1~6 , the present invention relates to a hanging basket type vertical conveying method for bagged materials, the method is as follows: vertically convey the bagged materials to the top of the designated delivery point through a vertical conveying mechanism; adjust the position of the bagged materials according to the required placement position Put the bagged materials at the designated position after placing the bagged materials; after the bagged materials are placed at the designated position, the vertical conveying mechanism resets and waits for the next batch of bagged materials;

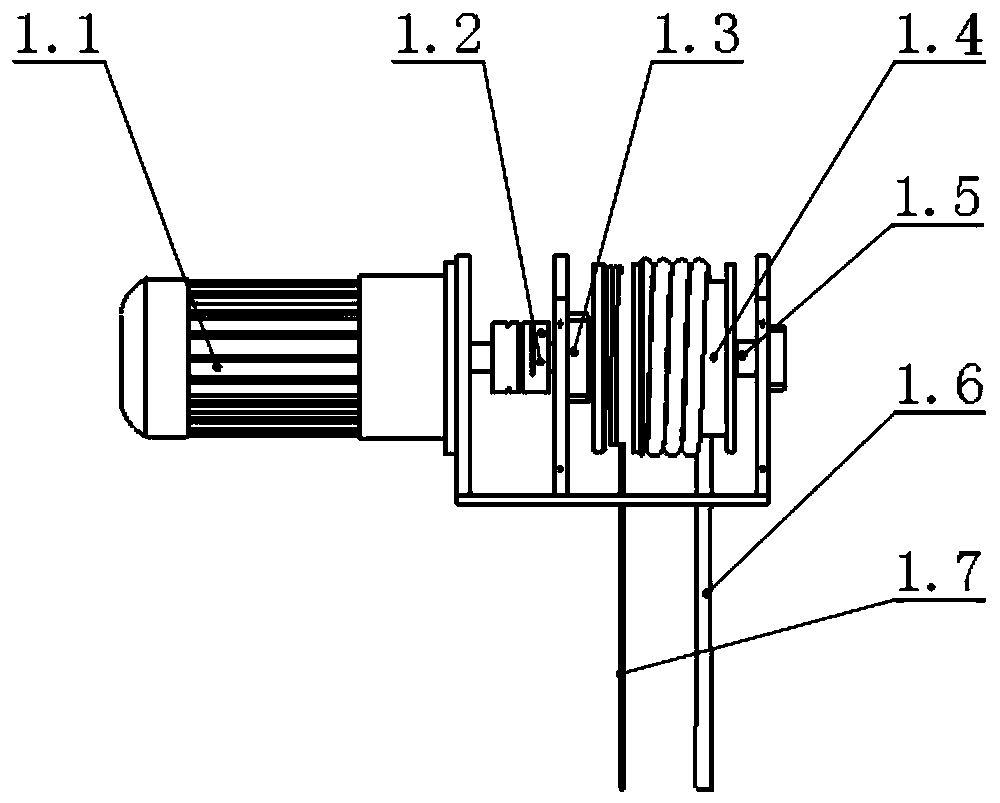

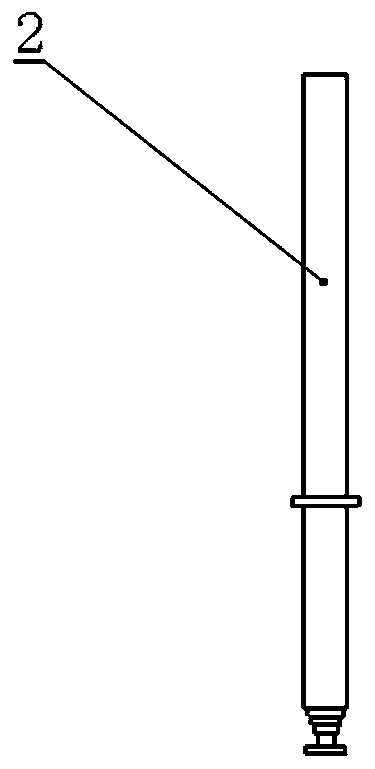

[0032] The above hanging basket type vertical conveying method for bagged materials is realized based on a hanging basket type vertical conveying mechanism for bagged materials. The hanging basket retractable mechanism 1 is fixedly installed on the support frame 6 arranged horizontally, and the hanging basket retractable mechanism 1 is provided with a traction rope 1.7 and is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com