Pretreatment process for obtaining safe, nutritional and good-sensory-quality pressed sunflower seed oil

A sunflower oil and pretreatment technology, applied in the production of fat oil/fat, refining of fat oil/fat, production of fat, etc., can solve the problems of lack, unestablished retention of sunflower shell, and reduce the influence of sensory quality factor content, so as to improve Production efficiency, increased aroma and high sensory quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-13

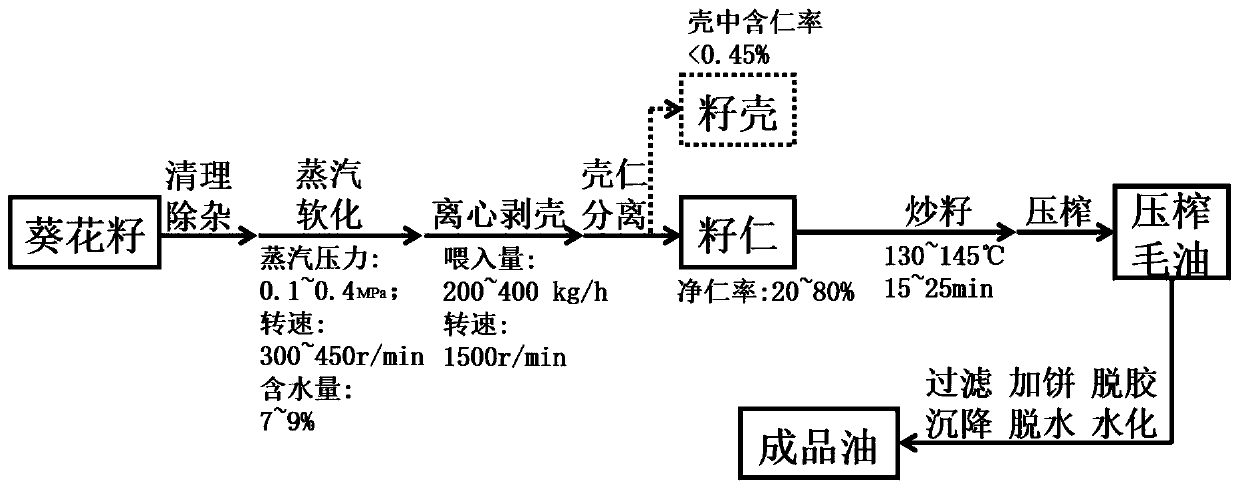

[0057] The manufacture method of the pressed sunflower oil of embodiment 1-13 comprises:

[0058] Step 100: performing a pretreatment process to obtain kernels;

[0059] Step 200: Roasting the seeds, controlling the temperature of the seeds to be 130-160° C., and / or the time to be 15-50 minutes;

[0060] Step 300: pressing to obtain crude oil;

[0061] Step 400: Process the crude oil to obtain finished sunflower oil.

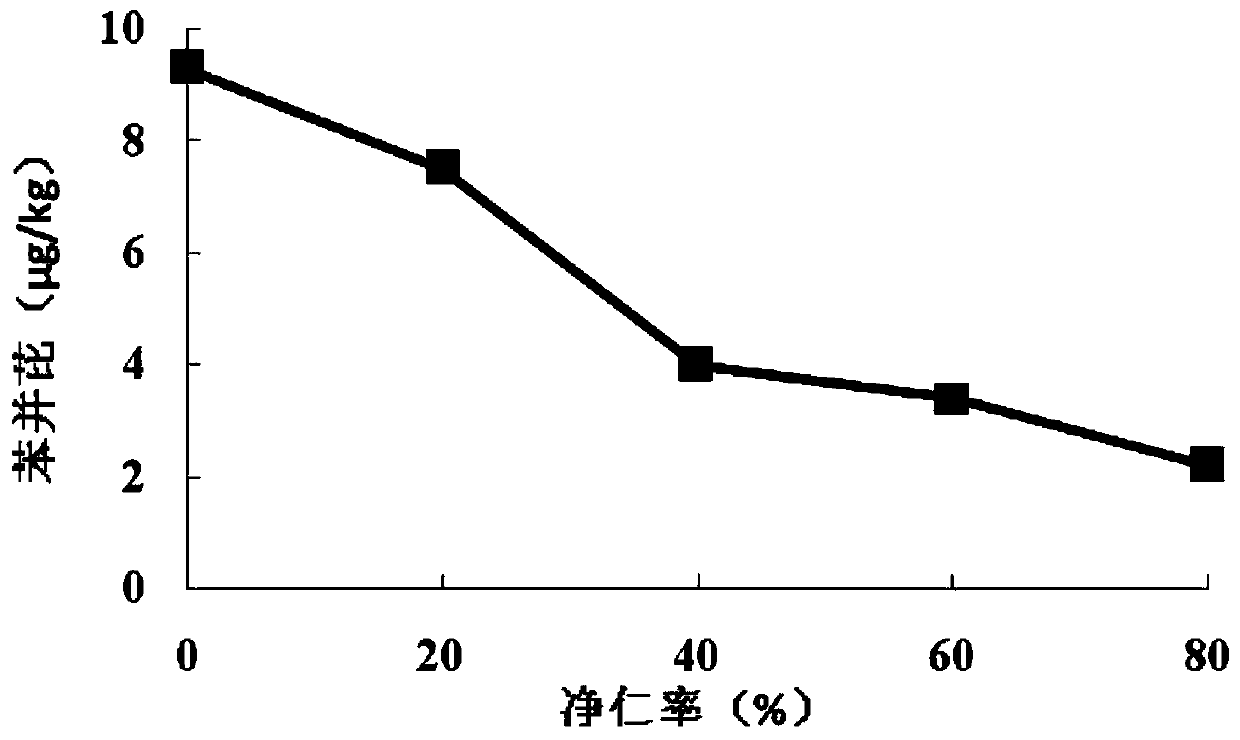

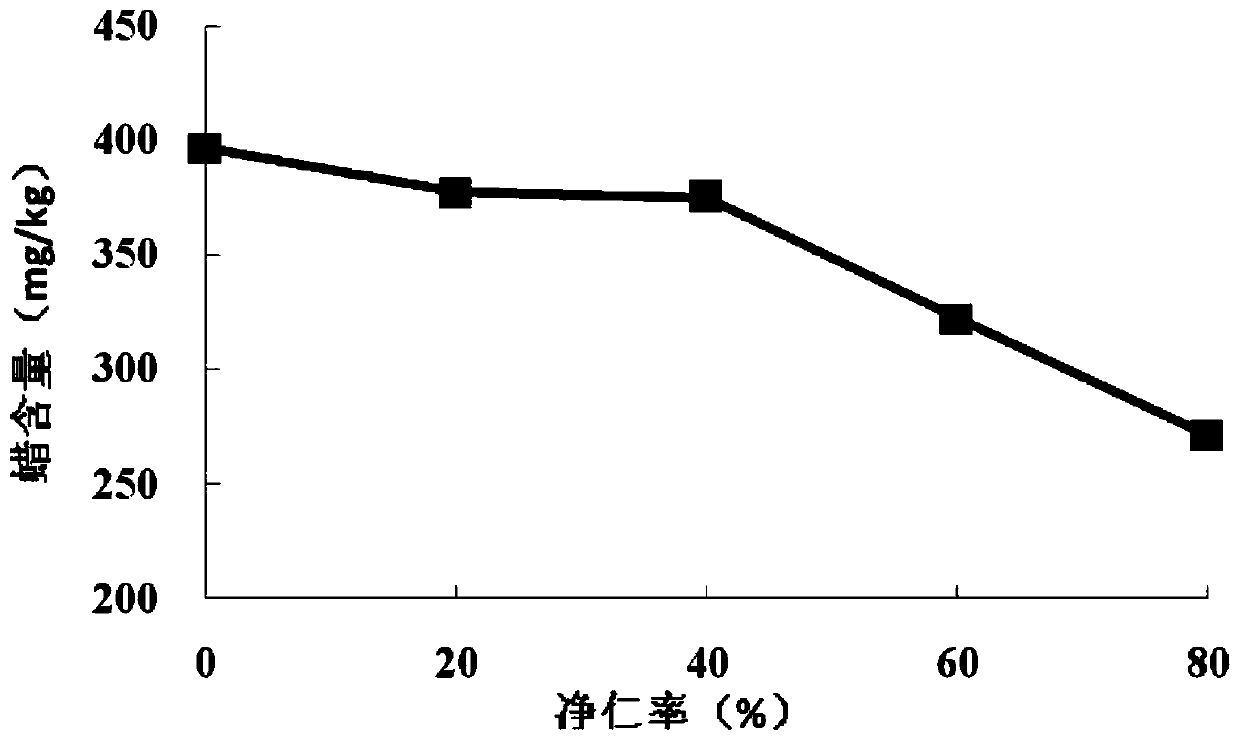

[0062] It should be noted that, in step 100, the pretreatment process includes: shelling the sunflower seeds, and separating the shells and kernels after shelling, so as to obtain the seed shells and the seed shells used as the input material for the pressing step, and the seed shells The net kernel rate is 20-80%, and / or the kernel content rate in the seed shell is <2.5%. During the peeling process, a centrifugal sheller can be used for the shelling process, wherein the shelling process is controlled during the shelling process. When controlling the feeding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com