Feather and down surface finishing method

A surface modification and down technology, used in textiles, papermaking, fiber processing, etc., can solve the problems of poor fiber reaction accessibility, low protein reactivity, poor hydrophilic performance, etc., to achieve improved hydrophilic performance, expanded surface area, The effect of increasing nudity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] For the following, through the description of the examples, the specific implementation of the present invention, such as the manufacturing process involved, the operation and use method, etc., will be described in further detail, so as to help those skilled in the art to have a more complete concept of the invention and the technical solution of the present invention. , accurate and in-depth understanding.

[0021] The ionic liquid used in the embodiment of the present invention was purchased from Mooney Chemical Technology (Shanghai) Co., Ltd., lithium bromide was purchased from Shanghai Aladdin Chemical Reagent Co., Ltd., and phytic acid was purchased from Zhejiang Xinyang Food Additives Company.

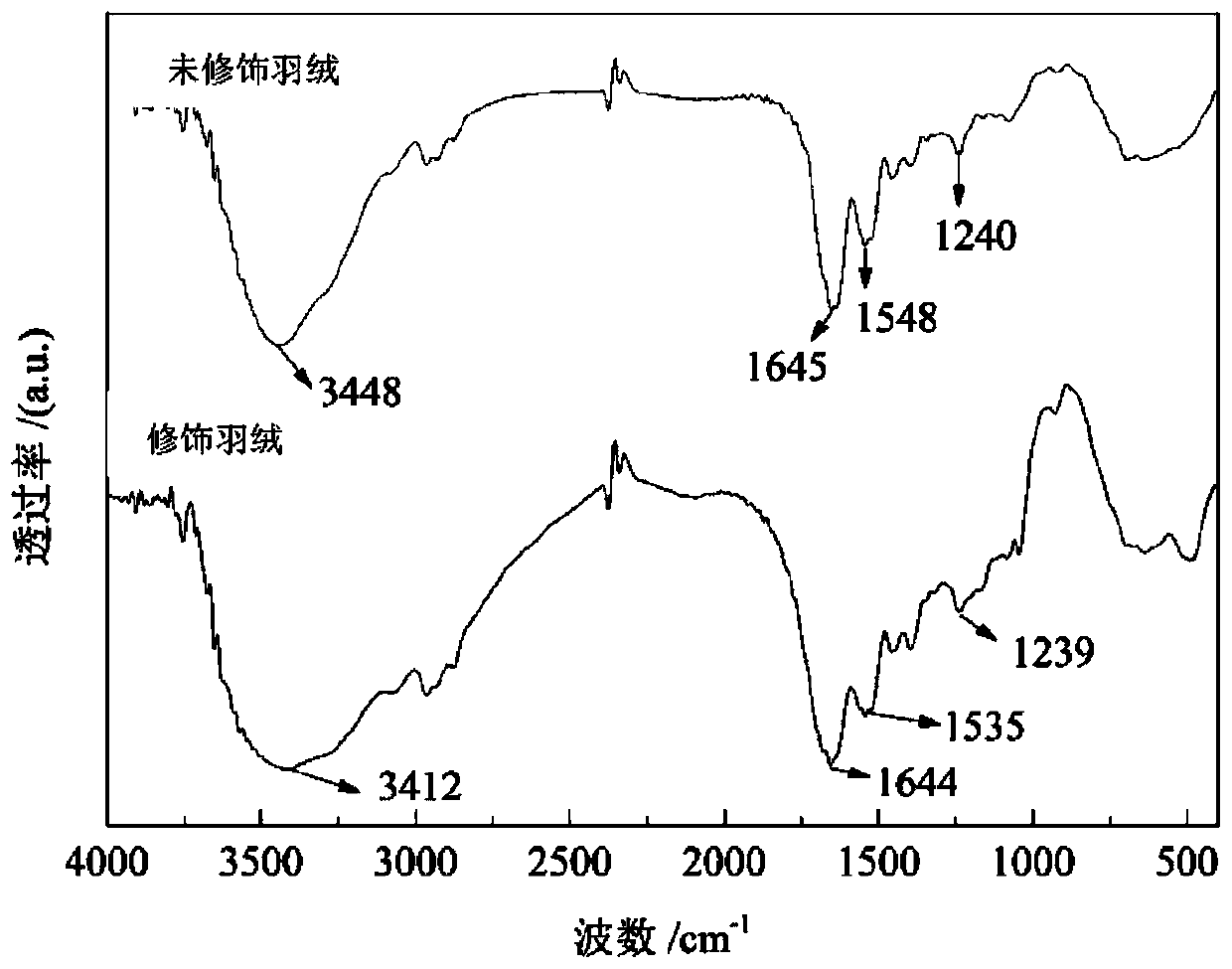

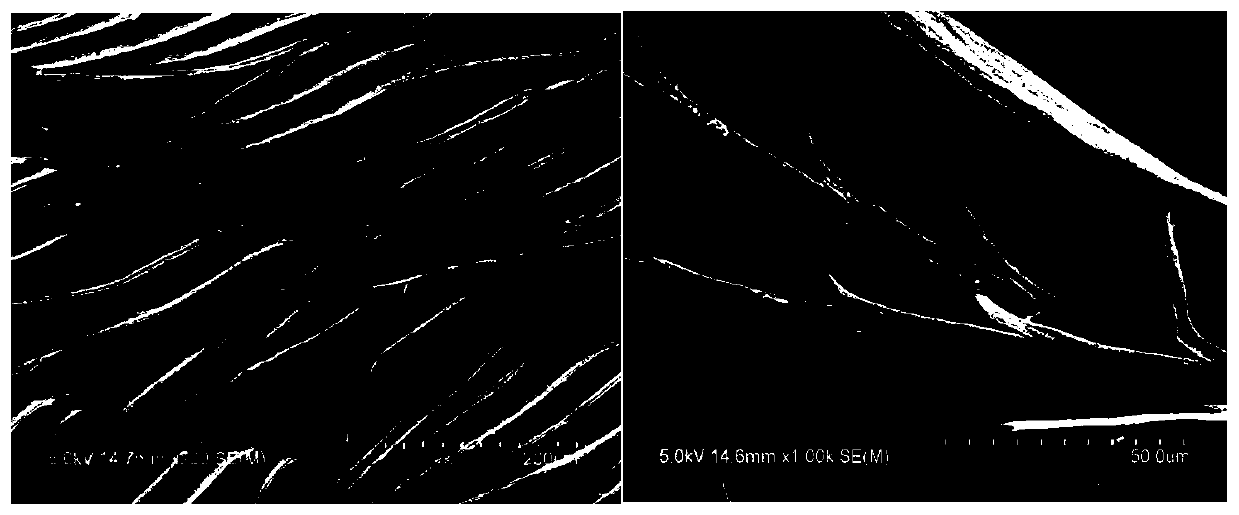

[0022] In order to change the reactivity of feather and down fibers to facilitate the improvement of the subsequent performance of feather and down, a method for modifying the surface of feather and down provided in an embodiment of the present invention includes the follow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com