Robot for detecting pipeline inner wall cracks and method of robot

A robot and detection mechanism technology, applied in special pipes, pipe components, mechanical equipment, etc., can solve the problems of missed inspection and easy omission, and achieve the effect of preventing omission and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

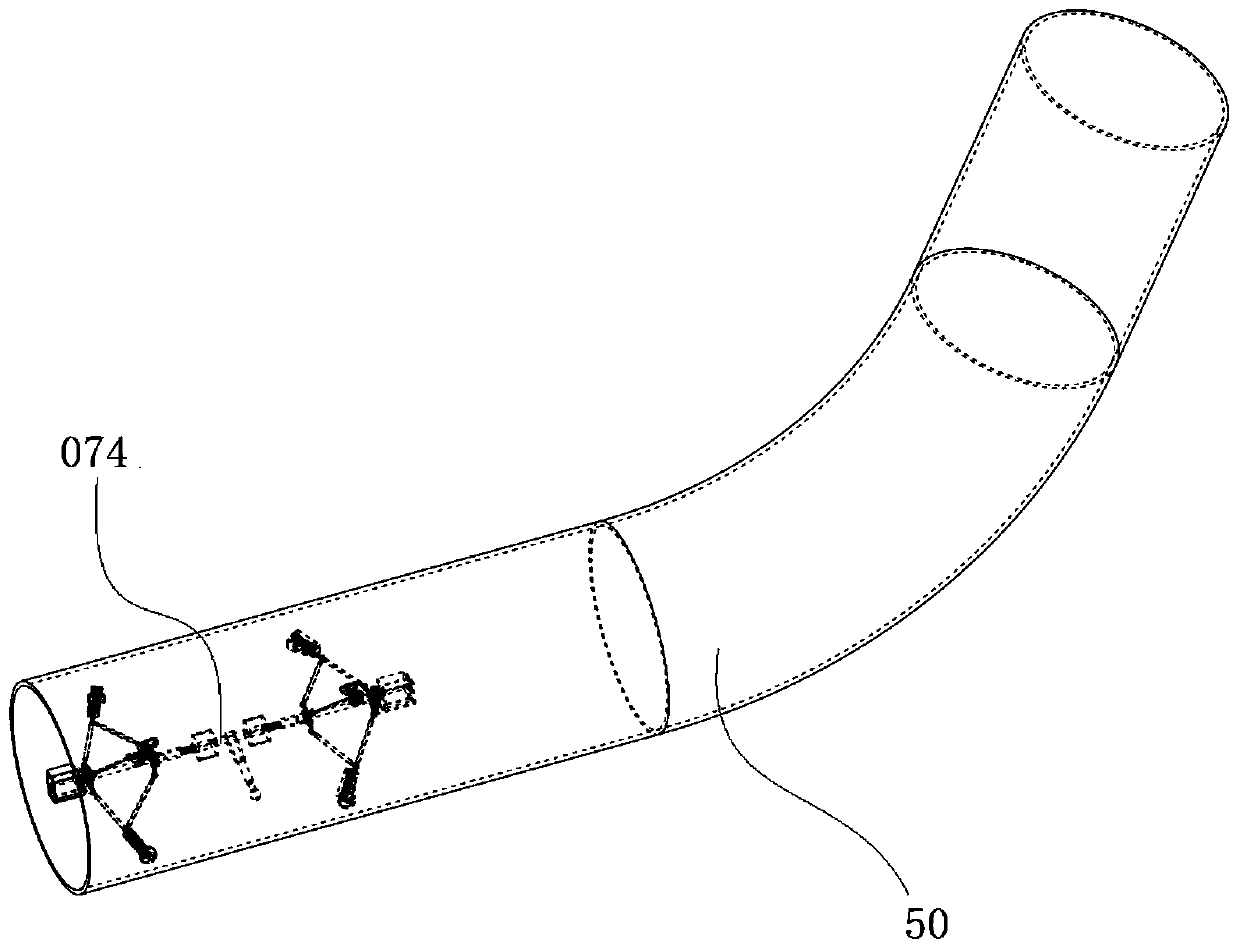

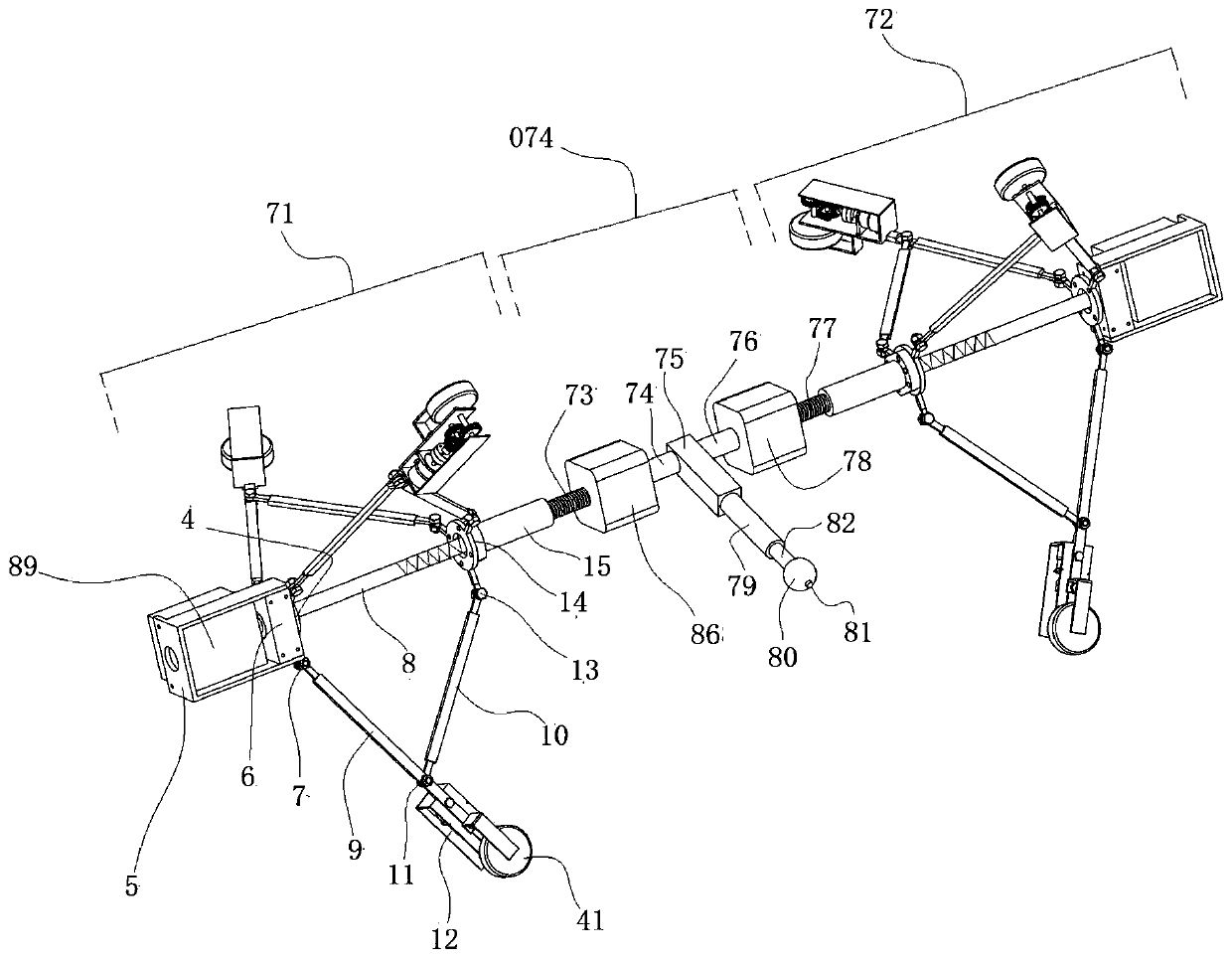

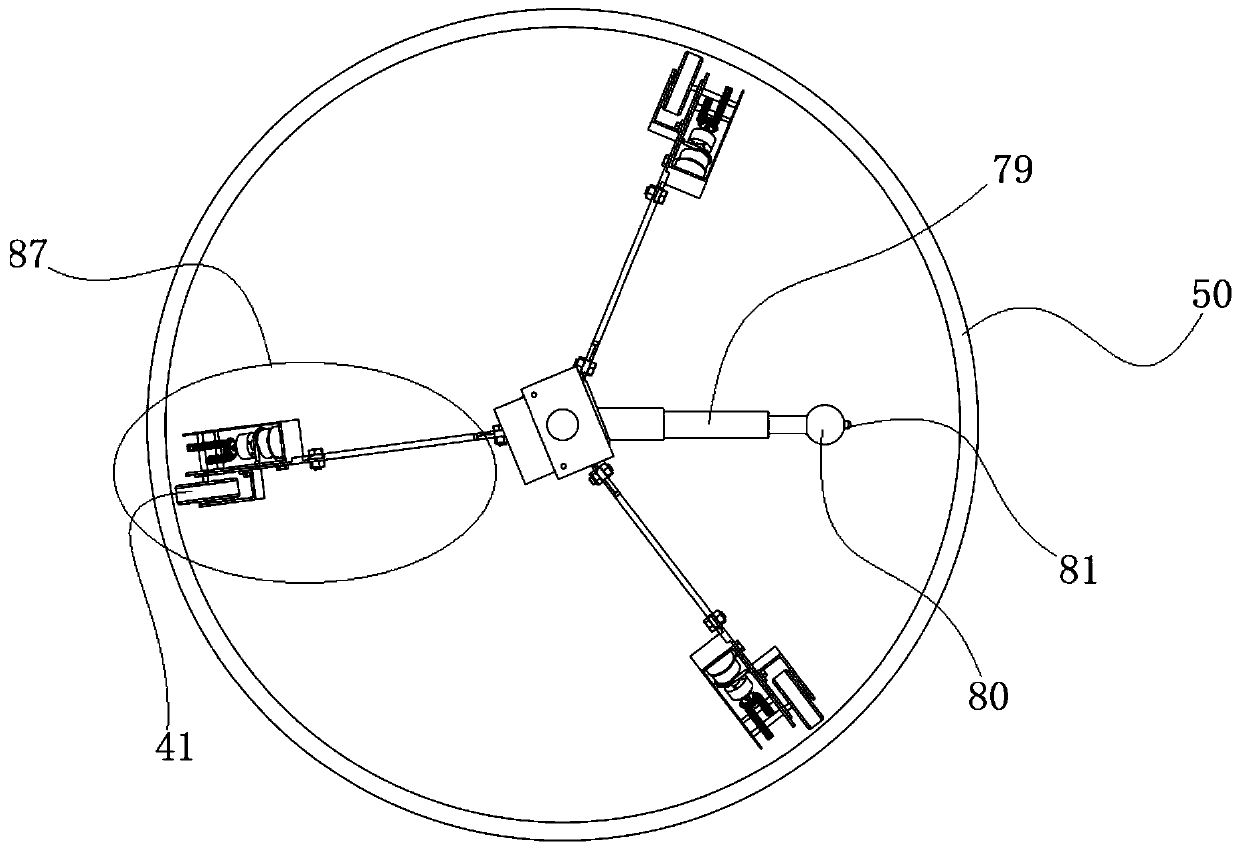

[0019] as attached Figures 1 to 3 The shown robot for crack detection on the inner wall of the pipeline includes a crack detection mechanism 074, and the front and rear ends of the crack detection mechanism 074 are symmetrically connected to a front travel unit 71 and a rear travel unit 72 through a front support spring 73 and a rear support spring 77 respectively; The front traveling unit 71 and the rear traveling unit 72 can drive the crack detection mechanism 074 to travel along the inner wall of the pipeline under test 50;

[0020] Described crack detection mechanism 074 comprises front and rear symmetrical front synchronous motor 86 and rear synchronous motor 78, so the end of the front output shaft 74 of front synchronous motor 86 is fixedly connected with the end of the rear output shaft 76 of rear synchronous motor 78; The connection between the front output ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com