Preparation method and application of a covalently modified high-density crown ether functionalized porous adsorbent

A porous adsorbent, covalent modification technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of the adsorbent ligand modification density needs to be improved, it is difficult to meet the high efficiency lithium extraction, modification density adsorption capacity and other problems, Achieve short adsorption equilibrium time, improve adsorption capacity and mass transfer efficiency, and increase the effect of high density sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

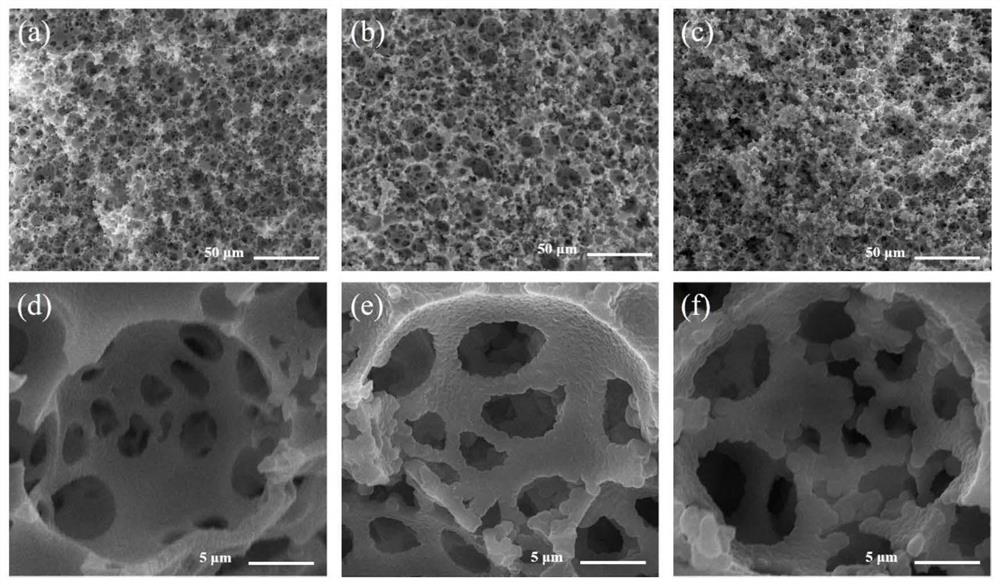

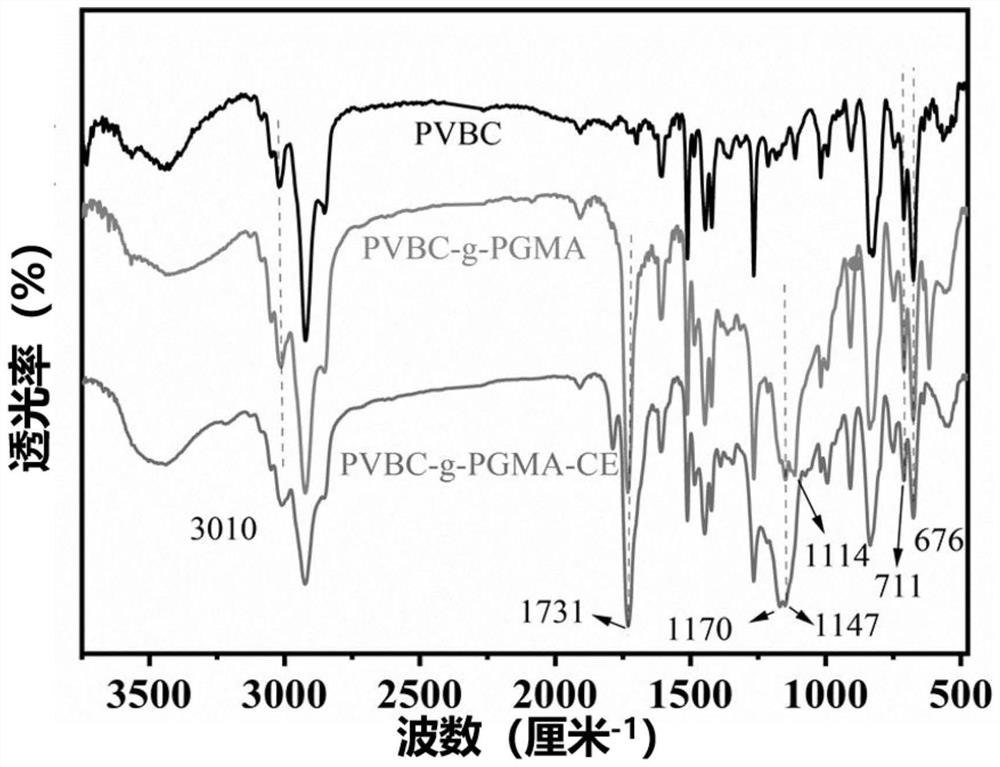

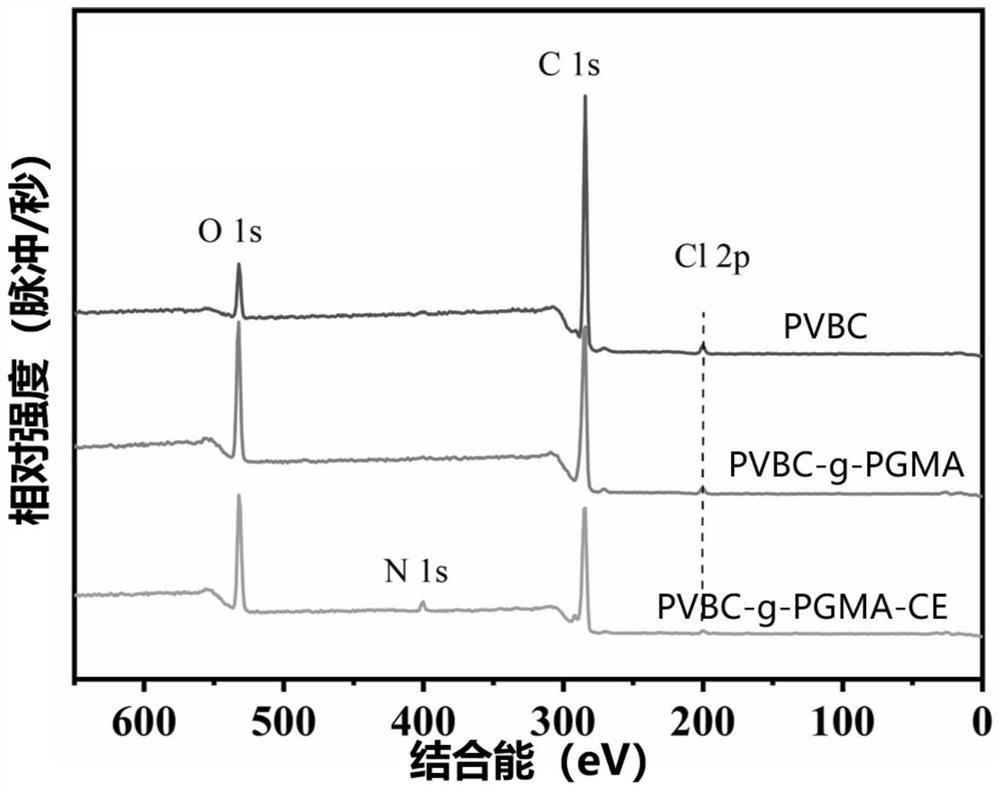

[0043] (1) Preparation of porous polymer (PVBC);

[0044] Add 0.5mL EGDMA, 3.0mL4-VBC, and 30mg AIBN into a 100mL three-neck flask, and sonicate for 5.0min to completely dissolve AIBN. Under mechanical stirring at 500rpm, slowly add 1.0mL Hypermer 2296 to the flask, after mixing well, slowly add 16mL 0.2 M K 2 SO 4 solution; increase the mechanical stirring speed to 800rpm and stir for 2.0min to obtain milky white HIPEs. The prepared HIPEs were transferred into glass ampoules and sealed. The ampoule was polymerized in an oil bath at 70°C for 24 hours, and the obtained porous polymer (PVBC) was purified by a Soxhlet extractor. The solvent used for purification was acetone to remove the internal phase of HIPEs and residual reactants. After purification, Put the PVBC foam into a vacuum oven at 60°C for drying;

[0045] (2) Preparation of a porous polymer (PVBC-g-PGMA) grafted with polyglycidyl methacrylate (PGMA) on the surface;

[0046] Mix methanol, DMF and anisole at a vo...

Embodiment 2

[0050] (1) Preparation of porous polymer (PVBC);

[0051] Add 0.5mL of EGDMA, 2.5mL of 4-VBC, and 25mg of AIBN into a 100mL three-neck flask, and ultrasonicate for 5.0min to completely dissolve AIBN; under mechanical stirring at a speed of 500rpm, slowly add 1.0mL of Hypermer 2296 into the flask, mix well, and add Slowly add 15 mL of 0.2 M K to the flask 2 SO 4 solution, increase the mechanical stirring speed to 800rpm and stir for 2.0min to obtain milky white HIPEs. The prepared HIPEs were transferred into glass ampoules and sealed. The ampoule was placed in an oil bath at 70°C for 24 hours, and the obtained porous polymer (PVBC) was purified by a Soxhlet extractor (solvent was acetone) to remove the internal phase of HIPEs and residual reactants, and the purified PVBC foam Transfer to 60°C vacuum oven for drying for later use;

[0052] (2) Preparation of a porous polymer (PVBC-g-PGMA) grafted with polyglycidyl methacrylate (PGMA) on the surface;

[0053] Mix methanol, D...

Embodiment 3

[0057] (1) Preparation of porous polymer (PVBC);

[0058] Add 0.5mL EGDMA, 3.5mL4-VBC, and 35mg AIBN into a 100mL three-necked flask, and sonicate for 5.0min to completely dissolve AIBN. Under mechanical stirring at 500rpm, slowly add 1.0mL Hypermer 2296 dropwise to the flask, after mixing well, slowly add 17mL 0.2 M K 2 SO 4solution. Increase the mechanical stirring speed to 800rpm and stir for 2.0min to obtain milky white HIPEs; transfer the prepared HIPEs into a glass ampoule and seal, place the ampoule in a 70°C oil bath for polymerization for 24h, and obtain the porous polymer (PVBC) Purify by Soxhlet extractor (solvent is acetone) to remove the internal phase of HIPEs and residual reactants, and the purified PVBC foam is transferred to 60°C vacuum oven for drying for later use;

[0059] (2) Preparation of a porous polymer (PVBC-g-PGMA) grafted with polyglycidyl methacrylate (PGMA) on the surface;

[0060] Mix methanol, DMF and anisole at a volume ratio of 1:1:1 to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com