Rubber sleeve press fitting facility with automatic pressure keeping system and press fitting method

A rubber sleeve, automatic technology, used in metal processing equipment, metal processing, manufacturing tools, etc., can solve problems such as rubber sleeve wear, and achieve the effect of eliminating rubber sleeve rebound, saving time, and reducing work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

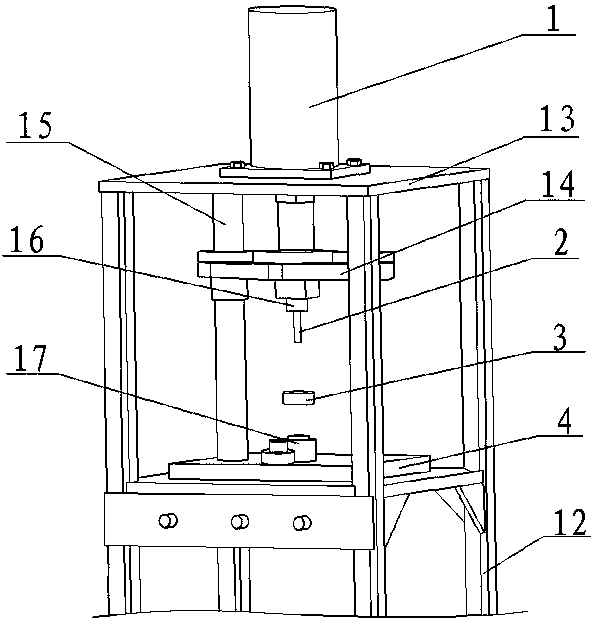

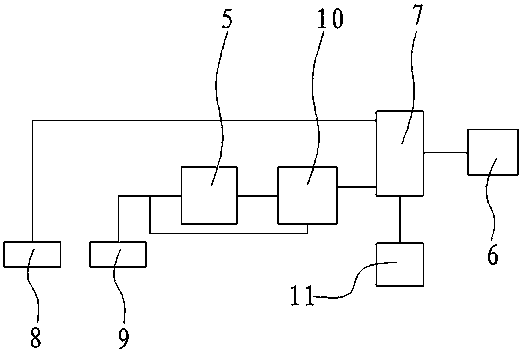

[0035] Such as figure 1 As shown, this embodiment provides a rubber sleeve press-fitting equipment equipped with an automatic pressure maintaining system, including a driving device 1, a pressure head 2, a guide sleeve 3, an operation bench 4 for placing a coupling, a start switch and Time relay 5; the output end of the driving device 1 is fixedly connected to the pressure head 2 to drive the pressure head 2 to move towards the operating platform 4. In this embodiment, the driving device 1 is Cylinder or hydraulic cylinder or electric cylinder, in the following description, the driving device 1 is illustrated by taking the cylinder as an example; the pressure head 2 is used to fix the rubber sleeve and press the rubber sleeve into the movement path of the pressure head 2 In the guide sleeve 3, the guide sleeve 3 is used to radially shrink the rubber sleeve, so that the outer diameter of the rubber sleeve after radial shrinkage is not greater than the diameter of the seat hole ...

Embodiment 2

[0044] This embodiment provides a rubber sleeve press-fitting method equipped with an automatic pressure maintaining system. The rubber sleeve press-fitting equipment equipped with an automatic pressure maintaining system as described above is used to press the rubber sleeve, including the following steps:

[0045] Step 1, put the rubber sleeve on the pressure head 2, absorb and fix the rubber sleeve through the magnetic suction part 16, place the coupling on the operating platform 4, and position the coupling through the coupling spacer 17 Placement, the guide sleeve 3 is placed at the rubber sleeve installation hole of the coupling, so that the rubber sleeve, the coupling rubber sleeve installation hole and the guide sleeve 3 are coaxial;

[0046] Step 2, press the start switch, the system is powered on, the driving device 1 starts to run, the driving device 1 drives the rubber sleeve on the indenter 2 to move toward the guide sleeve 3, and presses the rubber sleeve into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com