Forming process of a straddle mower dust cover

A forming process and technology of dust cover, applied in the field of forming process of dust cover of straddle lawn mower, can solve the problems of decreased service life of equipment, increased loss, rust of parts, etc., so as to prolong the service life and eliminate the The effect of rebounding and increasing the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

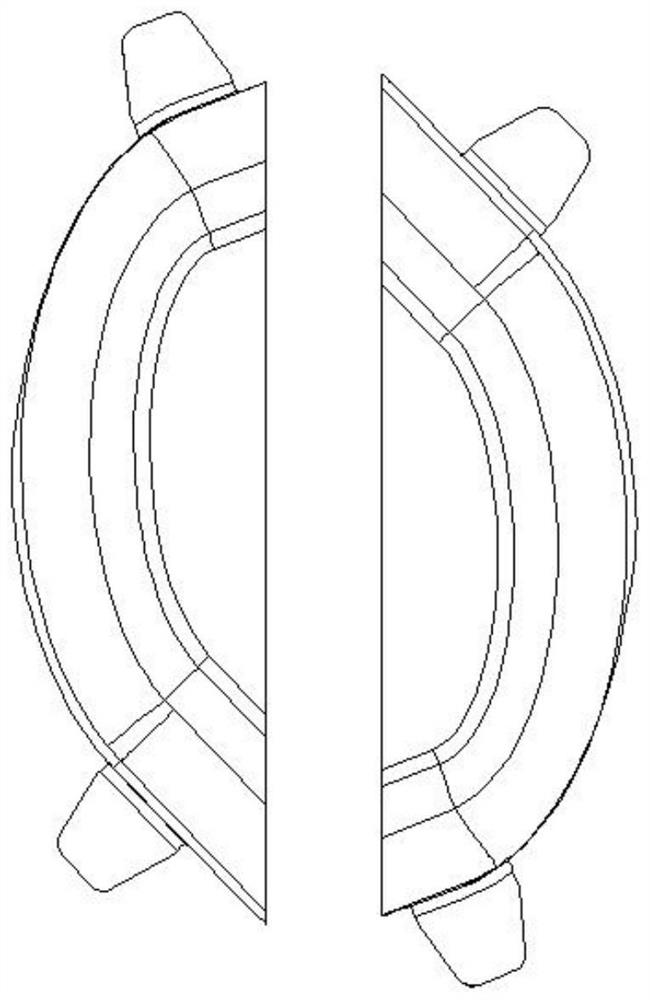

[0021] The dust cover is prepared by blanking punching-curved surface forming-positioning forming-cutting-punching in sequence, and the process steps are as follows:

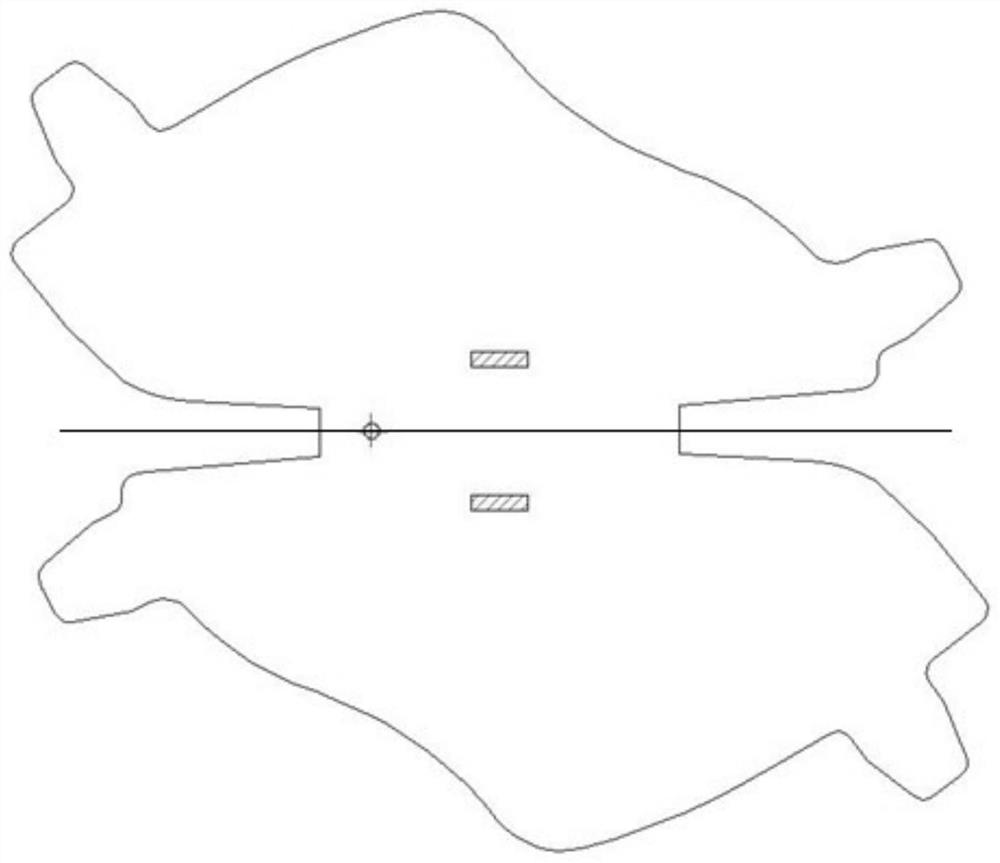

[0022] Step 1. Blanking and punching: Cut the plate into a sheet of the size required by the product. In this embodiment, the material of the plate is a cold-rolled plate with a thickness of 1.8 mm. The sheet material has an irregular pattern. In the press, put the sheet material into the blanking punching die to prepare the substrate, and position the two sides of the sheet material into the mold for blanking. The prepared substrate is symmetrically arranged on the horizontal line Irregular shapes, such as figure 1 Shown is a schematic diagram of the blanking and punching process in the dust cover of a straddle lawn mower. There are four ears on the base plate, and the four ears are arranged symmetrica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com