Adjustable offshore large wind power blade lifting appliance and lifting method thereof

A technology for wind turbine blades and hangers, applied in the field of wind turbine hoisting, which can solve the problems of inability to install hooks and large dimensions of offshore wind turbine blades, and achieve the effects of high strength, low design cost, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

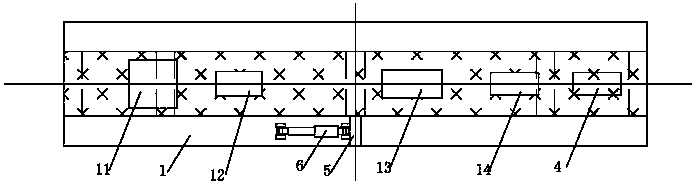

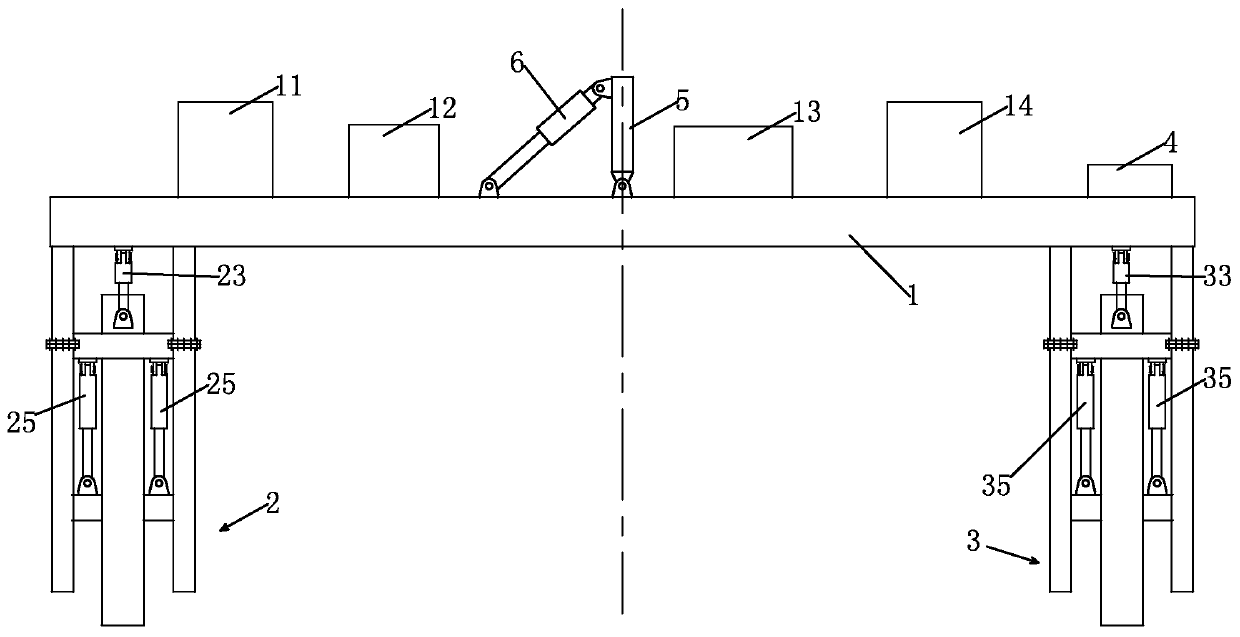

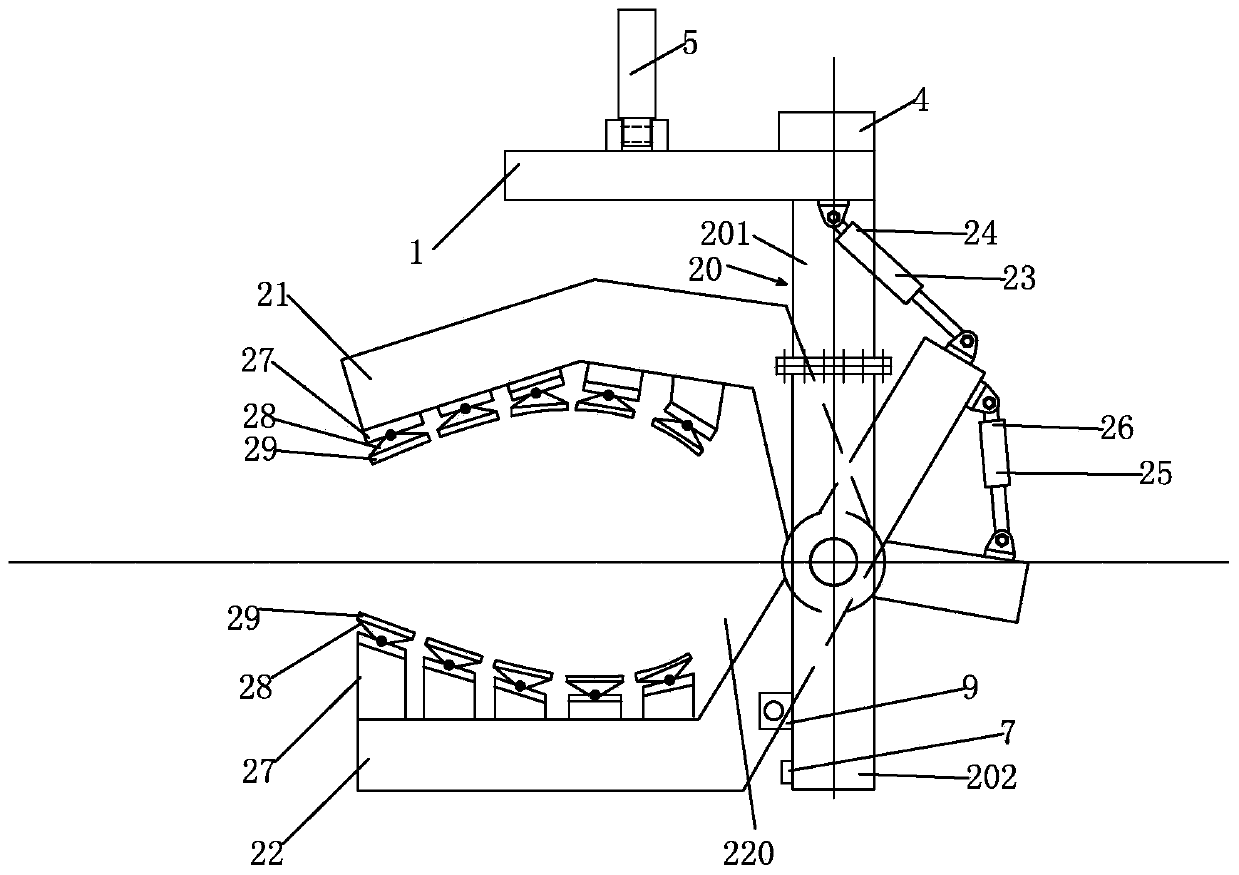

[0041] like figure 1 and figure 2 As shown, the adjustable offshore large-scale wind power blade hanger of the present invention includes a platform 1 , a blade root end clamp 2 , a blade tip clamp 3 , a counterweight 4 , a swing arm 5 , and an adjustment hydraulic cylinder 6 . The platform 1 is a cuboid made of hollow steel structure, which is used for blade root end clamps, blade tip clamps, adjusting the installation and positioning of hydraulic cylinders and setting the lifting points of hoists or cranes. The swing arm 5 is hinged on the upper surface of the platform 1, and the center of the upper end surface of the swing arm 5 is provided with a lifting point. The blade root end clamp 2 is connected below the left end of the platform 1 , the blade tip clamp 3 is connected below the right end of the platform 1 , and the counterweight 4 is installed above the right end of the platform 1 . One end of the adjustment hydraulic cylinder 6 is hinged with the swing arm 5 , and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com