Automatic feeding device for washing additives and washing machine

A technology of automatic feeding and additives, which is applied in the field of washing machines, can solve the problems of complex assembly, false alarms, and increased costs, and achieve the effects of sensitive detection results, easy installation, and cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

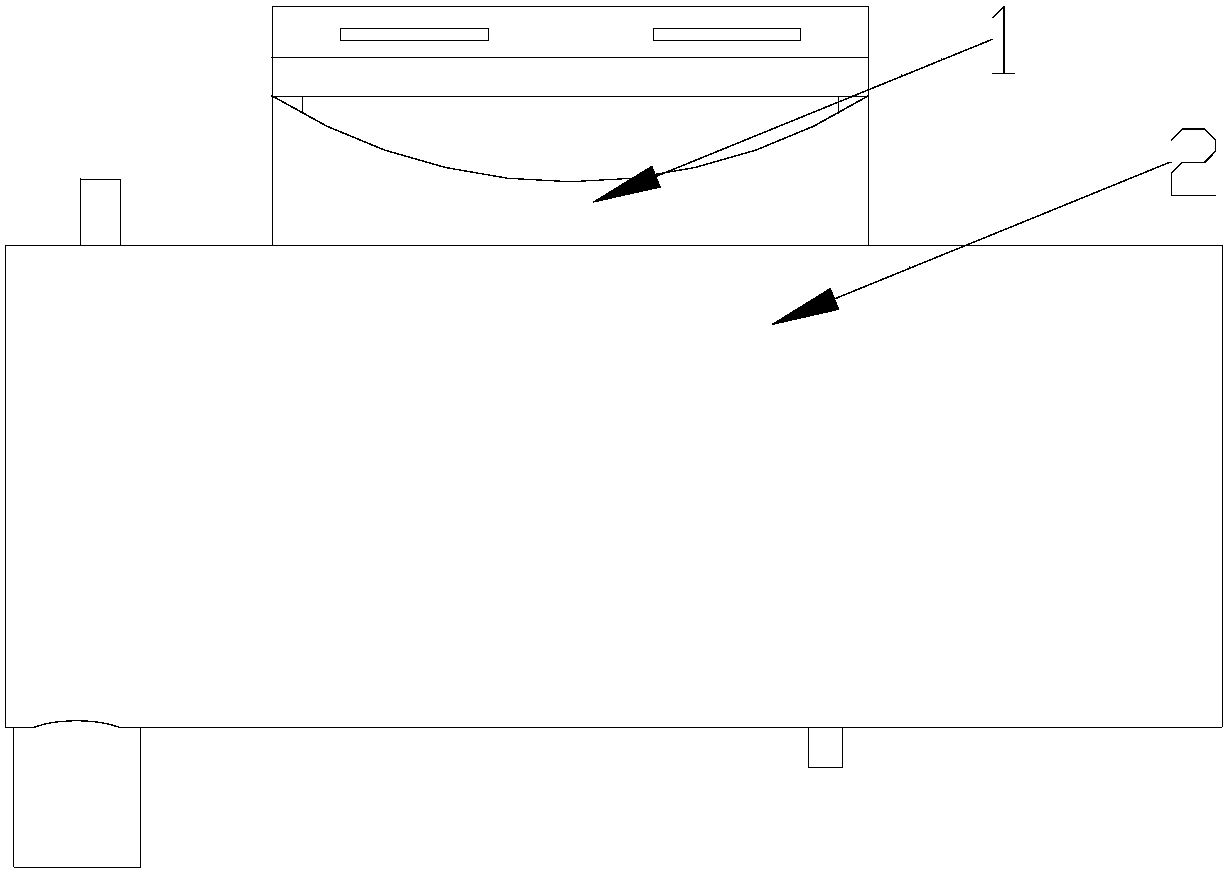

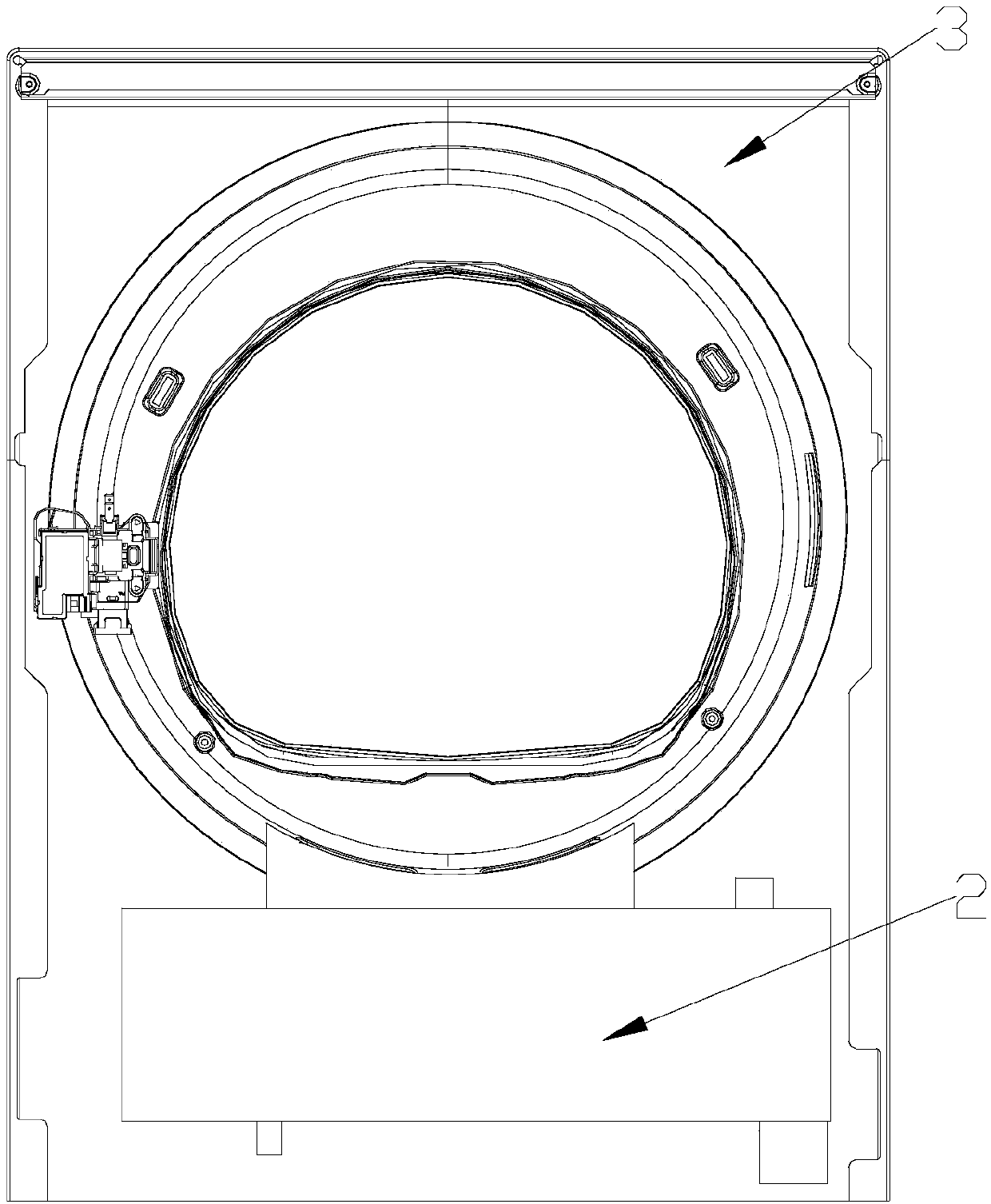

[0034] Such as Figure 1-2 As shown, in this embodiment, a device for automatically dispensing detergent additives includes a container 1 for holding detergent additives and an installation part 2 for carrying the container 1. The container 1 is set in the installation part 2 in a removable manner. It includes at least one set of liquid level detection structures for detecting the liquid level inside the container 1 .

[0035] In the above solution, because the container 1 is generally connected with various pipelines, it is difficult to take out the container 1 for liquid replenishment and other operations, requiring professional maintenance personnel to operate, which causes great inconvenience for users to replenish detergent additives. The container 1 of the present invention is set in the installation part 2 in a removable manner, so that it is convenient to take out the container 1 for liquid replenishment maintenance and other operations. Because the automatic detergen...

Embodiment 2

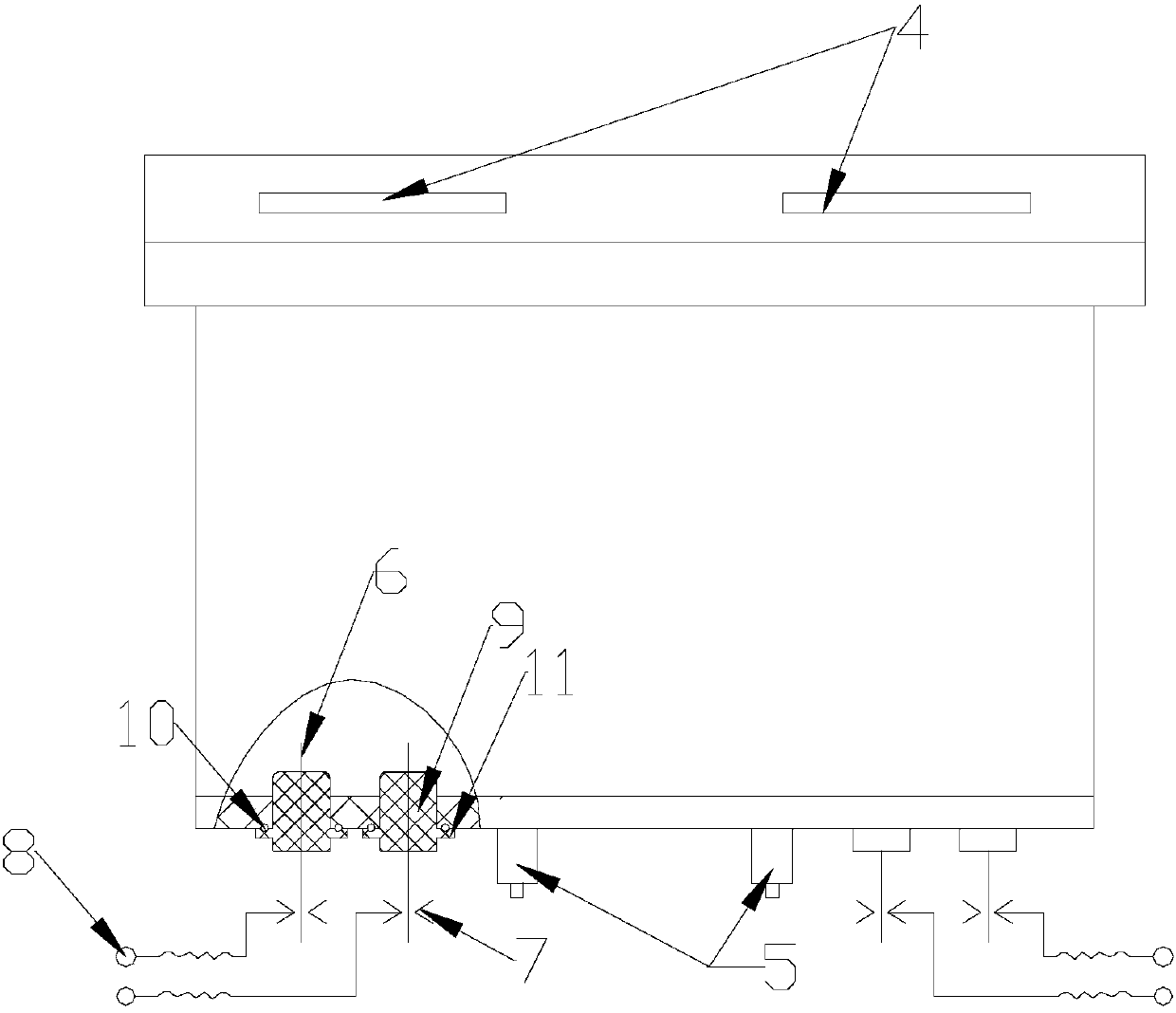

[0041] This embodiment serves as a further limitation to Embodiment 1. In this embodiment, the liquid level detection structure further includes a fixed part 9, and the detection part 6 is sealed and wrapped in the fixed part 9, and both ends protrude from the fixed part 9. It is provided that one end of the detection part 6 is detachably sealed and inserted into the container through the fixing part 9 , preferably, the fixing part 9 is connected with the container 1 through threads.

[0042] In the above solution, the fixing part 9 may be made of insulating material, and the fixing part 9 inserts the detecting part 6 into the container. The fixing part 9 itself is not inserted, and the function of the fixing part 9 is to seal and fix the detection part 6 at this time, making it easier to seal and connect with the container 1 .

Embodiment 3

[0044] This embodiment serves as a further limitation to Embodiment 2. In this embodiment, one end of the detection part 6 is detachably sealed from the bottom of the container 1 through the fixing part 9 and inserted into the container. The fixing part 9 is made of insulating material. The fixing part 9 is at least partially inserted into the container, and the height from the top of the inserted part to the bottom of the container is the lowest measurable liquid level.

[0045] In the above scheme, the detection part 6 of the liquid level detection structure according to the present invention is inserted into the container from the bottom of the container 1, which is more convenient for detecting whether the washing additive in the container is sufficient, and at the same time, because the liquid outlet 5 is also arranged at the bottom, it is arranged at the bottom of the container. The bottom is easy to install, and no other structures are added, which saves costs. In this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com